Good example of how following safety rules and regulations actually makes things more dangerous due to the inherent confusion. Can't say that I approve of the latching type E-Stop switches as they effectively act as a disconnector once latched and appear to remove power from the machine. Bad on two counts:-

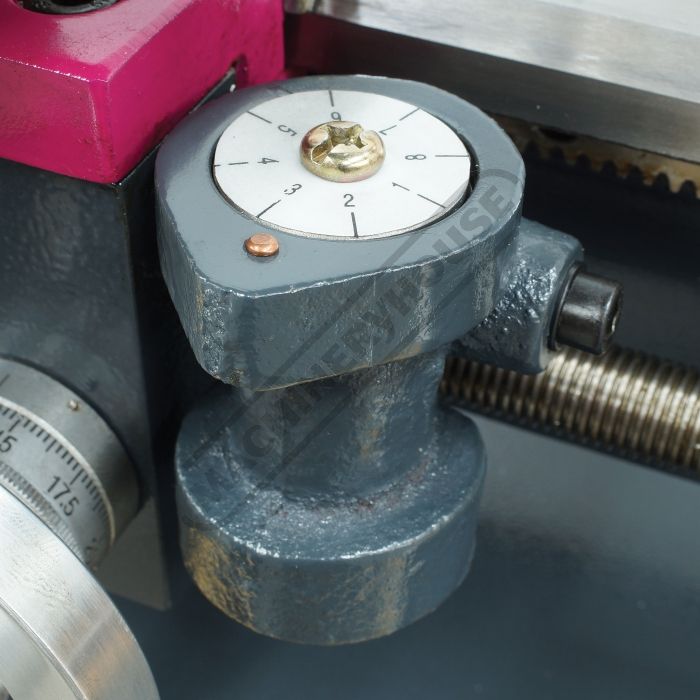

Firstly there is no clear indication that the switch has latched and is off. In the latched position the button is typically around 1/8" or few mm lower than normal. Not something easily noticed during the usual faff around working towards panic "Why won't the poxy thing go." situation.

Secondly without detail information on the circuits you cannot be sure where the power break of a latched E-Stop switch actually is so its quite possible for hurried folk to diagnose power loss due to internal problems and start investigating with power still on. Yes I know you should make sure everything is off before digging in but flustered folk can, and do, make silly mistakes doing things which normally they would know not to attempt. Even skilled help bought in to do the job can do silly things it not given all the information on the basis of wrong ASSumptions. Both places I've been in somewhat different situations. Regulations say that microswitches should be included to interrupt power if panels are opened but such things are regularly disconnected or otherwise circumvented by folk who just want to get on with the job.

The red stop button cap on the NVR switch raises the concept of kludge a little further towards an art form.

The rule framers seem to think you can inconvience people into being (theoretically) safe. A dubious proposition if ever I saw one. Unless the intention is to make folk think that using a lathe (or whatever) is just too much trouble.

Hard to beat the set-up on my Smart & Brown 1024 VSL. Proper disconnector on the main power feed. Big red lever on yellow background so On – Off status is visible from right down the other end of the workshop over 20 feet away. Machine has NVR relays on all controls with shrouded pushbuttons to select forward or reverse drive and a big red mushroom headed non latching stop button. Stop button is over 2 inches diameter and falls easily to hand. Simple, straightforward and sufficient. Each control does one thing in exactly the manner you expect.

Clive.

Michael Gilligan.

Michael Gilligan.