Which ball turner?

Which ball turner?

- This topic has 27 replies, 15 voices, and was last updated 31 October 2020 at 17:48 by

Roderick Jenkins.

Roderick Jenkins.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- How to sharpen expanding reamer blades & how to adjust them?

- What Did You Do Today 2025

- Stuart? MTB 1M

- TurboCAD Snaps and Dimensioning?

- Clayton Steam Wagon

- First cuts with the lathe

- Fobco 10 eight drill, NVR problem

- Sieg C1 lathe autofeed and screw cutting

- Maisie lubricator

- Fitting for injector pipework

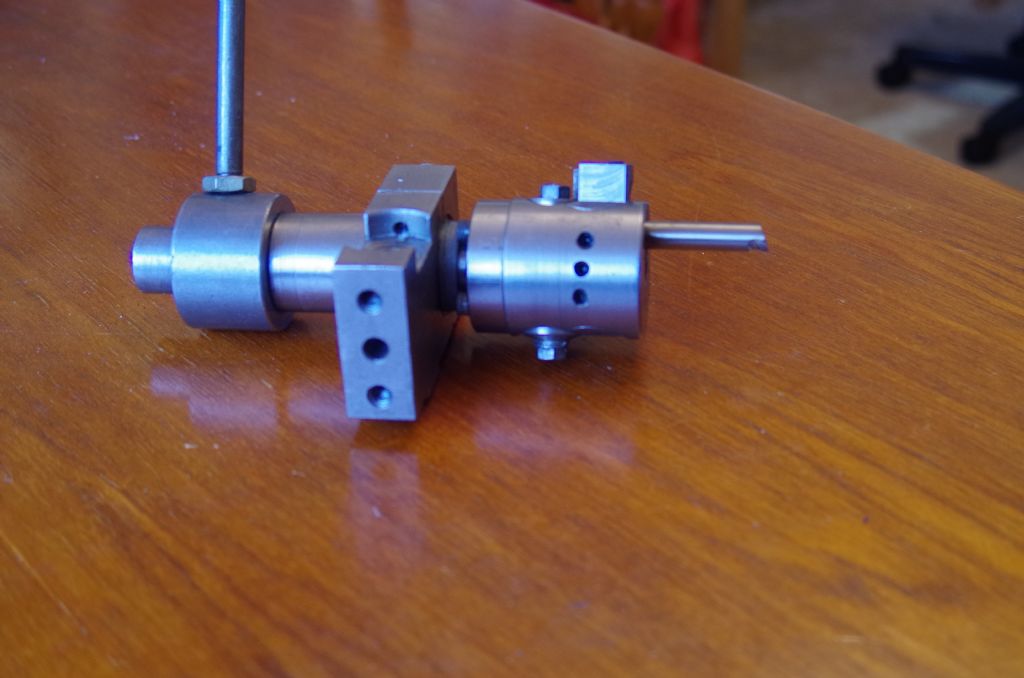

![ballturner[1].jpg ballturner[1].jpg](/wp-content/uploads/sites/4/images/member_albums/141785/879467.jpg)