Thanks for all the comments, on with the build.

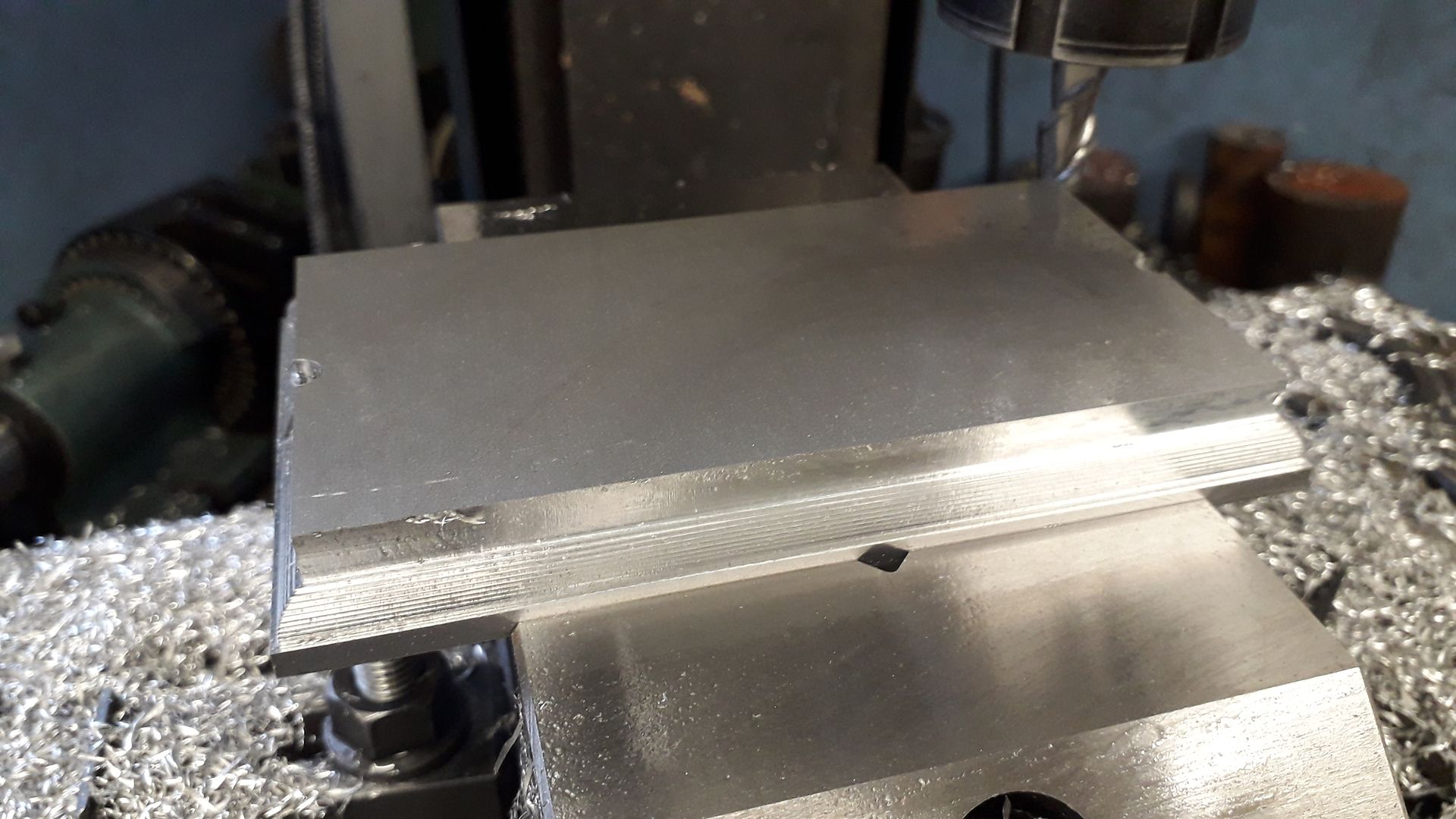

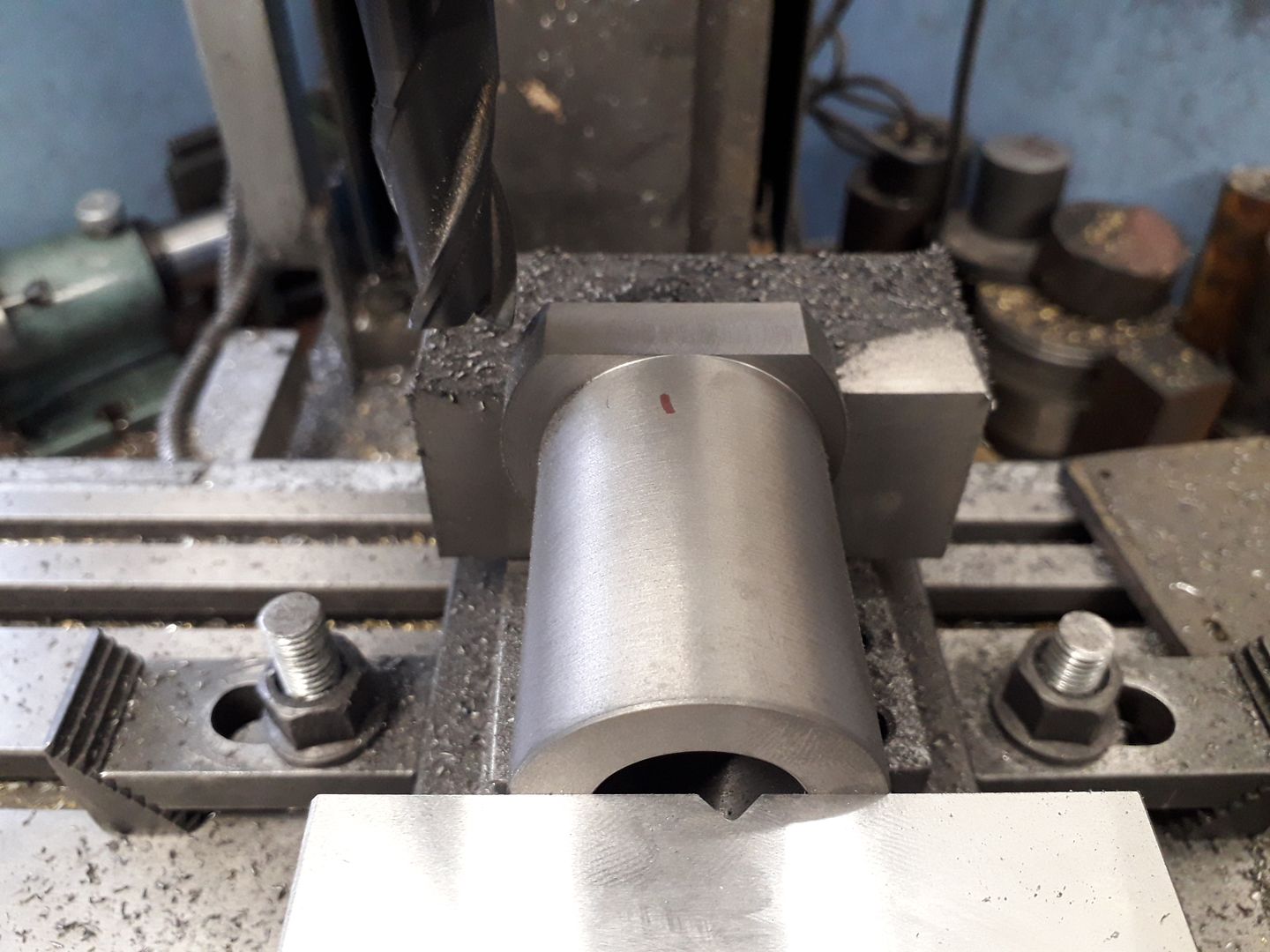

The base plate was bandsawn from some 16mm 6082 plate and the two long edges flycut to size. Then with the plate held horizontally in the vice the two ends were squared up.

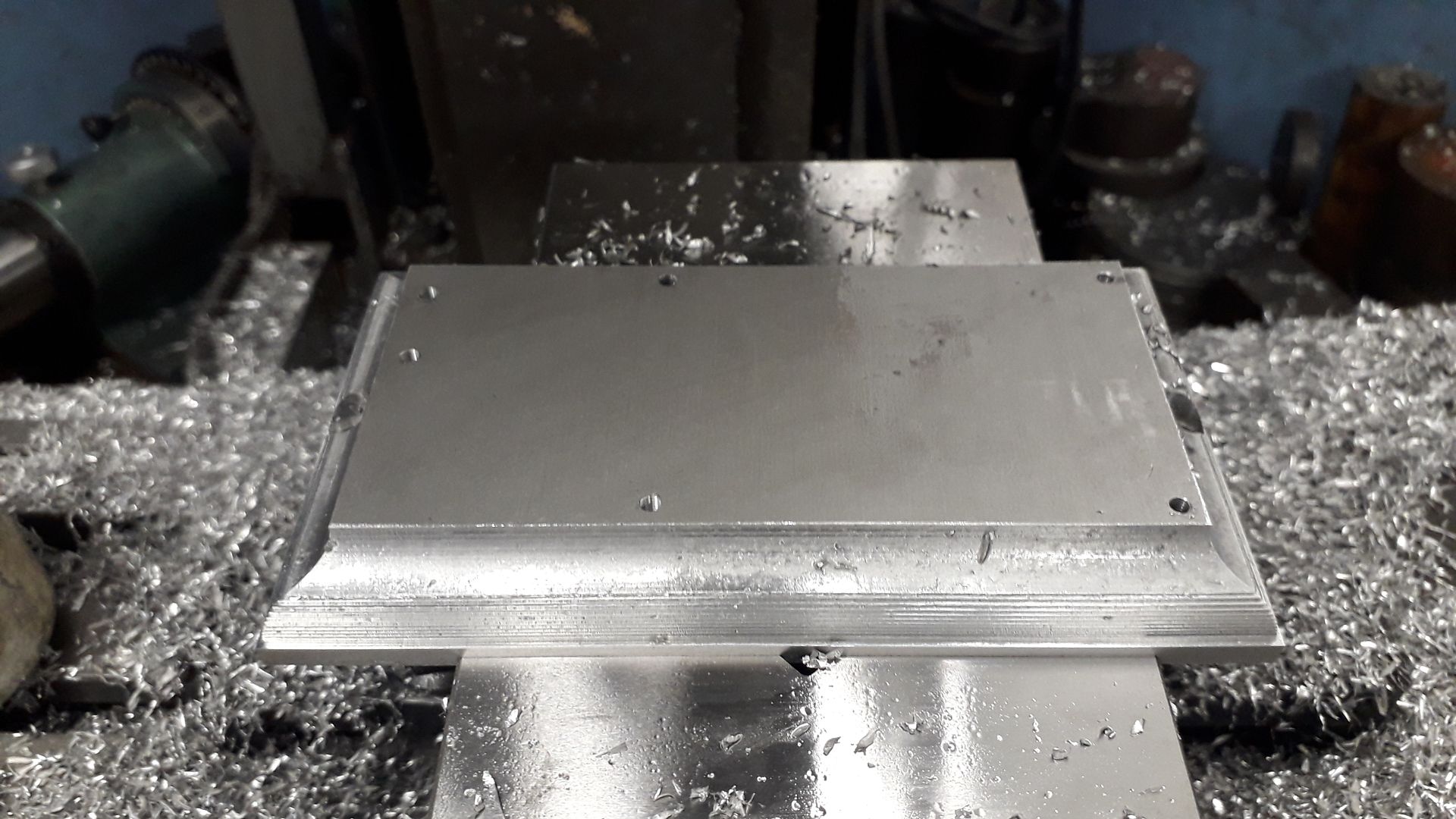

Then a full 12mm height x 1mm deep pass all around formed the rebate, I used a 2-flute aluminium specific cutter which gave a nice finish.

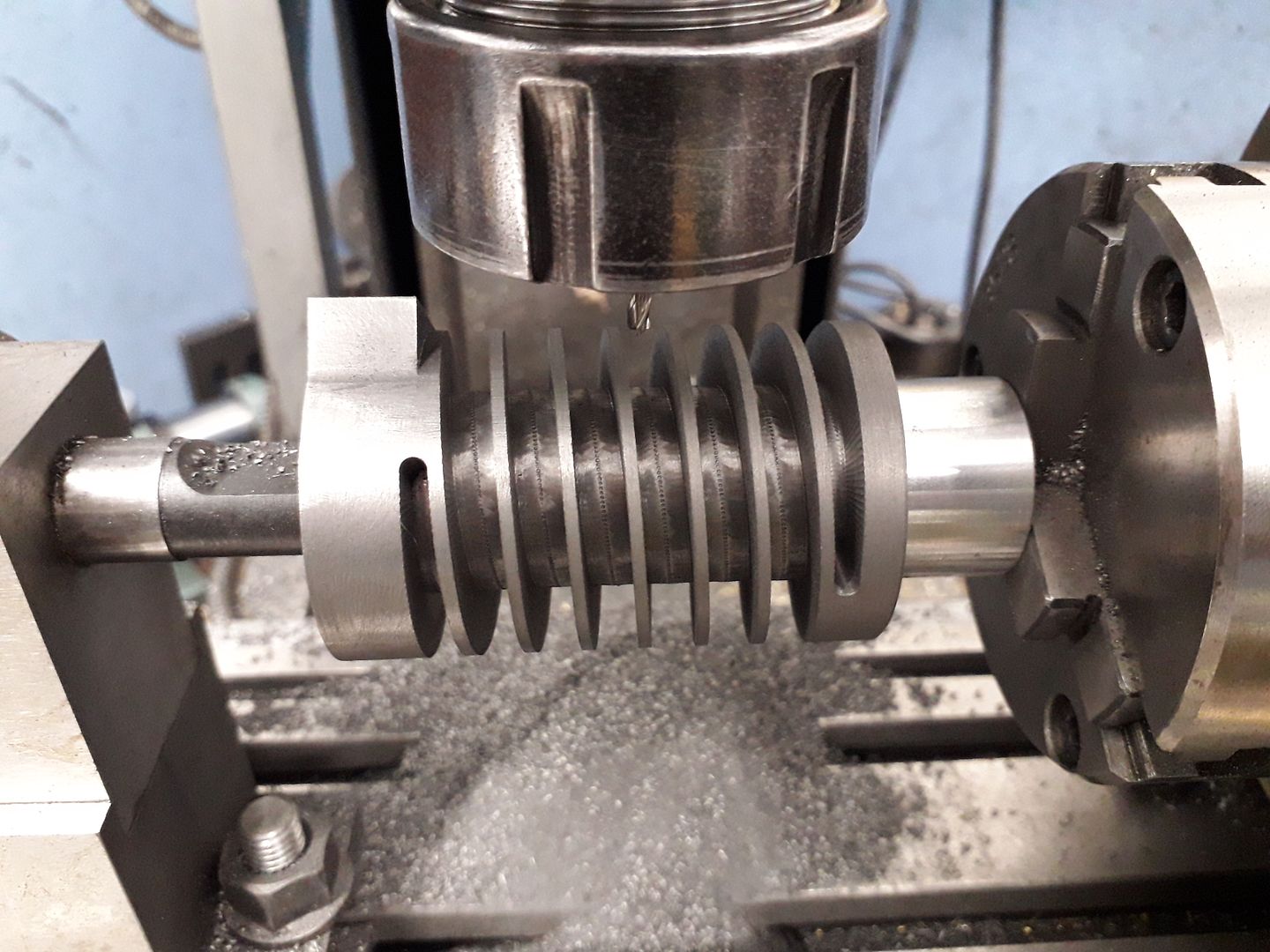

Then using a set of co-ordinates taken from my Alibre drawing the convex part of the ogee moulding was cut in 0.5mm vertical increments around the four straight edges

Luckily I had a ball nose cutter which meant that the concave part of the moulding was a lot quicker to cut.

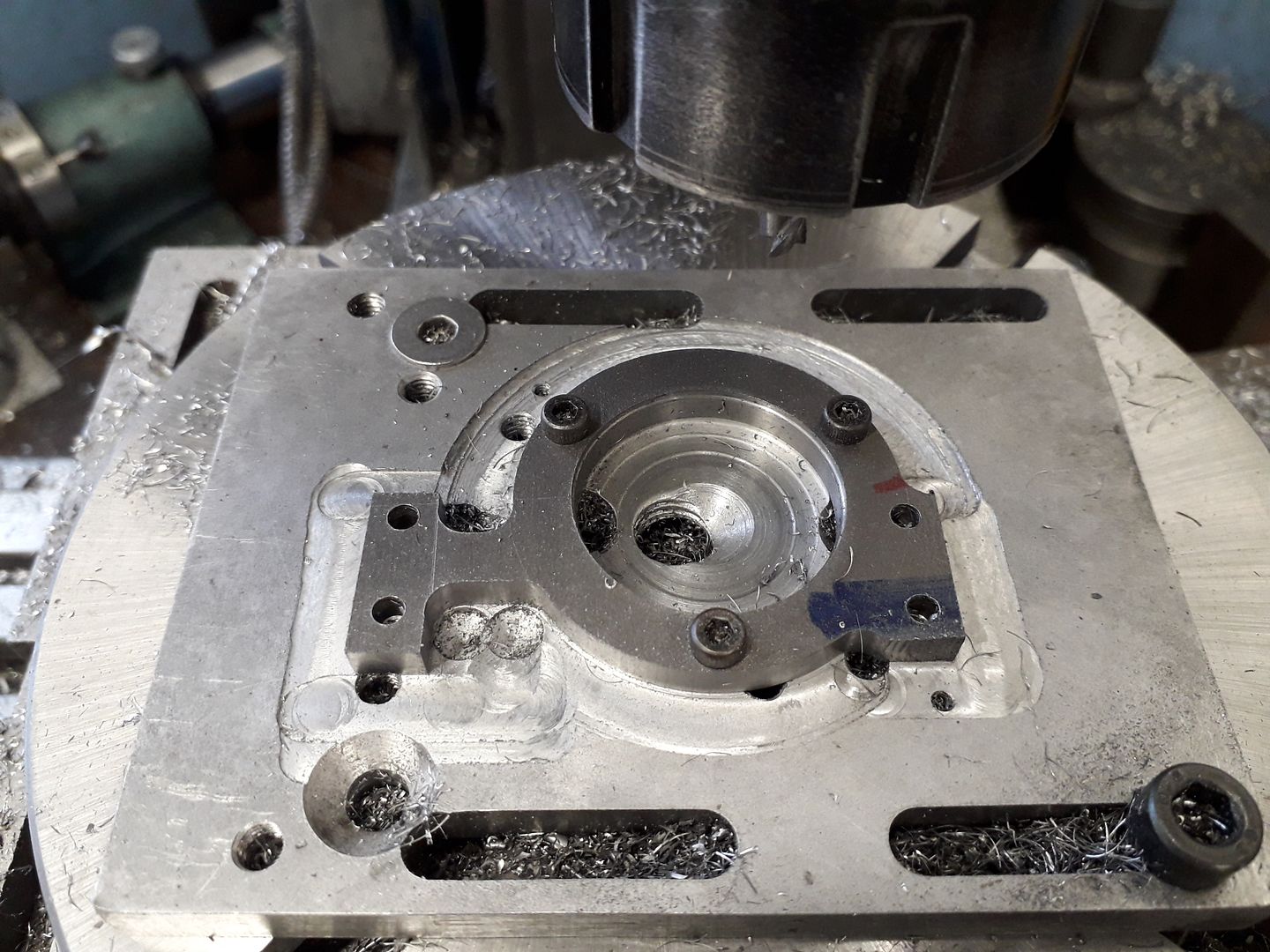

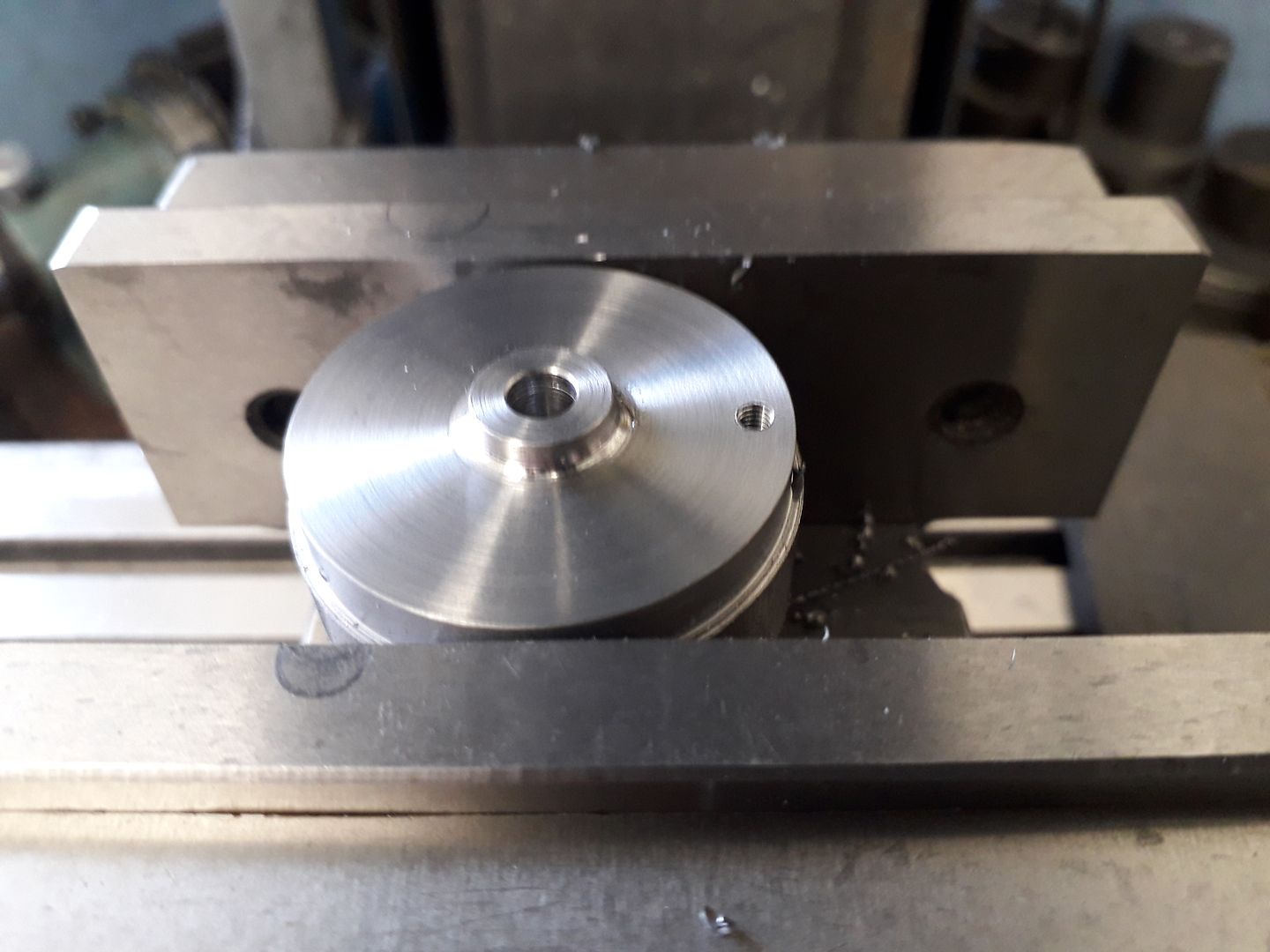

While still in the vice the various holes were drilled and tapped, the smaller blind holes with a spiral flute tap and the M8x1 through hole with a spiral flute which just pushed the long spirals of swarf out the bottom of the hole and no need to keep backing off the tap to break the chips.

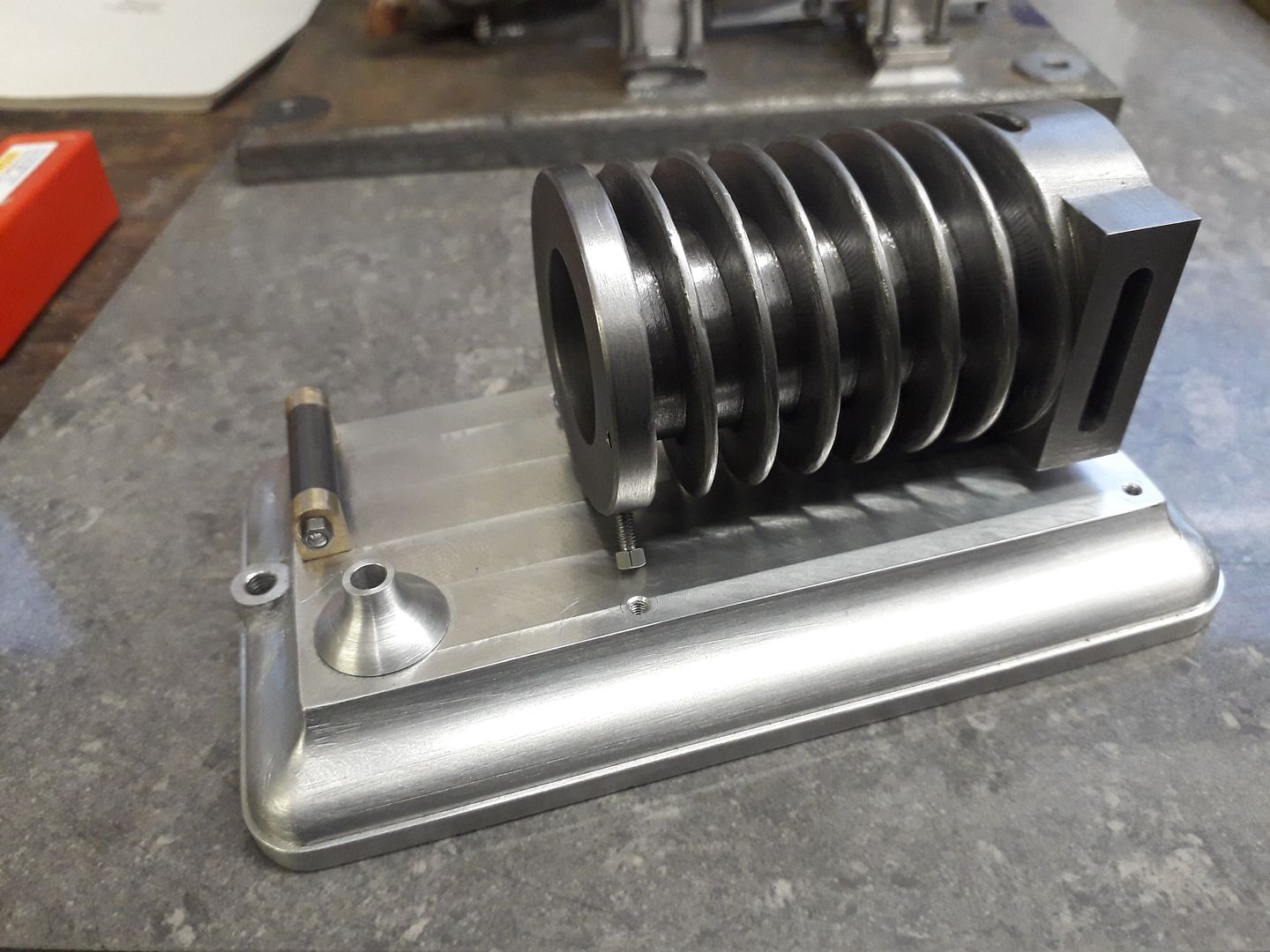

The base was then transferred to the rotary table to round and mould the corners, I decided to do every other cut on these.

It was then just a case of blending the stepped cuts into a nice flowing shape with files followed by some Emery cloth.

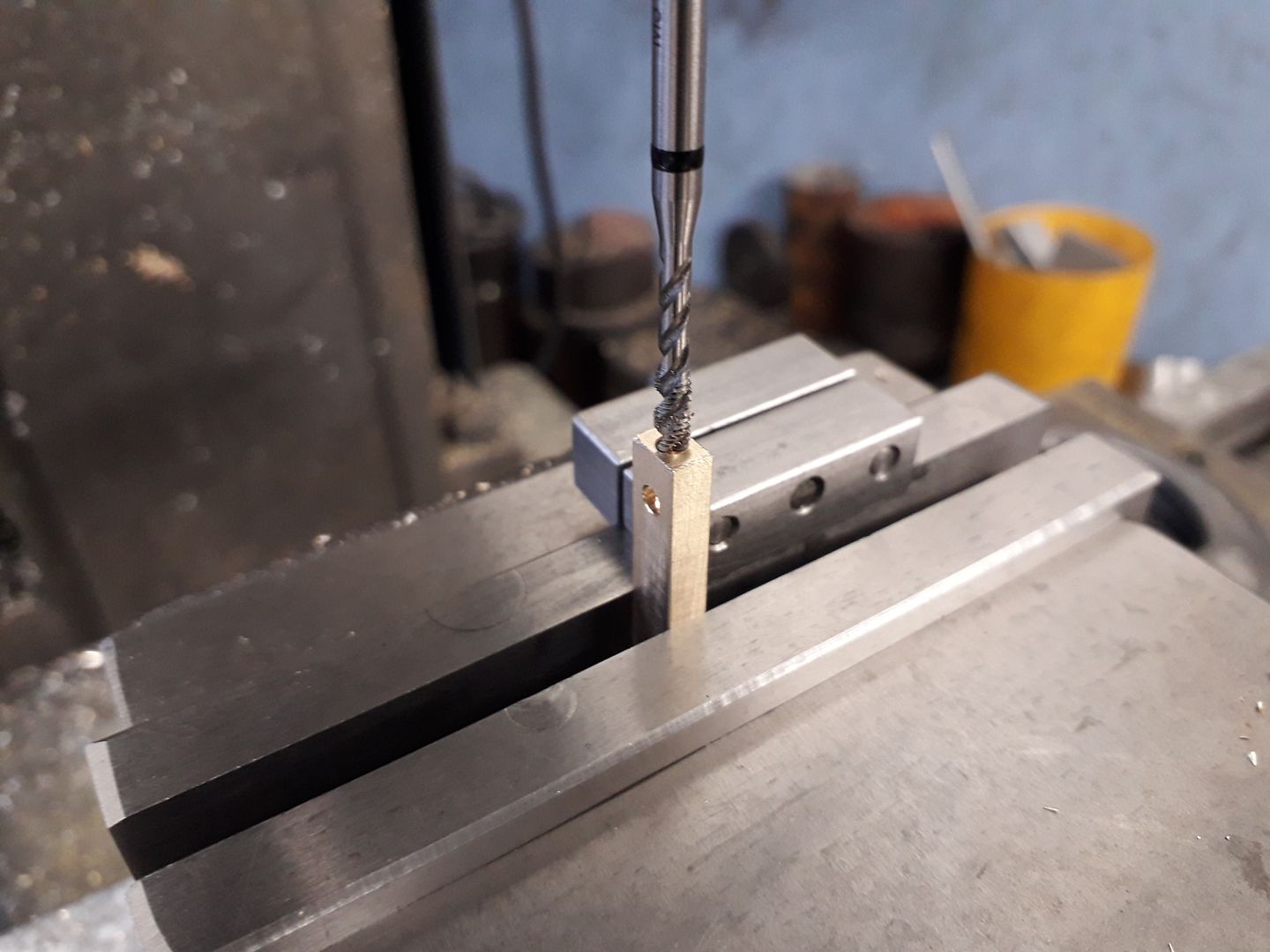

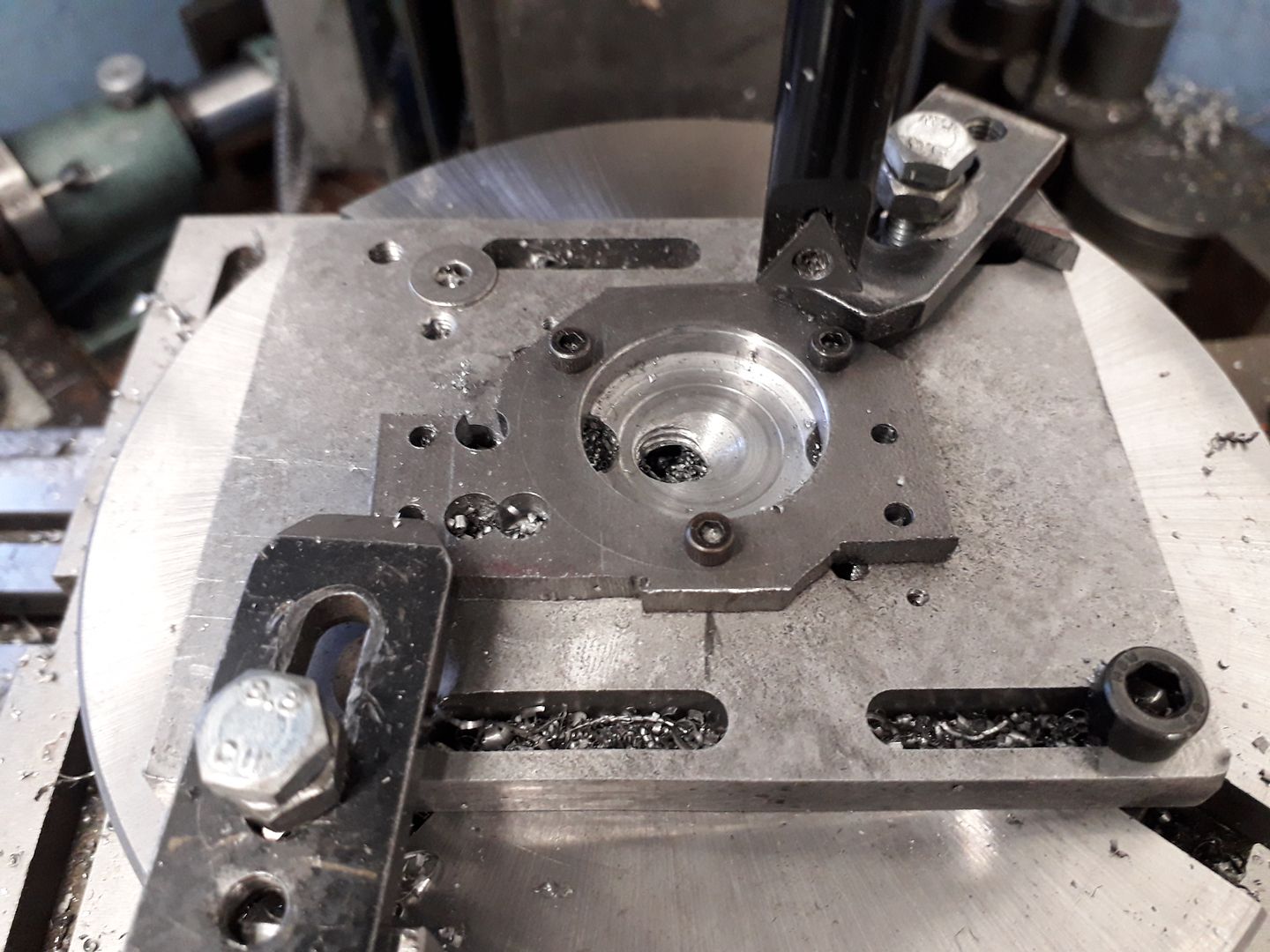

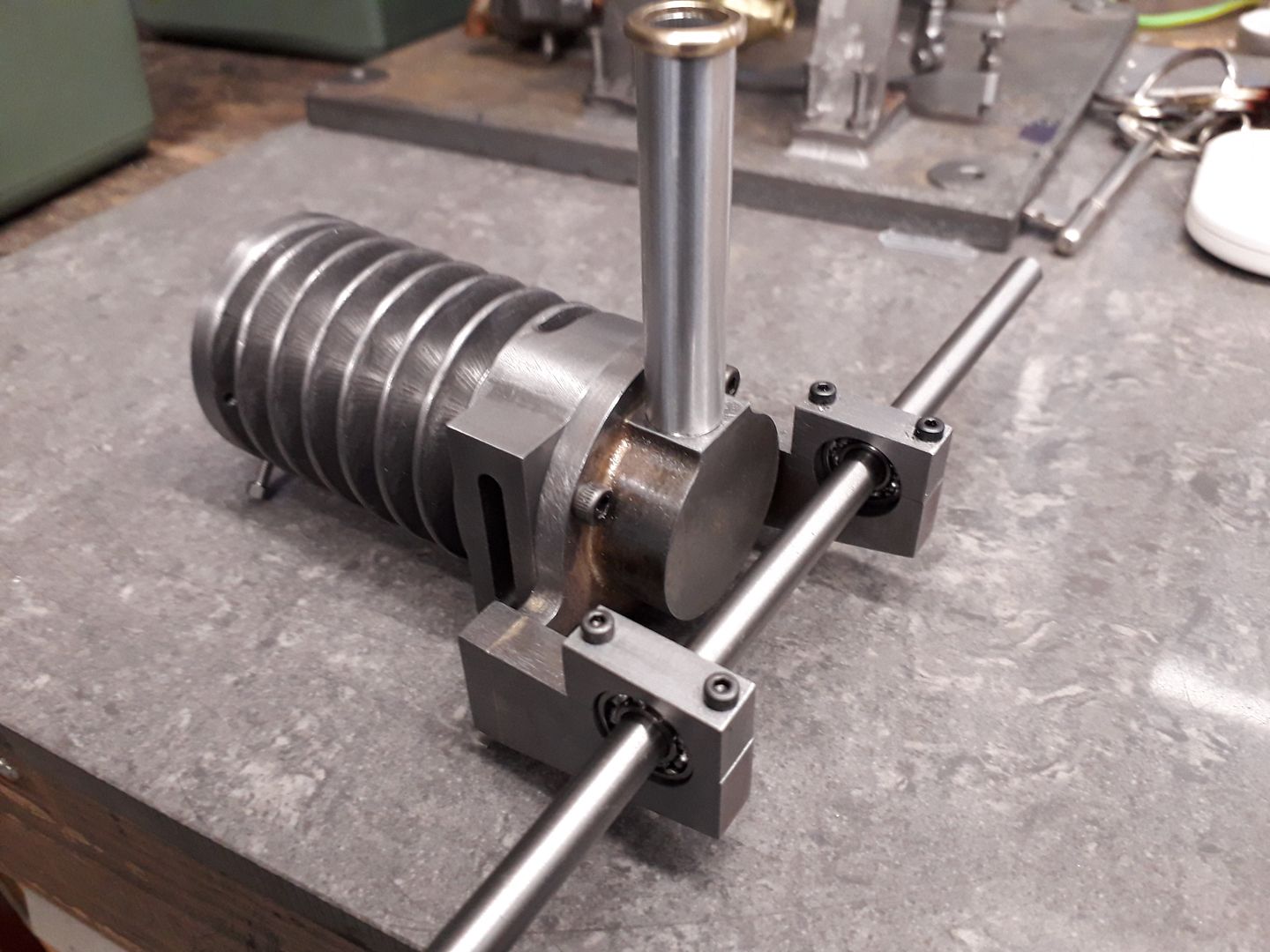

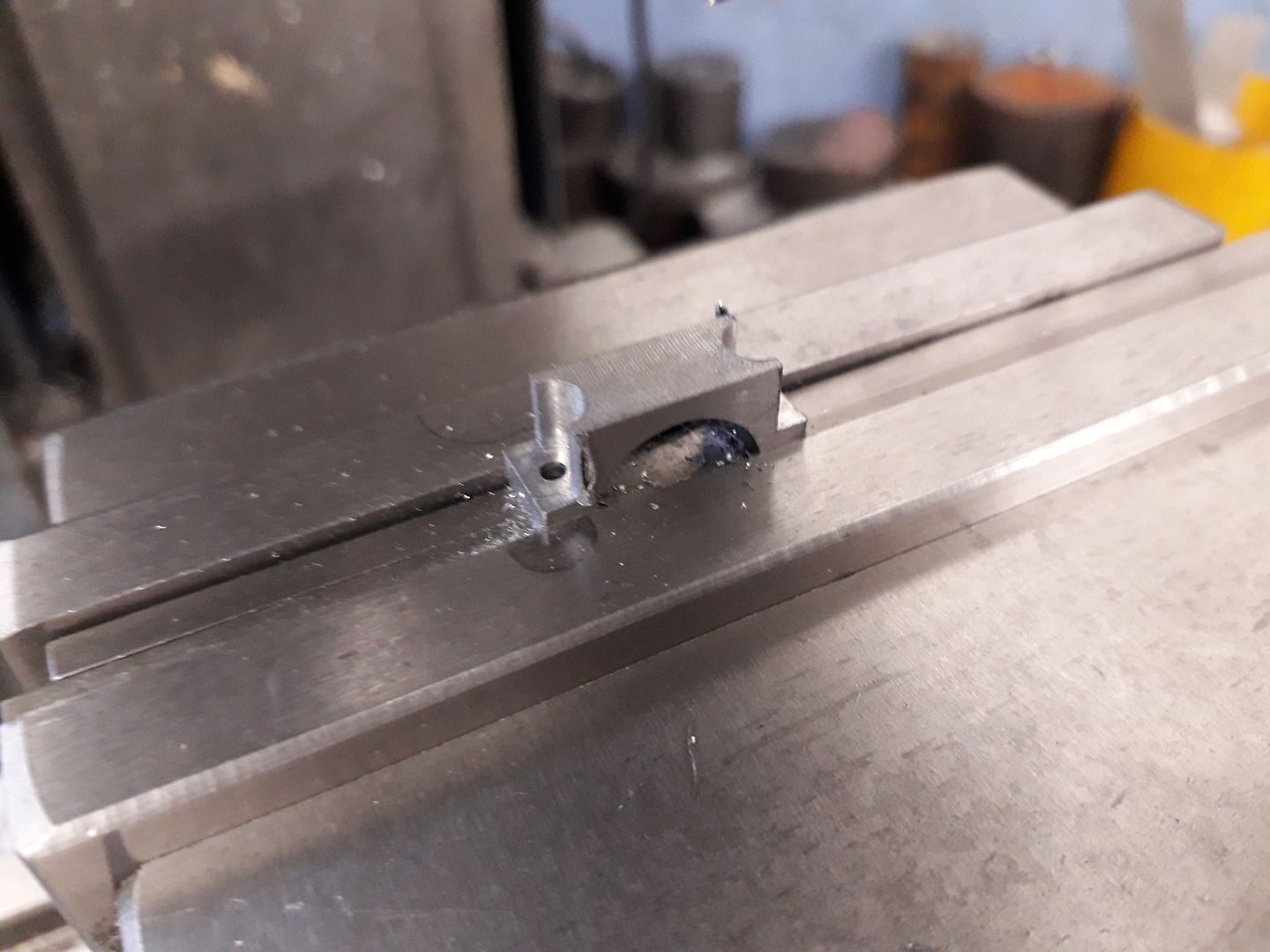

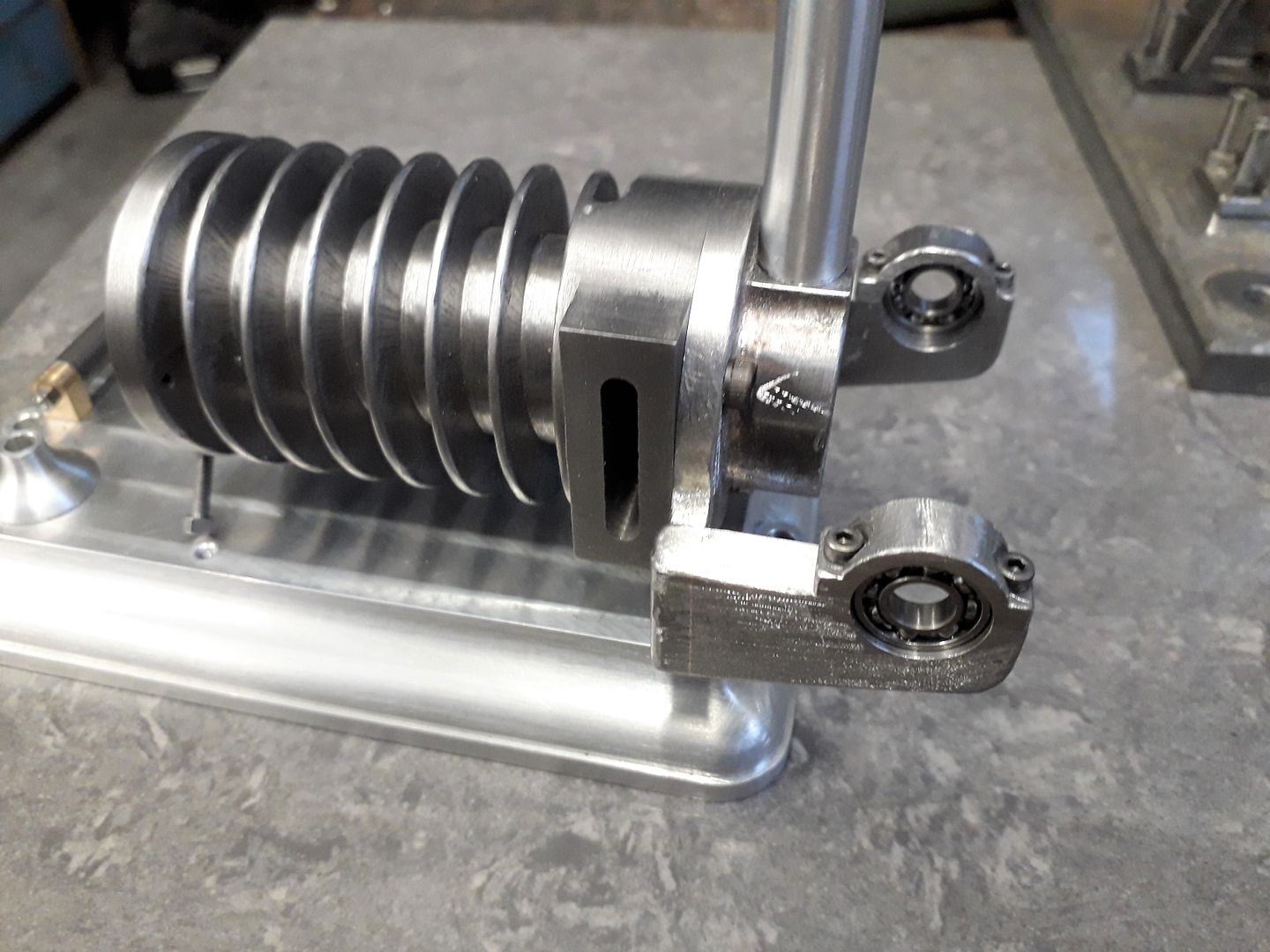

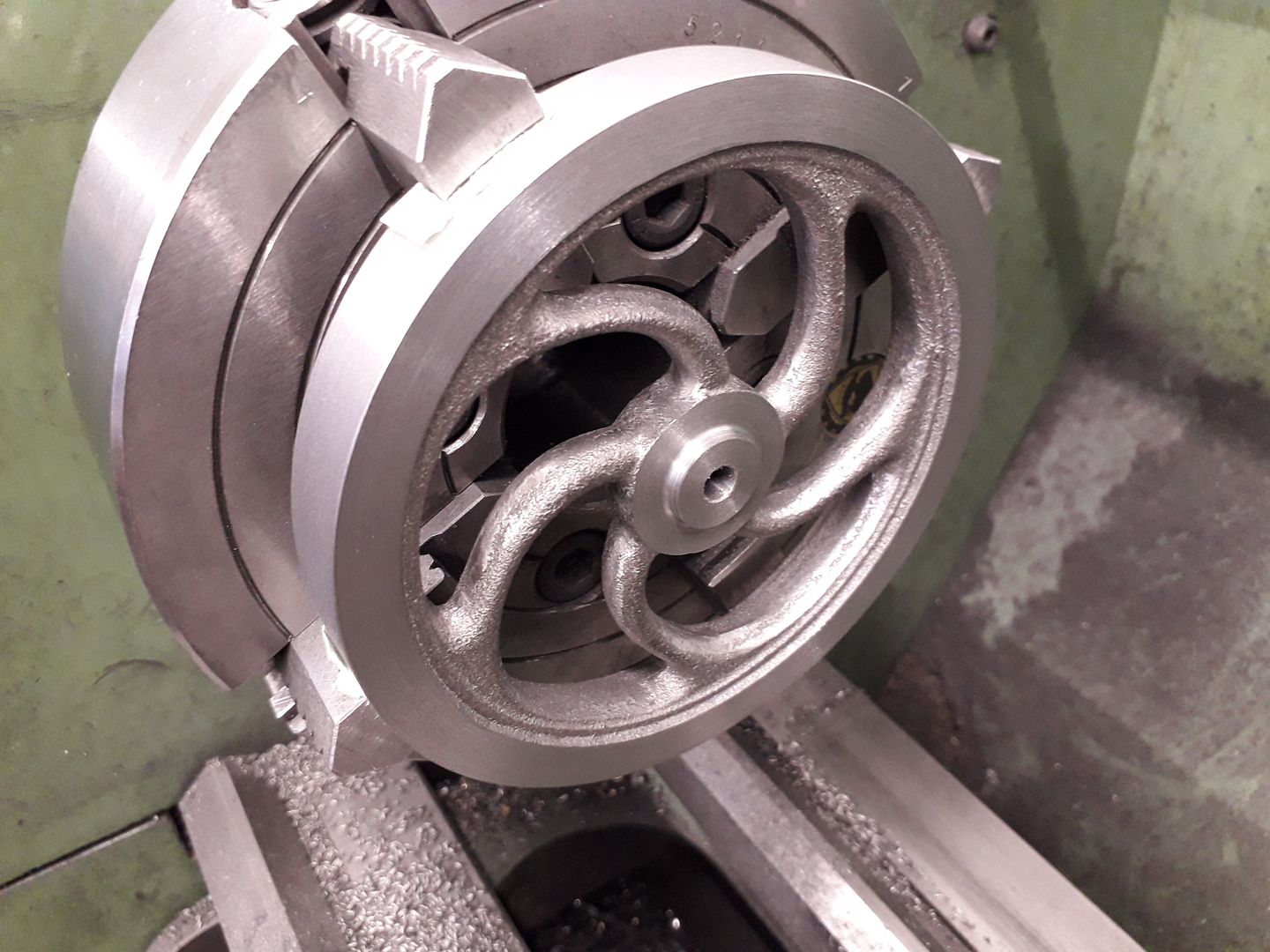

The two lugs for the Evans beam to pivot on were worked onto either end of a small length of brass.

Then sawn off and rounded over, again on the rotary table.

JasonB.

JasonB.