I beg to differ.

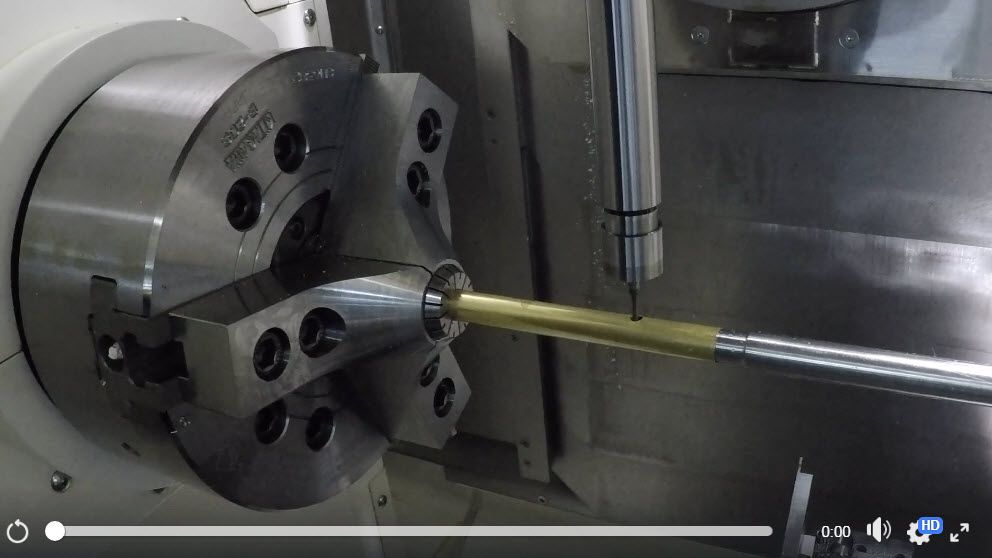

The workpiece is a thin wall tube, while it would be easy to make a special set of soft jaws to hold the part, using this method will allow an easy change to a wide range of sizes.

The chuck itself is fitted to a high end CNC machine, I am guessing that the the hydraulic chuck body is very high accuracy and that the soft jaws were bored in situ dead true.

I have always suspected the ER system's main flaw is that the front taper is centered by a screw cap. I have seen a number of experienced machinists videos that show the cap being given a smart tap with a soft hammer to improve the centering of the cap.

I think this is a good solution, Looking at the other videos on the site it appears the shop produces a lot of differing small parts.

Does it produce parts that are within spec efficiently? that is the only question that needs to be answered.

Joseph Noci 1.