My limit is about 500kg, but I suppose it depends on what the bottleneck is. Could be money, power, space, or access. In my case, it's space, unless I spend big money and move house. As it is, I have to fit my whole workshop plus other bits and pieces into a bit less than the size of a single-garage. (Tiny British garage, not one of those lovely giant American things!) There's not quite enough headroom for a Bridgeport. Quite a few advantages – easy to keep warm, and I didn't have to upgrade the power apart from the lighting because the machines are all modest. But it's at least 50% smaller than I'd like.

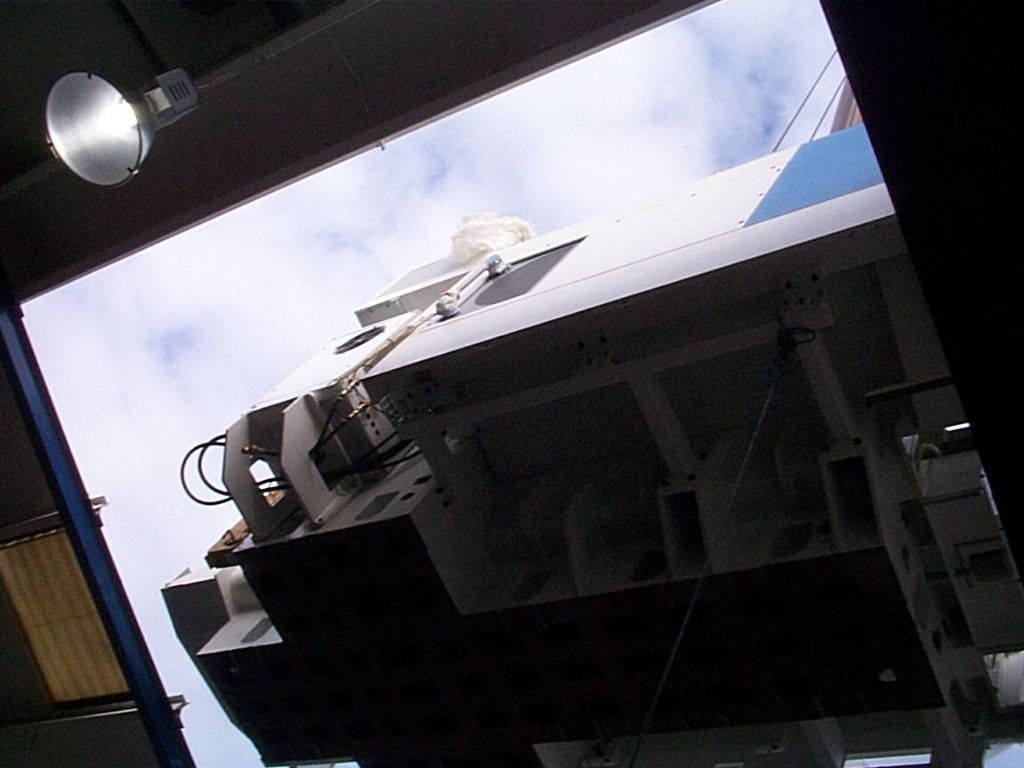

More a private museum than a workshop, but the largest I've seen belonged to the retired owner of a building company. He collected big ex-industrial lathes, at least 20 of them. I remember looking at a DSG with a chuck big enough to spin a Myford Super 7 and wondering how on earth the chuck was changed without a crane, which he didn't seem to have! The building covered an area about the size of two tennis courts and was purpose built with interlocking concrete piles, with a mezzanine floor, a large industrial door, and corridor space for a big fork-lift. Power from a substation under a pylon, which I guess fed the rest of the site, which seemed to be making large pre-cast concrete panels, pillars and other hefty stuff. Secure fenced site, with access and turning for the biggest trailer lorries.

Although the building was industrial, I guess it would cost a couple of million to buy new. In fact, much cheaper because the piling was surplus, he owned the land and the equipment needed to erect it, and could divert employees to work on it whenever business was slack. Most of the lathes were picked up gratis from his trade contacts. Although they all had power, as far as I could see only one machine was actually being used.

At the time I owned a mini-lathe…

Dave

Edited By SillyOldDuffer on 16/09/2022 19:53:14

HOWARDT.