12 pcs may not justify the method below, but for lg qty here's how I would do it on a home shop lathe. The method assumes you have a 4 or 6 position QC toolholder.

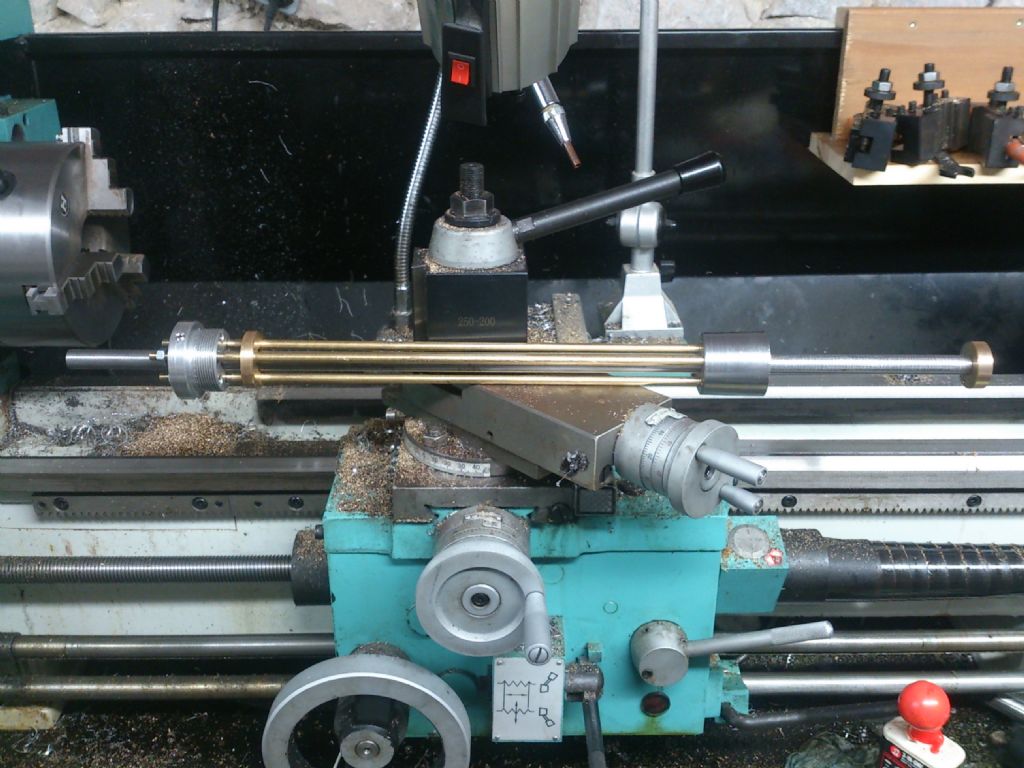

1. Make a two tool cutter with the HSS cutters mounted in a block 15 mm (plus or minus X within your tolerance) apart, and wide enough to cut the end dia's plus partoff tool width at headstock end.

2. set up above two tool cutter in toolholder, and set up a parting tool for next indexed op.

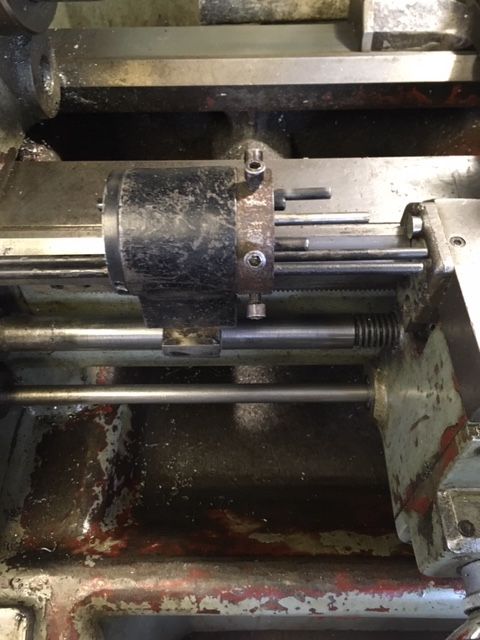

3. set up a work stop on the tailstock (could be just a rod in the drill chuck, and a removeable spacer so the stock doesn't rub on the stop) and arrange stock to feed through spindle hole up to spacer on stop. The stop and spacer should be set relative to the two tool cutter so cut is in correct place relative to stock end. Lock tailstock.

after setting up as above, ops as follows:

1. feed stock through spindle, through chuck or collet , to the spacer on the stop rod. Tighten chuck or collet.

2. remove spacer from stop rod.

3. make cuts to depth on ends with the two tool cutter, using cross slide (carriage locked).

4. index toolholder to the parting tool, to part off cleanly (no pip ideally)

5. replace spacer on stop rod. Index toolholder back to two tool cutter

6. repeat for next part.

Just my $0.02 worth. Done many like it. Standing by for the flaming. Just trying to offer simple practical methods.

Edited By Jeff Dayman on 23/01/2019 00:53:35

Clive Foster.