Not sure if this is the right place,but here go,s anyway.

Some of you may remember that I asked for advice on gear cutting. The response was all I could have hoped for,and I thank everyone for their time and interest.Since then,I have made my first attempt at the subject and thought that you might be interested to know the results.

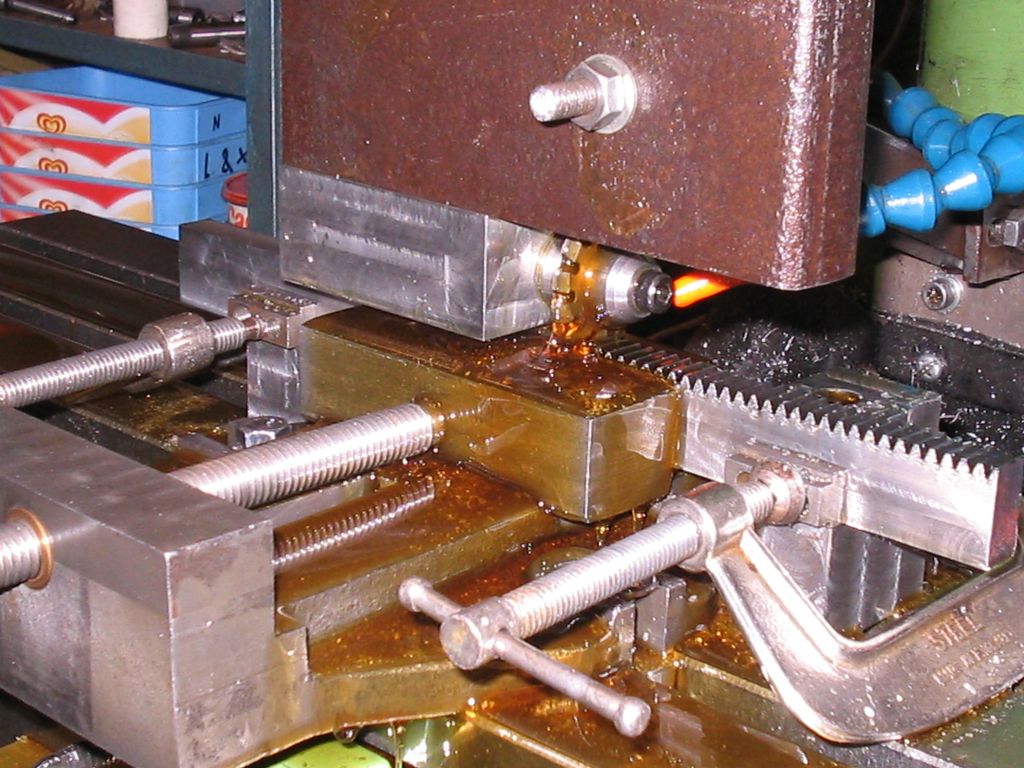

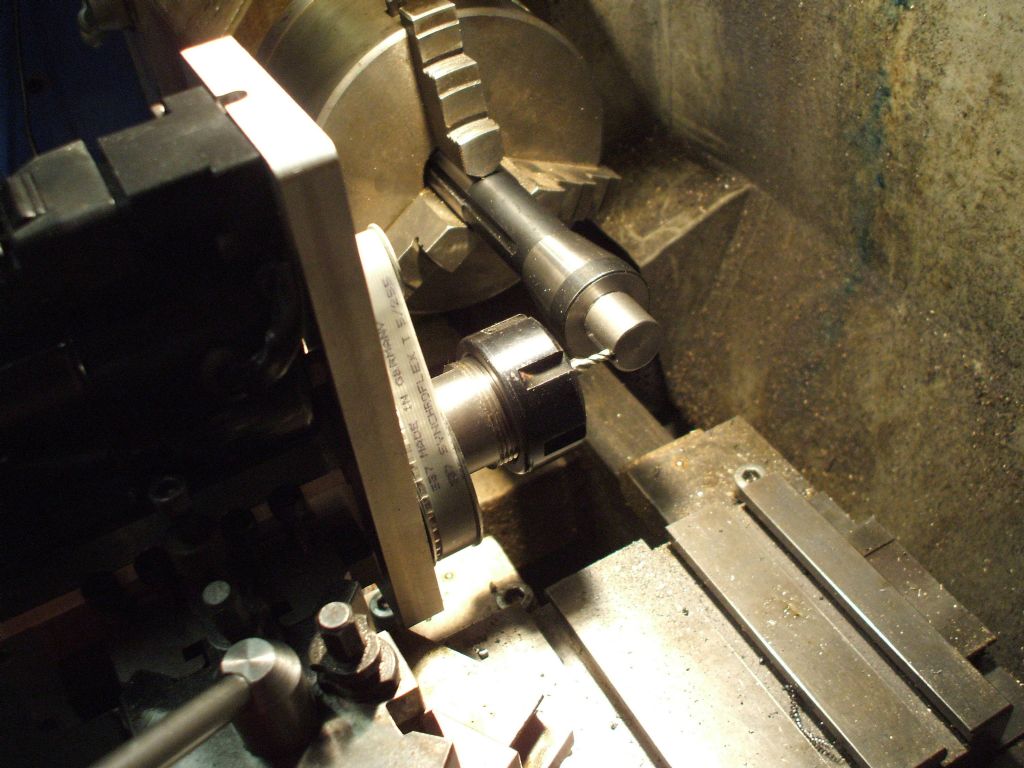

First off,I used a piece of Ali,which was to hand 63×20. This was big enough to give me a 38 t gear [1.5 mod ]. Cut it out with hacksaw/angle grinder,drilled it 12mm and mounted it on an arbor nothing fancy !then turned it to size and set it up on the mill.

Set the cutter to just brush the blank,then moved the spindle to one side while I set the dept of cut using my dial gauge. I had already been around the course to make sure that the setup was right,so I was happy enough to begin cutting. To my surprise,it went very well,no real problems,although I did feel that not all the teeth were cutting.I seem to remember that someone else remarked on this some time ago. This may be due to the cutter bore being slightly off center or the holder not being quite true.I will get a better holder for next time.

The cutting went very well and I was quite satisfied with the result [for a first effort,anyway ] Since I did not need a gear of any particular size,this was just an exercise,part of the learning curve.Since I had enough scrap Ali left over,I made a smaller gear 20t just to try it..Both worked out well,just trying to work out how to cut a slot for a key [drill and file ? ]

While looking at the range of teeth the cutters can deal with,I wondered that No1 can cut 135 to a rack ! Can you cut a rack with a mill,or am I reading this wrong ? dont really how you could move the workpiece. Perhaps not.

Again,my thanks to everyone,not forgetting Brian for the help and advice.

It has been a most satisfying experience.

,

IanT.