One way of getting it across a lawn, or other rough surface, is to lay temporary track of hefty boards (1" thick plywood).

Difficult to advise on moving heavy unbalanced equipment because there's a certain amount of skill in it, and skills are best learned bu doing easy moves first. Worst case is a bunch of over-confident enthusiastic amateurs crushing someone under the machine. If it topples, it's natural to try and stop it: bad move – wrong! Top priority is to get out of the way! That said plenty of big machines are moved successfully, with simple equipment: rollers, levers, ropes, and a small team of fit blokes.

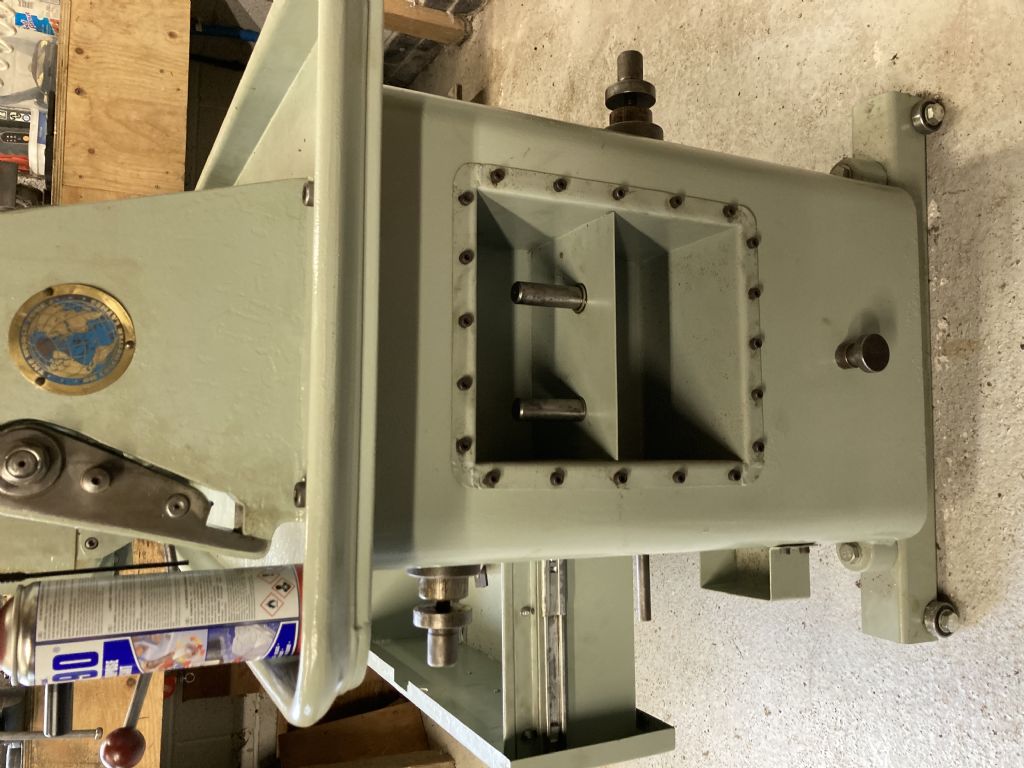

As they are taught in the Army 'Prior Preparation Prevents Piss-poor Performance'. Assemble a team and choose a leader; this shouldn't be the most gung-ho person available; be suspicious of anyone who wants the job. Drum into everyone they do what the leader says, when he says it. This is because teamwork is essential: lift together put down together. Plan the route, and rehearse it, paying special attention to awkward bits: doorways, steps, slopes, tight corners, and obstacles. How much planning depends on the geography. My workshop has a concrete garage door, accessed from a flat tarmac drive with a short ramp over the public pavement down to the road. The main danger is the tarmac, because it's surprisingly soft, otherwise rolling a big lathe would be 'easy'. My garden shed is far more difficult: steps to garden from road. Sunken path with steps to shed, or lift lathe 300mm from patio to soft lawn and then manoeuvrer machine across grass past goldfish pond and somehow swing past a tree surrounded by a low stone wall, and through a narrow shed door. Lathe in shed needs a lot more thought than lathe in garage.

Be good if you could take photos of the move and share your experiences. Interesting problem, but if it went in it can come out!

Dave

Gaz Lippid.