Posted by Terry Kirkup on 02/03/2021 20:57:29:

I'm only here because I'm researching everything about the WM18 mill for myself, but on reading all this I can't resist asking –

NDIY, just curiosity but is the VFD on your Raglan lathe a "chinese offerings. Poor design – cheapness?" type or Vorsprung Durch Technik? (or even a 50 year old Western thing?).

Terry,

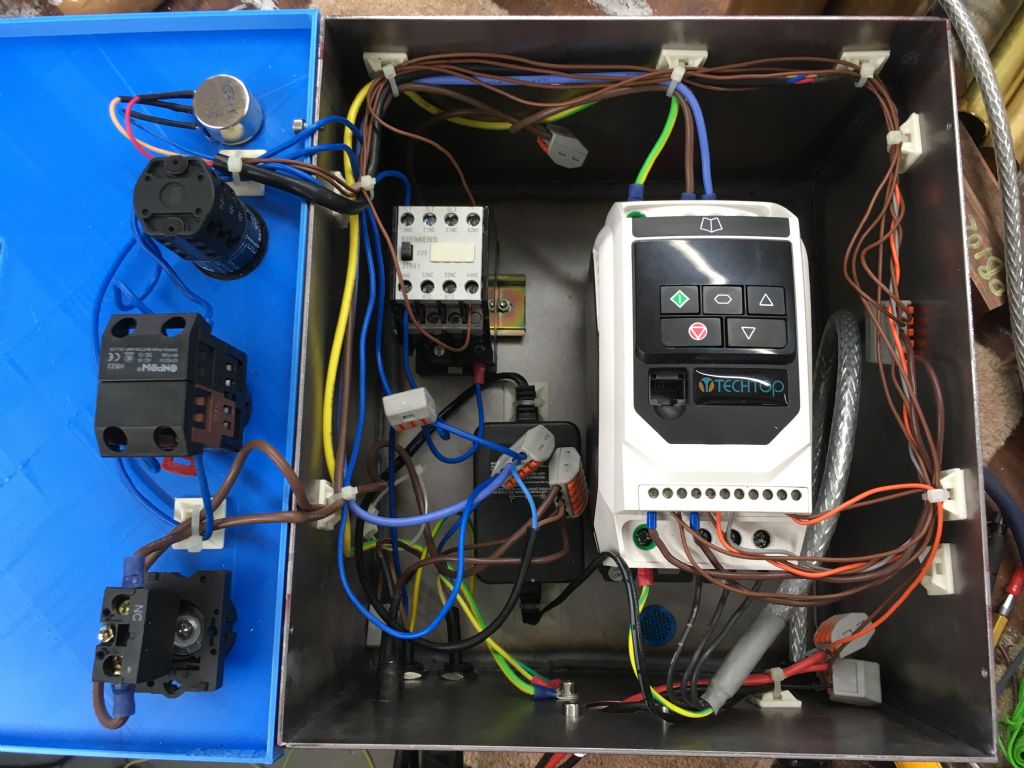

I’ve no idea. It is tucked away in a box and was already fitted when I bought the lathe. I have seen it but can’t remember the make/model. Likely was rather more expensive than the present models – prices have reduced greatly for cheaper chinese offerings. I think it is rated for one horse power but cannot be sure about that.

Why do you say “ Poor design – cheapness?" The material I drilled was Aluminium (the OP could have been cutting anything, as he didn’t treat us to any great detail), the drill was sharp, the lathe was slowed, but not by so much electronically as the mechanical variable speed control will reduce to under 300rpm (at full motor power, of course) and the material was, as I stated, Aluminium.

At the time, my initial post was of surprise (well, not really) and compared a well constructed hobby lathe, built at least 50 years ago in the UK. Martin W attempted to argue that the modern chinese kit was (perfectly?) OK and my further posts were put up to defend my ‘old British iron’ – it being far more capable than the cheap chinese supplied modern kit, without recourse to giving the chinese kit ‘an easy time’.

My one horsepower induction motor may possibly not have coped with going from 6mm to 22mm in steel without over-loading, but I am confident it would not have destroyed the motor/drive electronics, making it a very costly operator error. Half the trouble is that the modern machine manufacturers over-hype their machines by making claims which might only be achieved in ideal conditions.

I wonder if there is any directive within the operator manual to provide the user with guidelines re run times at reduced speed? Somehow I doubt it but am open to being informed otherwise.

I am sufficiently savvy to know that these DC motors need to be (severely?) de-rated at slow speed (and not to exceed the maximum capacity, as the operator likely did!). I maintain that my lower-rated induction motor is a far better proposition than the ‘pseudo claimed’ (for the less-savvy) 1 1/2 HP arrangement in that particular chinese machine.

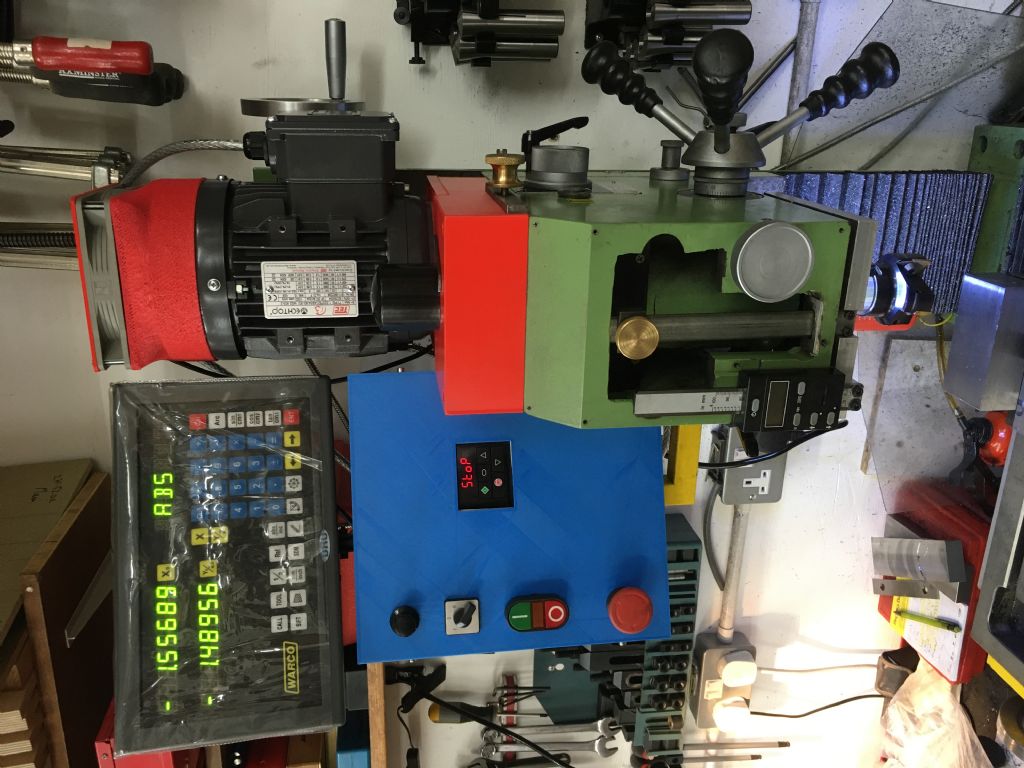

I am confident that both my Centec mill and my Raglan lathe would cope with more arduous tasks – at those slower spindle speeds – because both are rated more ‘honestly’ and have drives which are more suitably adjusted with regard to power output at those lower rpm’s. 270 rpm and 85rpm were the minimum speeds quoted, for full power operation, when both my lathe and mill, respectively, were built.

Nick Webb 1.