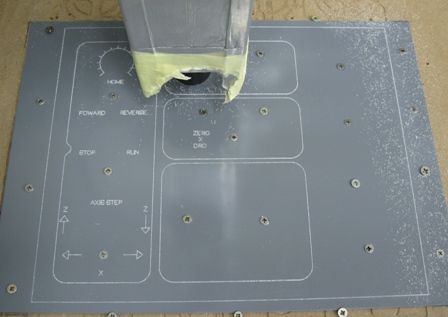

Douglas, I have made many engraved panels for equipment, my lathes, shaper, rotary table controller, etc, and lots of radio ham equipment – I use single sided ( copper on one side only)FR4 Printed Circuit Board ( fibreglass type), with the copper side pre-painted and then engraved, as this gives a nice sharp edge to the lines. I then fill with plain black boot/shoe polish! I use an old credit card as a squeegee and squeeze the wax into the lines. Wipe the panel with a clean lint free cloth and let dry for an hour or so and then a brisk rub to clean up and the job is done!

The problem with resin fillers, or any paint with a solvent based filler is that the filler tends to adhere to the painted surface so you have to clean the excess right away and that is not so easy – if the filled line/text is still wet, wiping over the line tends to drag more of the filler over the panel surface, and as that starts to dry or cure, it becomes more difficult to clean. Also, the solvent base of non wax style fillers tends to attack and dissolve the painted panel surface as well, leaving fewer choices of paint to use on the panel, ie, epoxy based paints are about the only types impervious to turpentine or thinners based fillers.

I have panels around 11 years old made in this way, and they show no deterioration at all – some are panels on radio equipment in my 4X4, panels which have endured many, many months of hot African sun!

The panels on my lathe ( an Electronic leadscrew system), shaper, etc, are similarly made and after maybe 2 years of use, with the usual oily and grubby fingers , there is no sign of filler departing the panel, etc.

Joe

Edited By Joseph Noci 1 on 10/02/2019 19:17:14

Ian S C.