Un filter perdu, a boiler still not yet mounted, and lights confirmed…

'

A somewhat lazy day but I cleaned the inside of the car, a wheelchair-converted Renault Kangoo, and finally replaced its broken mirror – I've booked the MoT for Wednesday. (I'd struck the mirror on an overhanging hedge-branch, losing half the glass; but enough remained, held in with lots of duct tape, to be useable.)

I remembered an "advisory" from last year (year before?) about changing or cleaning the pollen filter I never knew it had. It's not called that in the Owner's handbook, which does include things my version does not have, but of course neither is its location given!

The Internet yielded only fair to poor videos of changing the filter on the new Renault Kangoo. Still, they gave a clue as to where it might be.

Thinking about it, the ventilation system could well be clogged because it emits far more noise than hot or cold air; and in some conditions demisting necessitates using a squeegee every few minutes. This though is a modern (ish) car, so Goodness only knows where they've hidden any of the system. As a neighbour put it, it would have been designed by people who came straight from university and had never serviced a car in their lives!

'

Tidied up, locked up, had tea and as relief from being baffled by what should be easy to find and service out on a vehicle, turned to my steam-wagon. I'm still trying to mount the boiler in the chassis, and this being a vehicle…

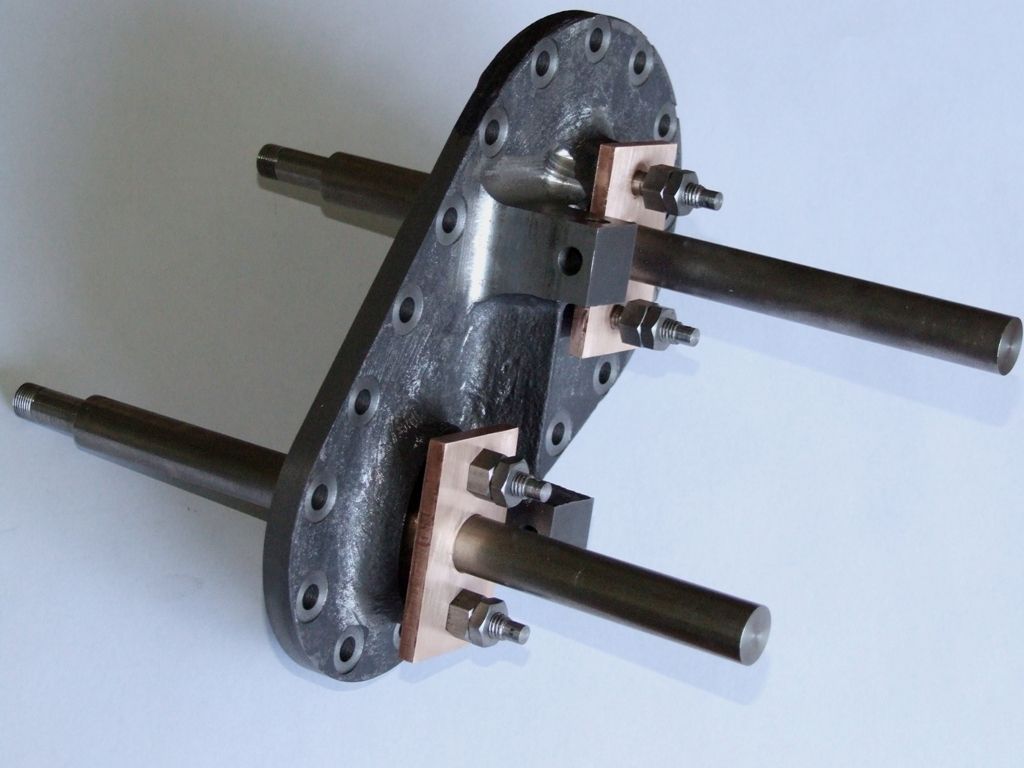

The boiler is an odd shape, and has three rather thin-looking lugs on the vertical-cylindrical firebox of diameter is over 4 inches smaller than the distance between the chassis rails which are not parallel at that point.

Also the smoke-box is not fastened to the boiler, as is typical on a traction-engine, but separate, as on a locomotive; and has to be drawn forwards to allow removing or installing the boiler in the frame.

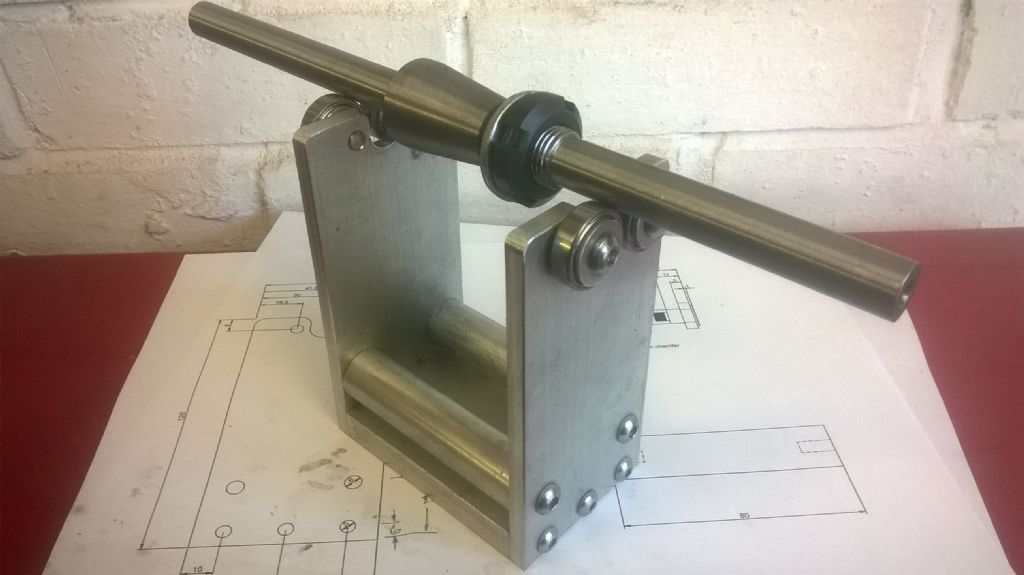

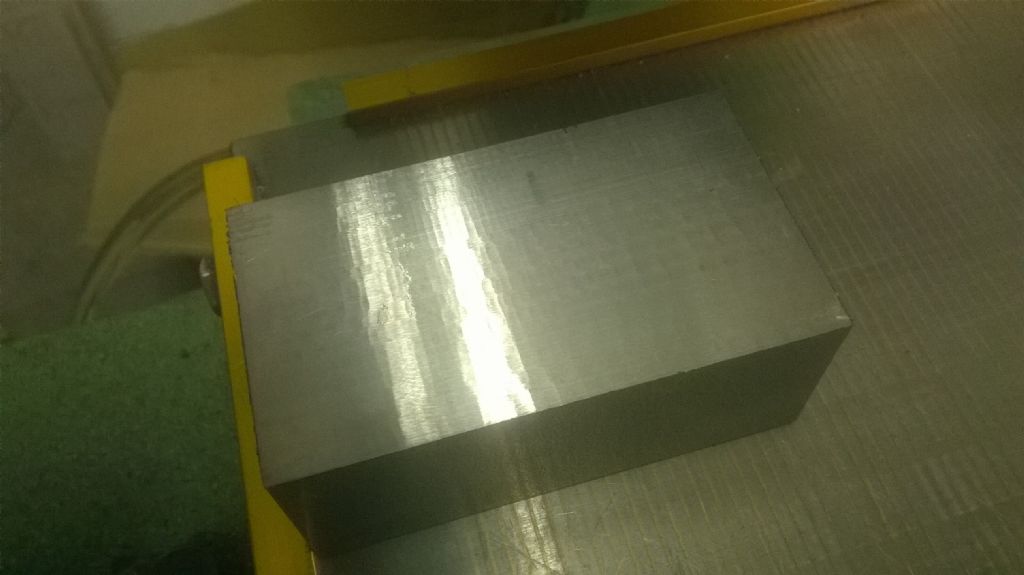

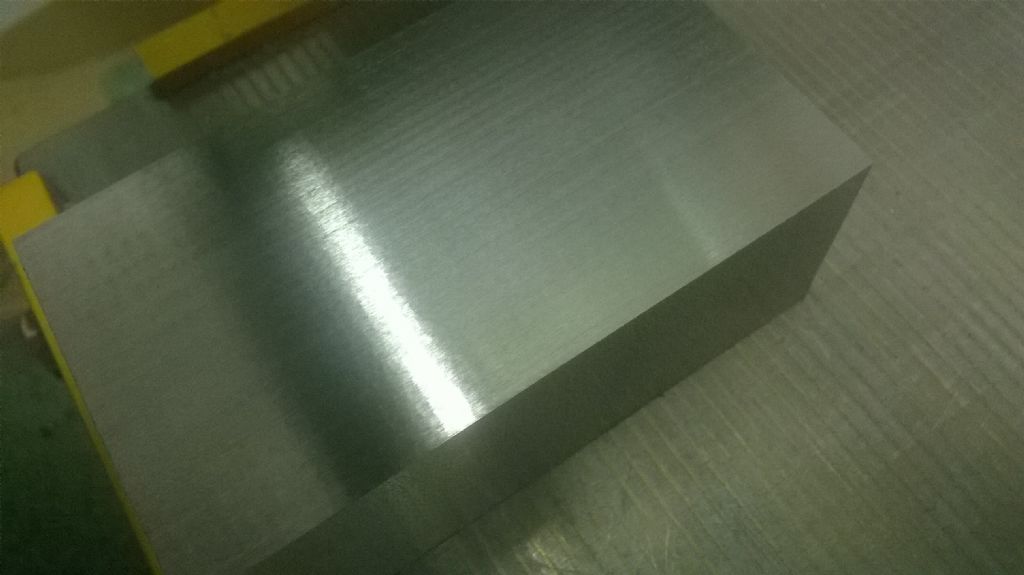

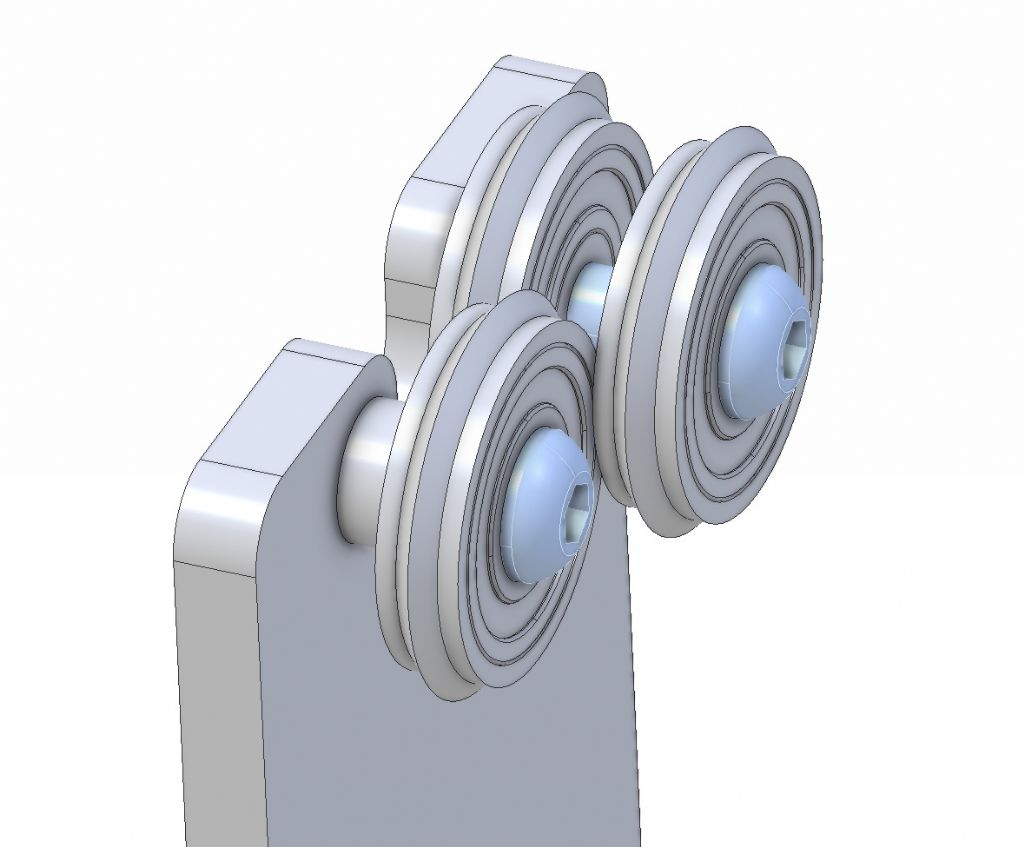

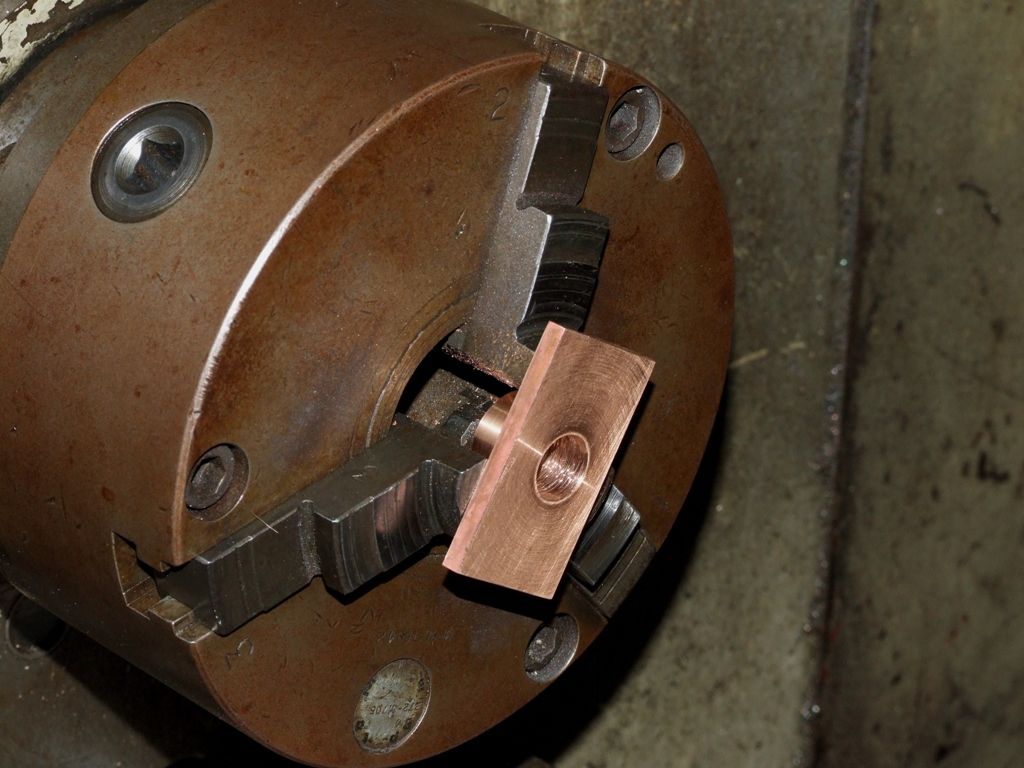

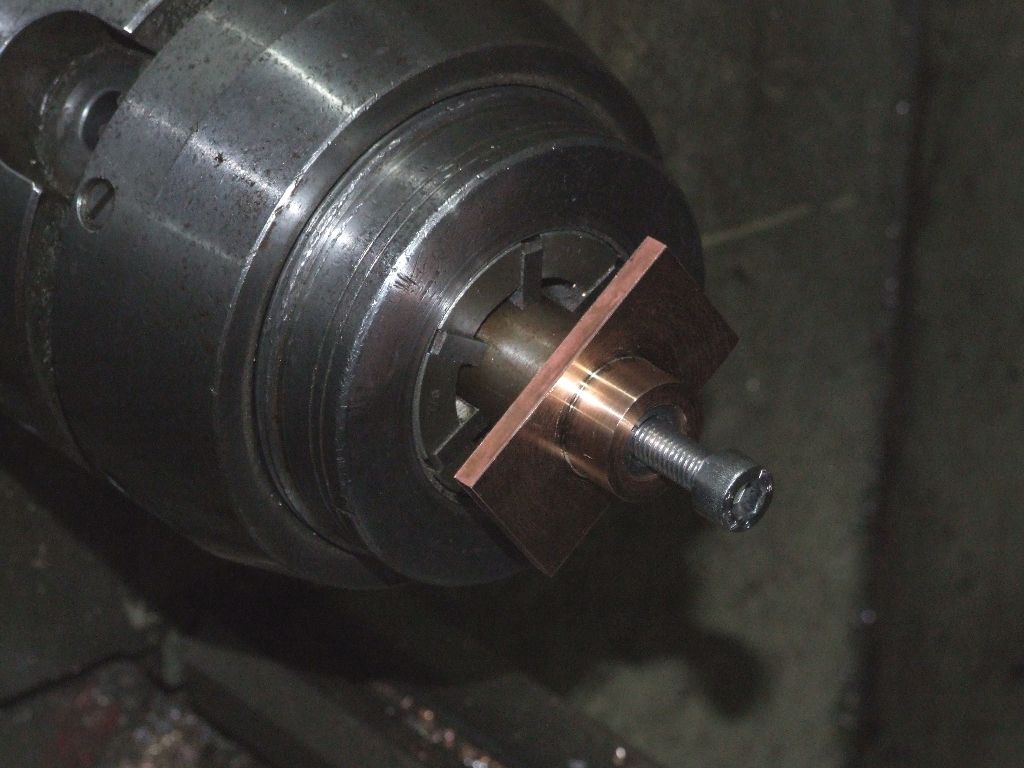

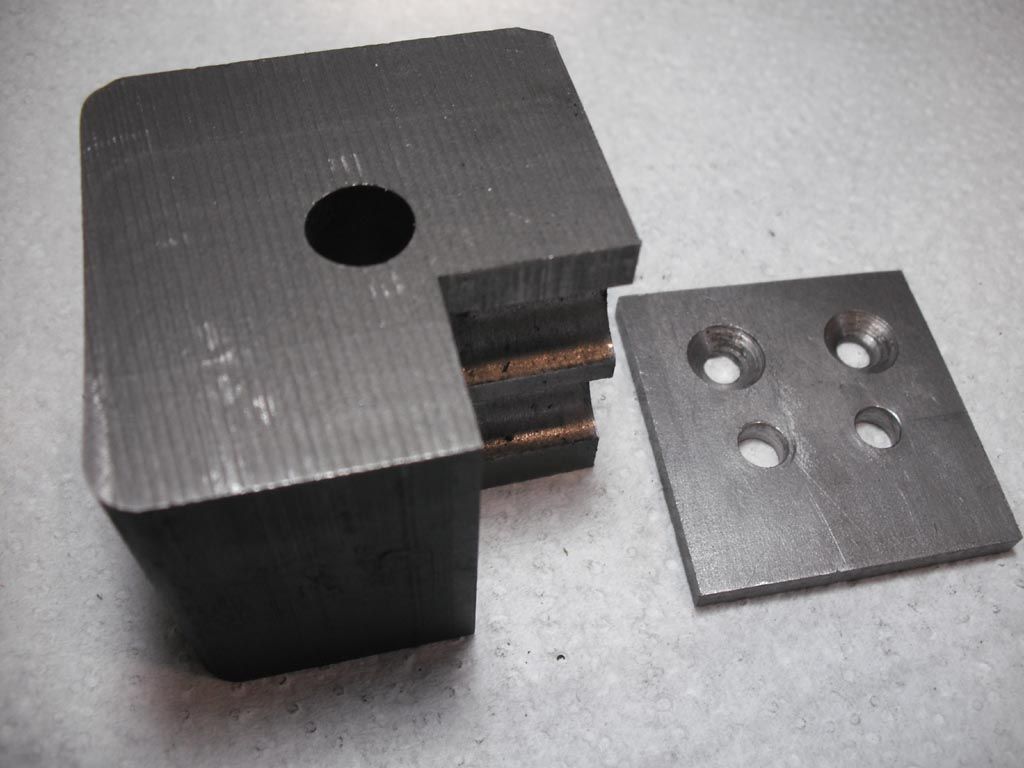

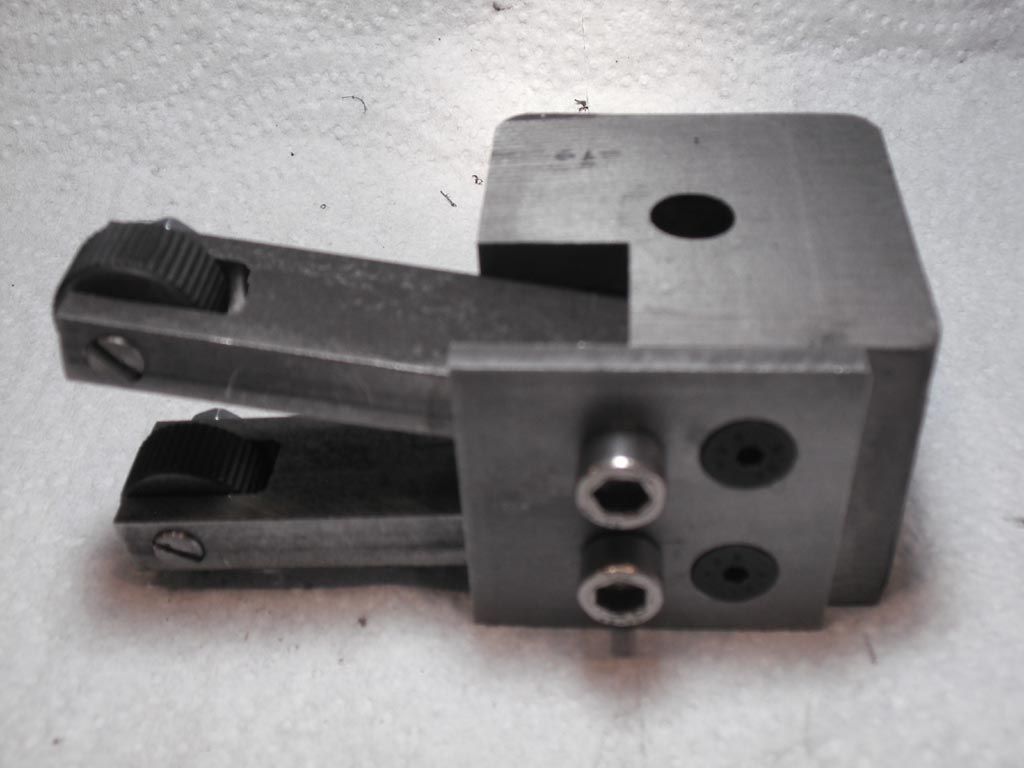

After a lot of experimenting, I've replaced the first version of the additional framework necessary, with one based on sculpting lengths of 50mm square steel tube to form combined channels and brackets. It will also support parts of the superstructure, and has to wiggle its way round the steering gear.

To make arcuate cut-outs in two pieces of the channel I chain-drilled and filed them closely enough to try finish-machining them by boring-head. That didn't work very well, and it soon proved easier, safer and possibly quicker to finish-file to the line, and as accurately as necessary.

Marking out those components in-situ was an intriguing exercise in placing a centre-point in the fresh air between the chassis sides. (In fact, on a length of 6mm thick strip G-clamped it to the frame, with its markings aligned to centre-punched and scribed data-points on the chassis.)

Blue marking-out fluid does not give much contrast on hot-rolled steel, so for these I wire-brushed the surface rust off and gave them a thin coat of aerosol primer.

'

So tomorrow (Sunday?) Try to find the filter allegedly hiding deep in my car's Gallic recesses; and see if I can at least clean it out.

'

Took the car for its first run for 10 weeks yesterday; after a worrying time when It had forgotten how to start. A round trip of nearly 8 miles over to Portland and back put plenty of joules back in the battery and oil around the engine's innards, and flushed the fuel system through.

I drove to the entrance to Portland Prison – there are fine views from there – and this finally nailed those pesky light you may remember had me puzzled a few weeks ago. I'd thought they might have something to do with the helicopter training base; but no, they are indeed traffic-lights at the prison's imposing main gate (from the site's original days as a fortress), and were obligingly going through their automatic cycles visible at night from my bedroom window a couple of miles to the North.

Nigel Graham 2.