Hi there, Steve,

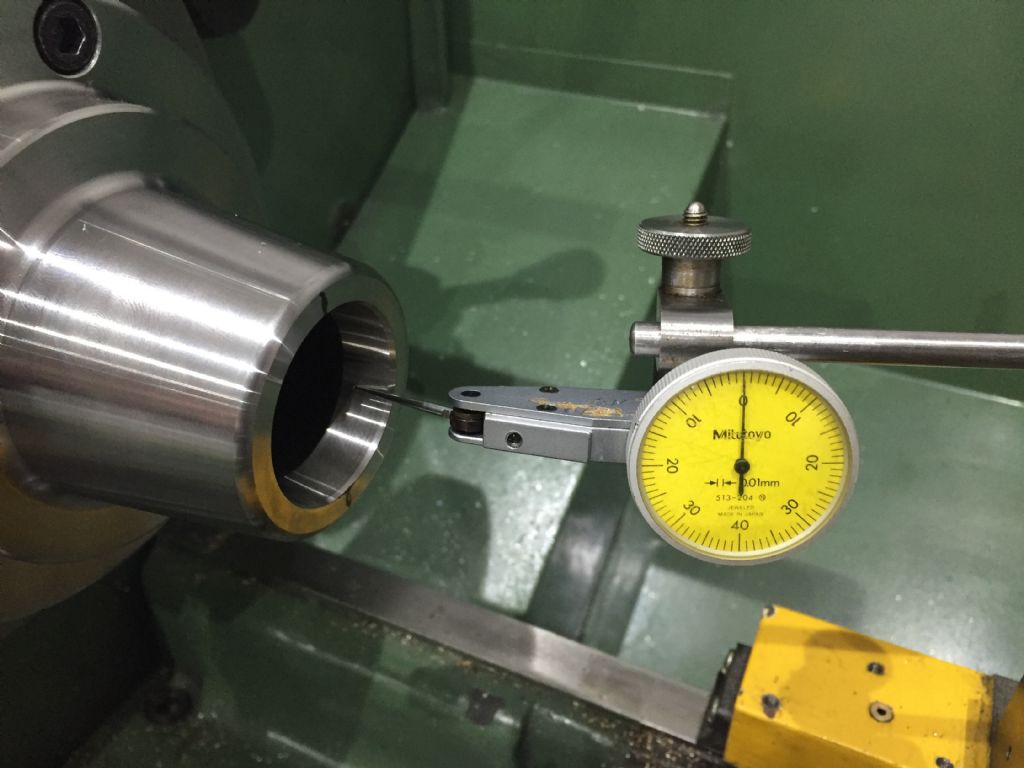

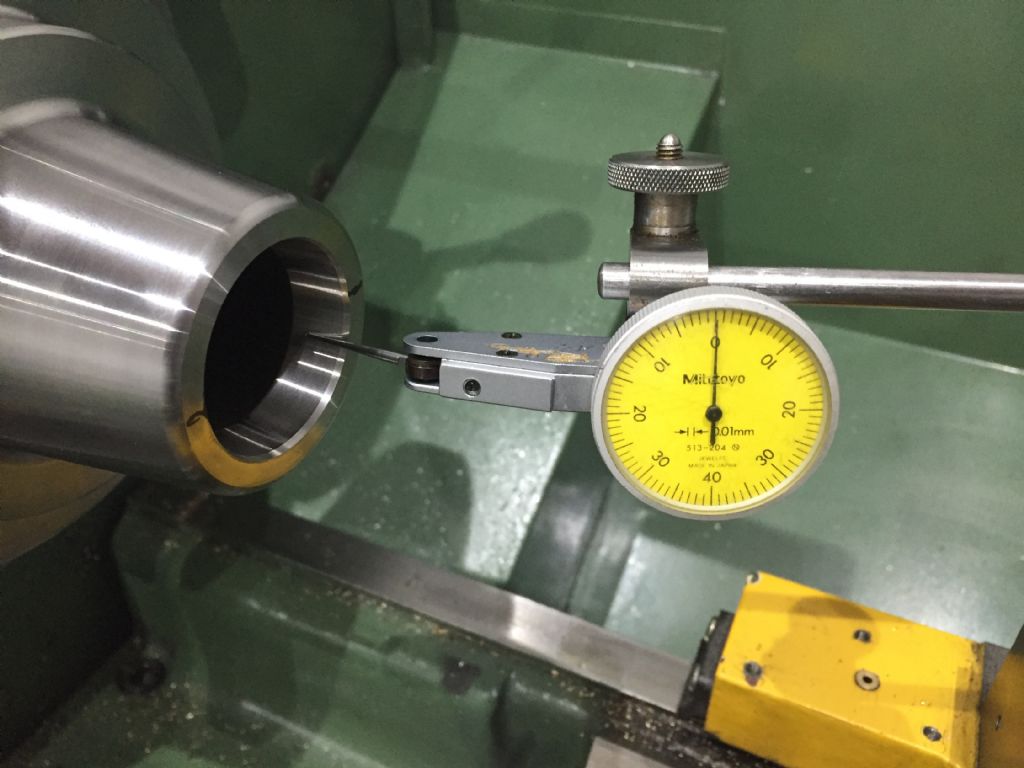

Just a suggestion: Take your plunger-type dial gauge in to your friendly metrology emporium and ask them if they can supply you with an 'elephant's foot' tip for the plunger. (The ball-end tip should unscrew to allow other tips to be fitted. ) The flat or 'elephant's foot' type has the advantage when 'clocking' round stock, especially small diameters, that you don't need to present the probe so precisely to the job.

The reason I suggest taking the gauge with you is that there are two standard screw threads, metric vs unc. so it's good to be able to 'try before you buy' !

Being able to visit the emporium gives you the great advantage that the cost of the extra tip won't be swamped by P&P costs and the transaction won't be burdened by the minimum order charge imposed by some tool suppliers.

Best regards from my armchair,

Swarf, Mostly!

Edited By Swarf, Mostly! on 23/01/2016 11:18:22

Chris Evans 6.