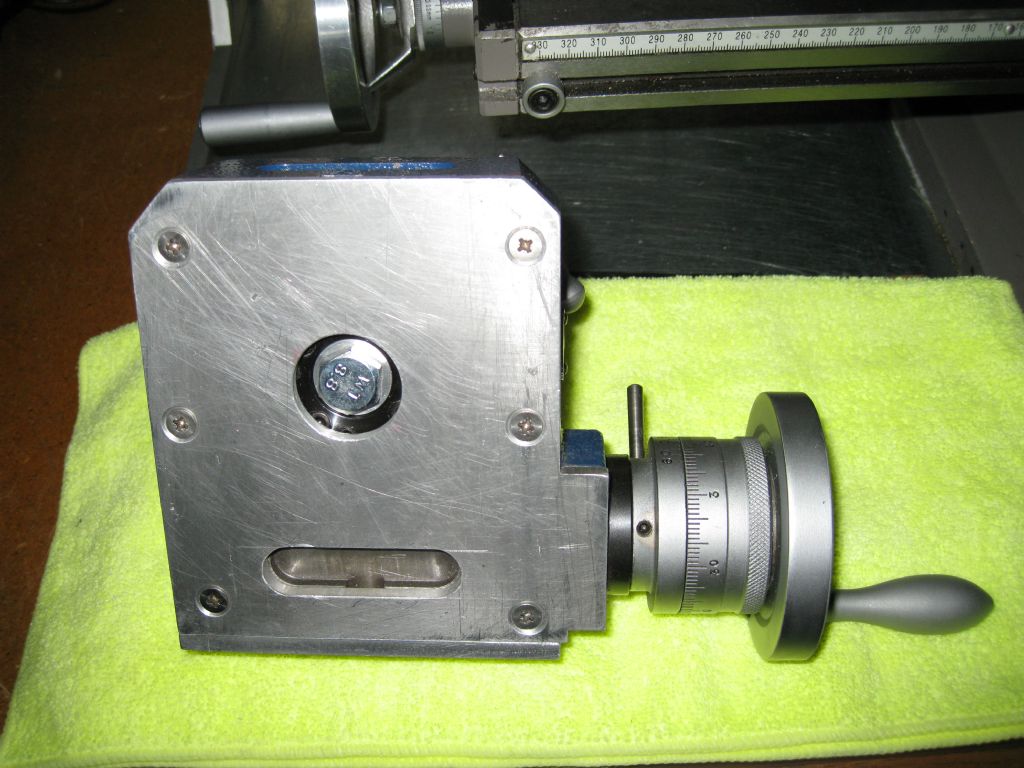

My R T is a Vertex HV6.

The slots for mounting bolts had to be extended to allow it to align with the tailstock when mounted on my Mill/Drill. It is aligned using a Square against the back edge of the table, and clamped down, using short studs fixed into Tee nuts..

Most often used vertical rather than horizontal. (i.e with the axis horizontal)

The clamps operate on the table rim, so it does not go off centre, and it appears to be reliable.

(I have used it several times for gear cutting, with dividing plates, without any obvious problems)

A 2MT/Myford adaptor allows larger work to be carried, and machined (eccentricically, if need be, using a small 4 jaw Chuck).

If it will fit onto your machine, my advice would be to buy one.

Like so many tools, once you have it, many more uses will present themselves.

Howard

Howard Lewis.