Some more progress.

Here is the unit set up temporarily on my grinding bench. I've bought a CBN wheel and fitted it to my ELU grinder (much easier than I expected, though I need to extend the guard to cover the wider wheel). Note that I have replaced the lever screw that clamps the cutter holder with a brass thumb screw – this is easier to use as the lever I found didn't give enough rotation to clamp the holder without fouling the tool block, so you had to take the tool block out of its slide. Also I found that the square end on the holder, which indexes the cutter, fouled on the bottom of the slot in the tool block and prevented the latter sitting snugly in the slot. The tool block is made 25mm square but the square flange on the holder was 25.4mm, 1", as shown in the drawing. This doesn't seem right to me so I milled a shade off each face of the square down to 25mm and it now fits much better.

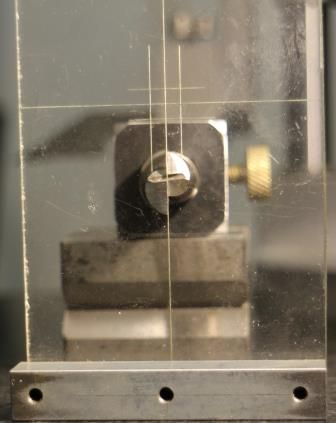

In order to align the cutter to the sides of the square holder I used a simple optical aid I made years ago.

This is a scrap of perspex screwed onto a bit of square bar sitting on my surface plate. The tool block perches on a Vee-block (just for height). There's a vertical line scribed on the perspex and you just align the cutter edges to this as in the photo. I'll get around to making a dedicated version for the Acute later (when a get a "tuit" I expect).

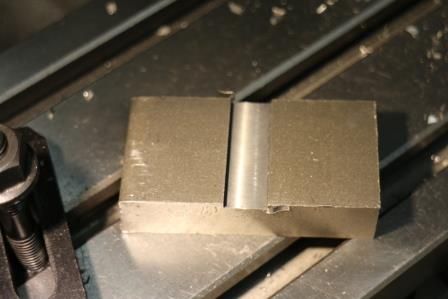

I've had a go at 2 cutters so far. The first was a 1/2" end mill, which I now realise had been sharpened quite a lot before I got it (very surplus). This tirned out to really need re-gashing so the sharpening didn't go well – back into the "too sharpen" box with it! So then I tried a 1/2" slot drill, shown mounted in the photo. This went fine, here is the result.

Mounted this on the mill and took a trial cut on a block of mild steel, feeding the cutter straight down as shown in Gary's example video, about 2.5mm, then elongated the hole into a slot. The mill cut very nicely, making a nice "chuffing" sound and freely generating chips. Obviously it sharpened well – here is the end result –

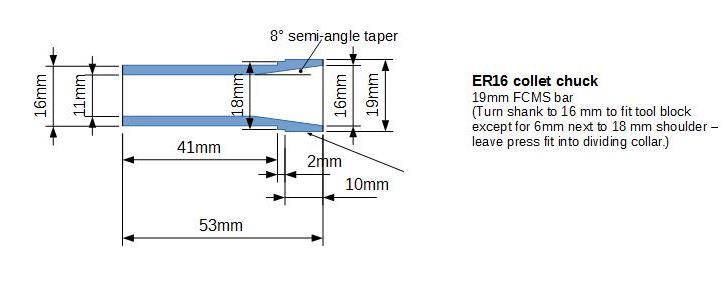

Things to do still…make a 12mm holder…make the ER16 holder with a 12-sided dividing flange (drawn up but needs making)…make a slotted tool block for grinding lathe tools (especially for my "Diamond" tool holder)…tidy up the grinder by making a wider guard and mounting the whole caboodle on its own base…and get a lot of practice!

Edited By John Haine on 13/12/2015 17:13:26

Dave Cee.