Good morning all,

Just reading the latest post from that member with the bum rotary table. WELCOME TO THE CLUB !! I too had hopes of doing some gear cutting at some stage,but I hate to think what they might turn out like,since even the chart supplied with my table is full of errors.

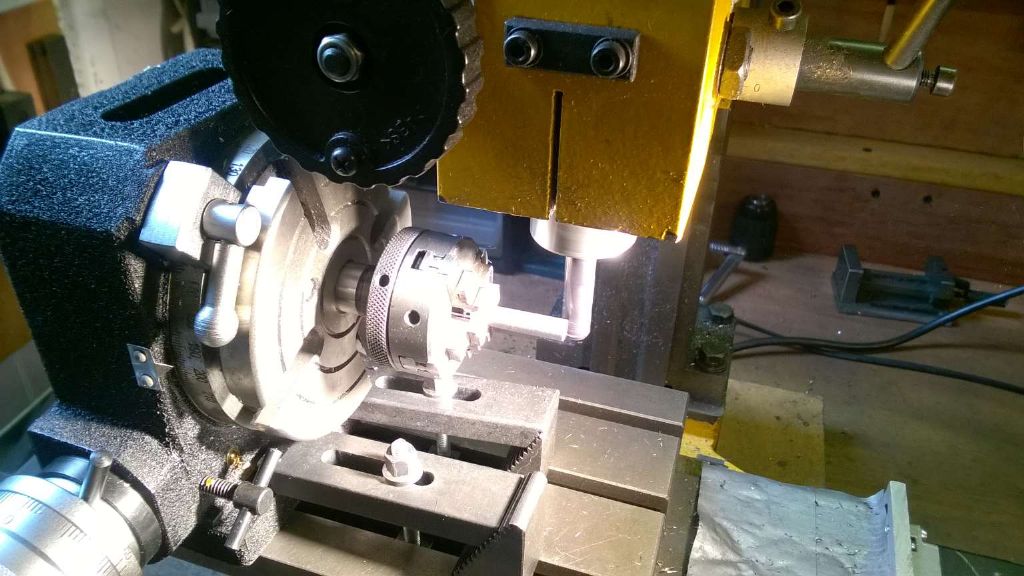

You can get fairly good results by using the 4 jaw chuck,it,s just a bit slow to set up and you do need to make a mount for it,but that,s no big deal,even I could manage to make one,and that,s saying something ! I had already made one,a copy of the lathe spindle,just a simple disc with a threaded nose on it and it works quite well.

I agree it,s very disappointing to find that the table is of limited use,but it may be possible to correct it,I hope to have a go at mine soon,thanks to Neil. I saw the one being offered by Warco and was tempted,but I think I might just hold fire. I hope you get a better response than I did [at least they still sell them ]

What is the point of selling stuff like this? Perhaps if they want to sell through M E W,they should have to meet proper standards. The word gets around fairly fast in these circles and if professionals wont accept such junk,why should we? I know they will say that these things are made to a price,but if they dont work,the price is irrelevant. Just some food for thought. This is how junk boxes evolve !.

Edited By JasonB on 26/03/2017 14:55:05

larry Phelan.