Posted by Jim Beagley on 19/05/2020 11:08:13:

Hi all.

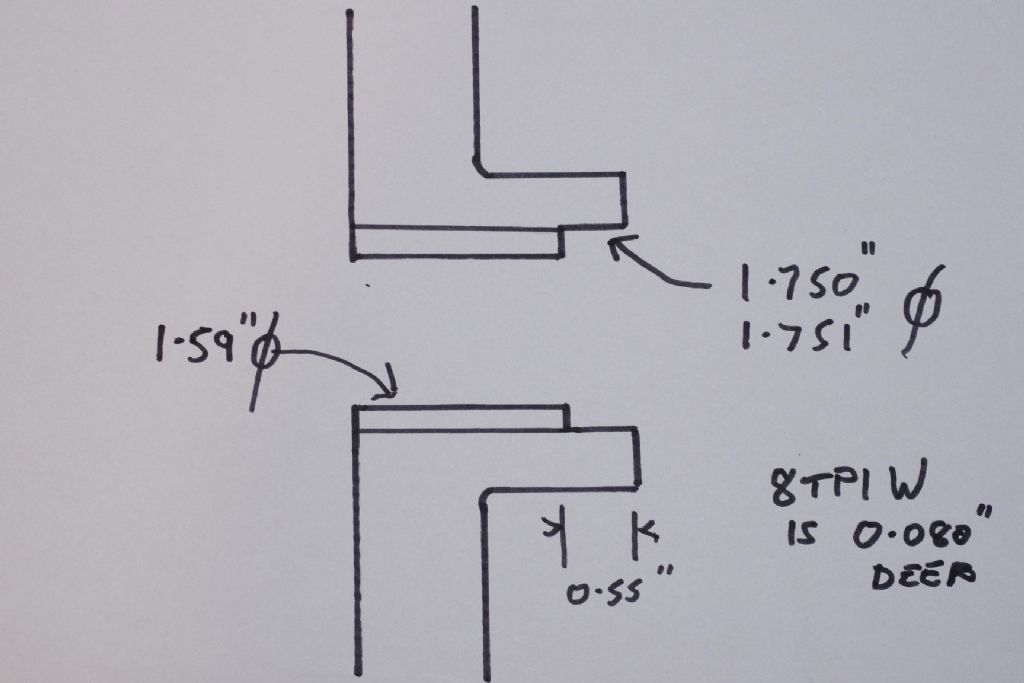

I own a Sabel lathe and one part I am struggling to source is the back plate with a 1-3/4×8 thread.

with this in mind my long term goal is to be able to cut that thread onto a blank but I’ve never attempted threading on the lathe.

I am now looking at carbide tooling for internal and external threading but need some advice.

How does a boring bar differ from an internal threading bar? Is it just the inserts required?

What is would the thread form be for the back plate and do I need inserts appropriate to the thread form?

Is it reasonable to purchase some Glanze tooling now so I can make a start?

Can I get some Top Tips for my first lathe threading Exercises?

sorry for the long post, and thanks for any responses,

Best, Jim

Hi Jim,

FWIW I buy and use carbide inserts for threading, only because it a right royal pain to grind HSS tool bits accurately.

The only difference between insert tooling boring bars and threading bars is the shape and set angle of the carbide insert. Internal and external inserts have the cutting tip on opposite sides.

Having said that, I also thread external threads using an internal threading insert on the rear of the work and run the lathe in reverse cutting away from the chuck. No danger of crashing into the chuck.

For internal threads such as your face plate where you can thread right through, I use the same internal threading tool but thread in the conventional manner. For blind holes it is safer to use a lathe handle and wind the lathe backwards and using a normal external threading insert cutting from the inside away from the chuck.

I also just plunge, no messing about setting the top slide at 29 degrees. One other recommendation I can add, is to make an accurate test thread so you can gauge the thread without having to remove the chuck to test the fit.

Last thing make sure you use the correct thread angle, some are 60 degrees, some are 55 degrees and there are some others. Metric threads are usually 60 degrees. I don't know your lathe, but I would get some thread gauges and check it.

HTH.

Jim Beagley.