Andrew,

Yes you have it .

There is no G Code as such although it does make the moves you say. We looked at using the G19 plane, ie working in Y and Z instead of X and Y but it got very complicated quickly.

This is part of the code and is all you see on screen, there is no scrolling of numbers as you are used to seeing but rather two subroutines working behind the scenes.

#1=[30] ;BAR

#2=[15] ;PCD

#3=[10] ;PIN

#4=[18] ;Passes

#5=[0] ;A

#6=[1] ;Pass

G0 G21 G49 G40.1 G17 G64 G80 G50 G90 G98

M6 T1

M03 S4000

G00 G43 Z10.0

G00 A0.0 Y0.0 X5

M98 P003 Q#4

A0.00

M5 M9

M30

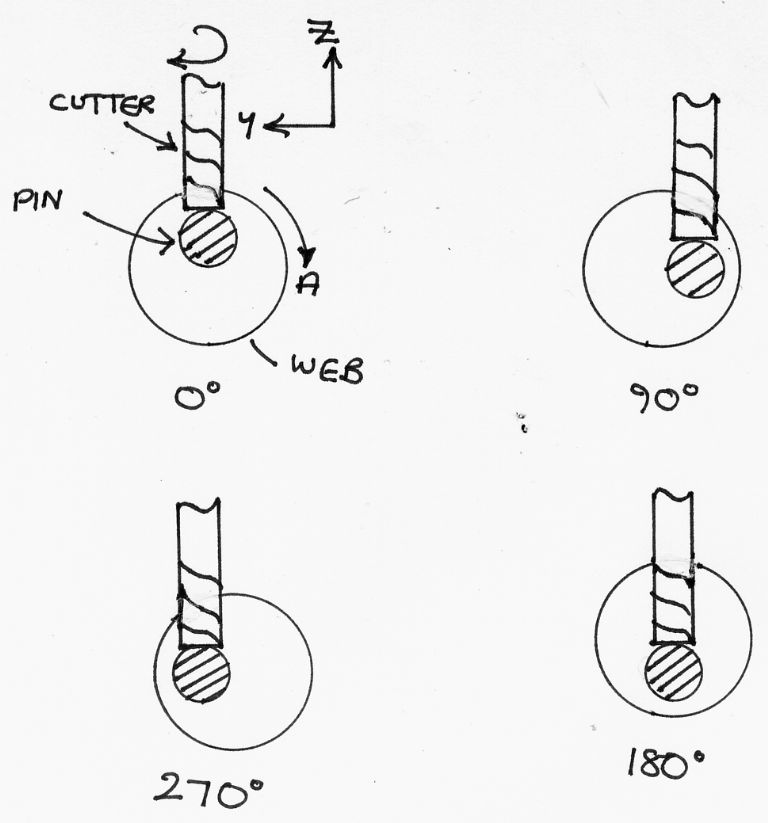

In the later part of the ‘code’ it calls a sub routine P003, that works out where the tool is in relation to A and Z.

That subroutine in turn calls another subroutine, P004 that works out where the tool is in relation to Y and Z.

The whole code is about double what is posted above. At the moment I don’t want to release this as it’s all the work of small son and I need his permission.

Good thing about this is it’s all powered by variables set out at the beginning so it will work for any crank throw. The figures in the variables are the ones relating to the crank we cut, 30mm OD, 10mm pin, etc.

Good point about the concave cutter, never thought to measure the edges as opposed to the centre, Perhaps we need a small grinder carried by the Z axis so it can go round and do a final clean up ?

John S.

Edited By John Stevenson on 04/11/2011 00:17:31

Mike.

? I am building the Whittle V8 and after bending the crank 5 or 6 times in the lathe it got put on the back burner. The dummy ones where made from mild steel which may have been part of the problem, but having not done any engine building before probably contributed as well.

? I am building the Whittle V8 and after bending the crank 5 or 6 times in the lathe it got put on the back burner. The dummy ones where made from mild steel which may have been part of the problem, but having not done any engine building before probably contributed as well.