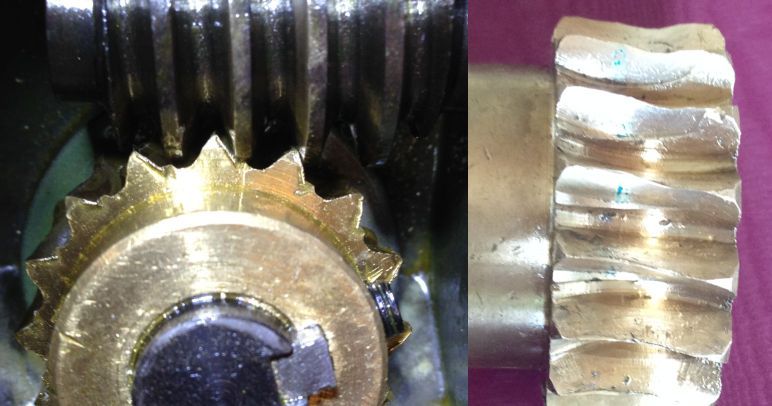

I noticed that my 10 year old CY90 bandsaw has been leaking oil slightly via the driveshaft. On closer inspection this time, the oil was loaded with fine brassy material, so decided to open the gearbox and take a look and found it to have become mysteriously filled with 'antique gold' paint.

The pictures say it all realy… dissapointing as the machine has not been used hard in its life, the original 14t carbon steel sawband was still going strong before I dismantled it. BTW, for anyone contemplating dismantling, it was a right sod to get apart – everything seems to have been assembled using oversized shafts and tectonic forces. A bloody good 3 leg puller and a suitable hydraulic press is required.

As far as I could tell the driveshaft bearings seemed OK with no play or float and the worm appeared to be set correctly 90 degrees to the worm gear. The helix angle of worm and worm gear appear the same (approx 4.5 degrees)

I was wondering if anybody had a view as to the reason for the premature failure? How might this be prevented / mitigated in future?

I have purchased a new worm gear but as they are quite expensive, I would like to try to avoid having to replace them every few years (anticipate using the saw rather more in future).

New oil seals will be required, but as the unit is stripped down, would it be worth replacing the various shaft bearings as well?

As I have modified the saw to allow vertical use, Some fairly good sealing may be needed on the worm shaft as all the oil in the gearbox will be vertically above the drive shaft in that configuration. The present shaft bearing area will only accept one bearing oil seal as the centre portion between the fore and aft bearings has been machined undersize.

There is a thin walled tube spacer between the driveshaft bearings that I was considering replacing with something thicker, machined to accept internal and external O rings to seal both the shaft and bearing housing/spacer annulus. Just concerned that this is a fair bit of work and the o ring on the rotating shaft would wear very fast and become inefective.

Has anyone else come across these issues with this or similar bandsaws? I would certainly weclome the benefit of your eperience, ideas or solutions to these problems.

Truth is, it has been a good little saw, saves vast ammounts of effort, cuts straight and accurately and is very versatile with the usual mods and accessories.

Thanks,

Martin.

Martin of Wick.