Norm

As the motor runs up OK when you manually operate the contactor its likely that the problem lies with the overload cut out system. As far as I'm aware Bridgeports of your era are, like my slightly earlier machine, fitted with overload cut outs which can be set for either manual or automatic operation. If set to manual you have to operate a small switch on the input side to reset the device whilst in automatic mode it self resets after a suitable interval. The selector / reset switch usually ends up close to the cabinet side and its pretty much impossible to see whether its set to automatic or manual. Automatic re-setting can become unreliable on older machines. Presumably because it sits there for years and stuff builds up so the spring or whatever that provides the re-set action isn't strong enough to bring things back into position. Mine decided tor randomly trip out and not reset for, presumably, similar reasons. Cure was a good spraying with contact cleaner lubricant accompanied by operating the manual / automatic / reset switch a few times.

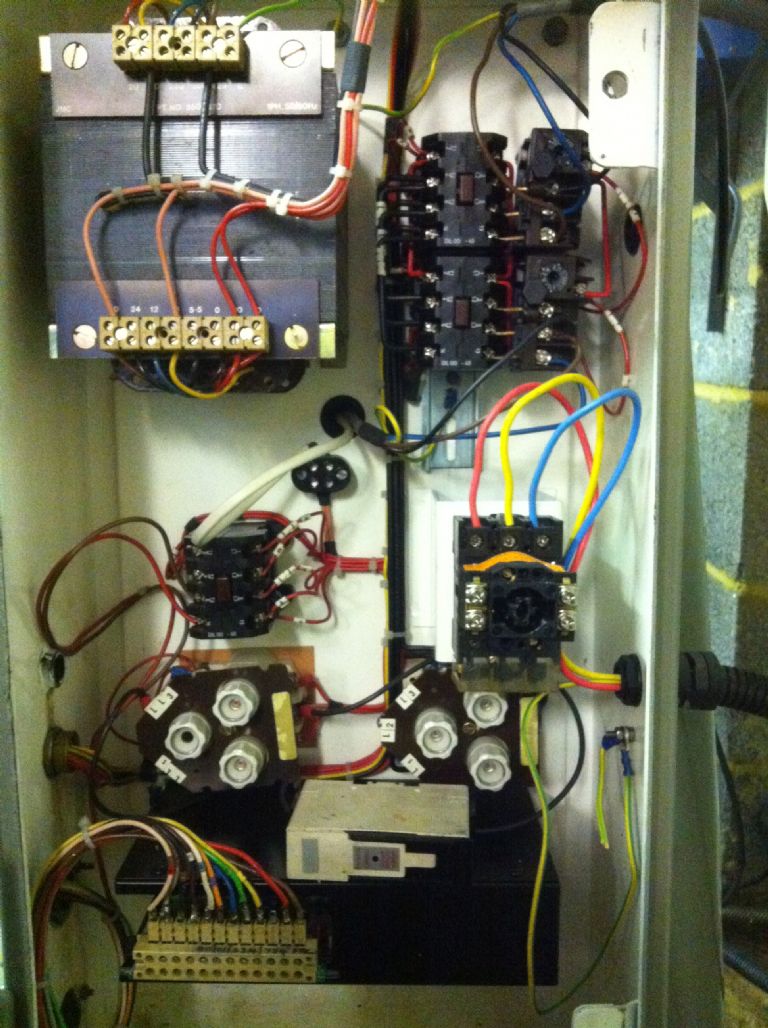

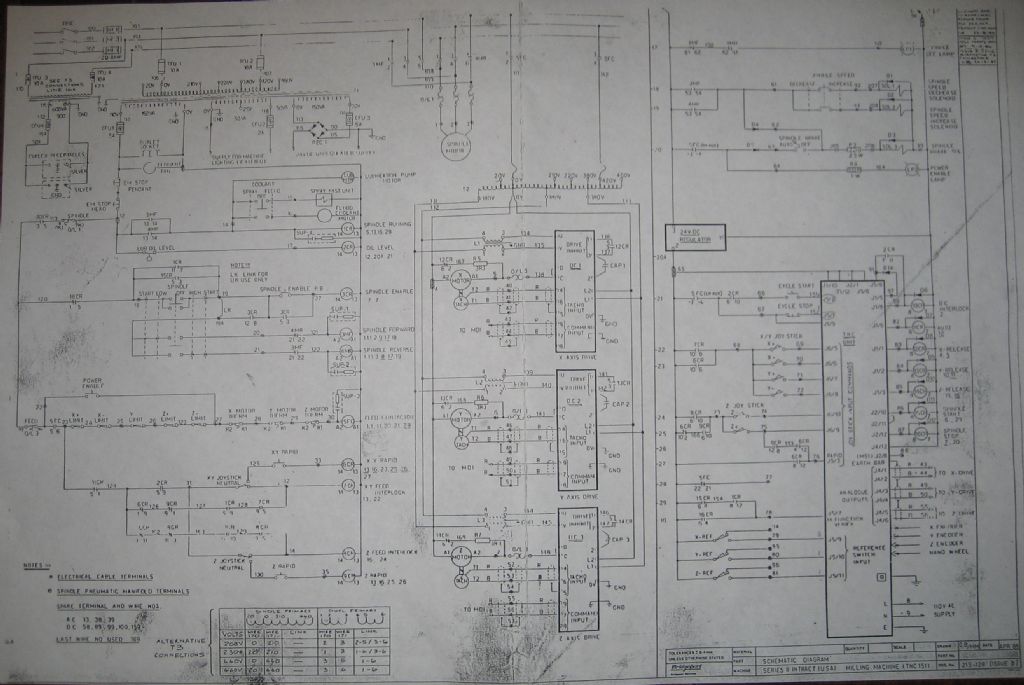

For all practical purposes wiring diagrams for machines with DC motor driven feeds, 6F / 8F, are interchangeable with the transformer, contactor and overload connections clearly shown on the left hand side. All the contactor overloads are in series so if any one has tripped and not returned nothing will work. The feed control part is always bit cramped and not exceptionally clear.

The feed and contactors all run off 110 V, usually marked LL1 and LL3 on the wiring diagram so if you switch the transformer input to 240 V everything in the electrical cabinet will work as it should.

Replacing the pancake motor isn't as easy as it seems. The output shaft is much longer than a standard motor so you need to put an accurately concentric extension on. Any error and it will vibrate like nobodies business, as my pal John found out. Mounting is bit tricky too. John butchered the front bell end of his pancake motor to make a mount and fixed the adapter plate to that. Personally I'd fork out for a quality re-build on the pancake motor if it went wrong. Its a high quality machine and almost certainly far better than anything affordable found via the usual sources. The one major weakness for home shop folk is that its not particularly happy on static converters so if its not in pretty good order a static will kill it given enough time. Probably several years in a home shop but fail it eventually will.

Static converters should really be set by equalising winding current and getting relative phase as close as possible. Not practical for most folk who must resort to getting the phase voltages as close as possible hoping the passing errors are similarly small. Unfortunately even quite small voltage errors, 10 to 20 volts, can be associated with much larger current errors to which some motors are more sensitive than others. I would never run a Bridgeport pancake motor off pure static converter. Putting an pilot, unloaded, motor in series makes them much happier.

Clive.

Edited By Clive Foster on 17/02/2016 16:26:16

Edited By Clive Foster on 17/02/2016 16:27:45

Roger Head.