Firstly, very efficient service from CuP Alloys – I made use of their should-be-at-Doncaster offer elsewhere on this site, and the goods I ordered last Wednesday or Thursday, just before the Bank Holiday, arrived yesterday.

So big Thank-you to them!

The delivery driver knocked on the door but didn't take a signature, just a photo of the carton on my doorstep, with me standing behind it.

'

Today:

First, walked into town and back – about 2 miles each way – returning loaded with two back-packs and a carrier-bag in which was a Pyrocantha (Fire-thorn) sometimes jabbing my leg with a stray thorn.

The walk was eased by an old railway route now an asphalted cycle-track and footpath, cutting off a large corner formed by the main roads and reducing the climbing over an intervening ridge – the railway cut through it.

Planted the fire-thorn with a view to training it eventually along the boundary wall for added security, along with a dog-rose I had rescued from growing through points on a small museum's narrow-gauge railway.

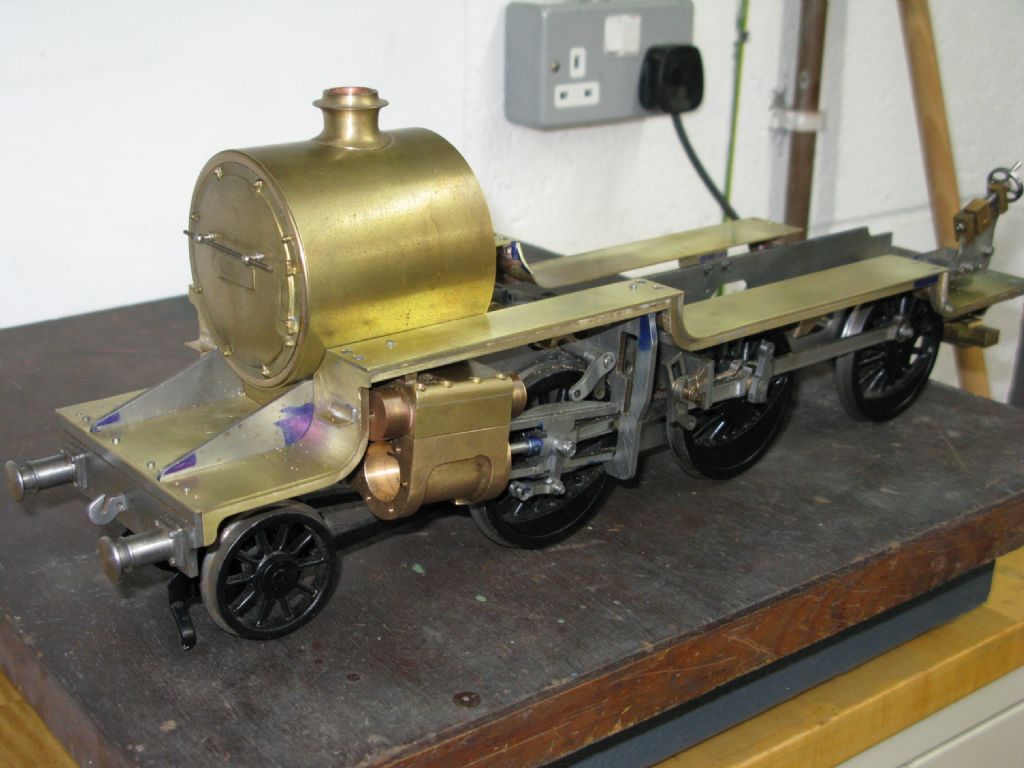

This took some thinking. I did not want it to obstruct the side-gate, or more particularly, obstruct moving the model steam-lorry through the gate, so I wheeled the vehicle to the gate, and moved the shrub still in its pot, around to find the best position also to not take up too much lawn, shadow existing plants, or be in the wall's rain-shadow. I bet Gardener's Question Time doesn't have many questions about spikey bushes in the way of miniature steam-wagons.

.

Then completed all but a few details on the workshop's travelling-hoist cross-beam, by welding two assemblies each consisting of 4 pieces of square-section steel tube. I took advantage of the long evenings and cold wind driving the neighbours indoors, so not disturbing anyone with bursts of angle-grinding outside the workshop.

"Welding"… LOL! Throwing molten steel at the joints on the 1-in-50 occasions I could create and maintain an arc.

I use welding as little as possible, and only to take light loads and where appearance doesn't matter. These are the only welded components on the frame, and most of their stresses will be taken by bolts.

16 joints each one-inch long, in 3mm wall square tube. I estimated the yield of rod – i.e. length of electrode used to length that became a functional part of the structure – about 10 to 1, in making enough welded and re-welded bridges of fused steel between gaps and slag, to hold the parts sufficiently.

That's why I usually avoid welding – making lovely, tidy, cohesive, slag-free, full-depth weld beads the full joint length in one pass from a single strike is a hermetic art, like playing the piano to Rachmaninov concerto standard, or unravelling the dark mysteries of the mathematical matrix.

Steady hands helps too, and mine never were, but even guiding the electrode over a (gloved) finger didn't help much.

Flattened a curve or two (or 16) – of lumps of steel and slag – and squared everything away for the evening. Just some minor turning, then the frame can be dismantled, cleaned and painted; then erected. Phew! Only I will have to find suitable supplies of fastenings, a bit tricky at present. Might have to be by mail-order..

A sign of how dry the weather has been, even at night, is that despite leaving the frame outside on a few nights, there are only light traces of rust on sawn and drilled surfaces. They won't harm it, and it will soon clean off.

Nigel Graham 2.

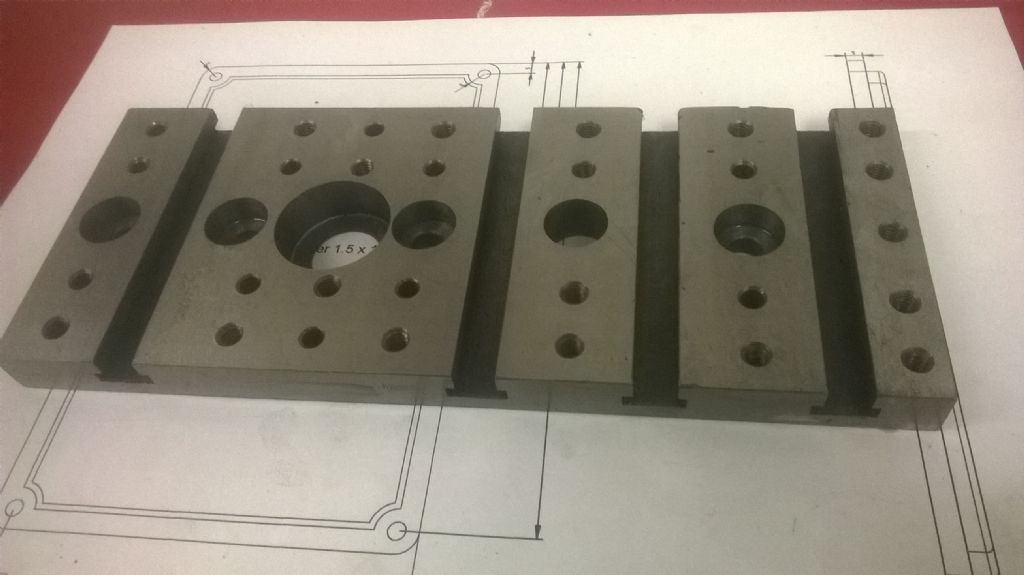

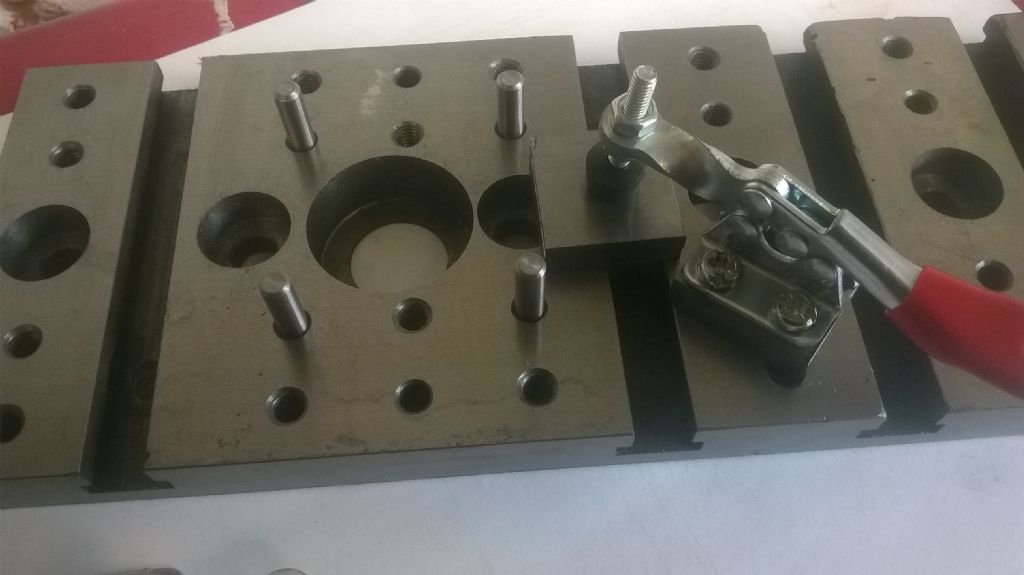

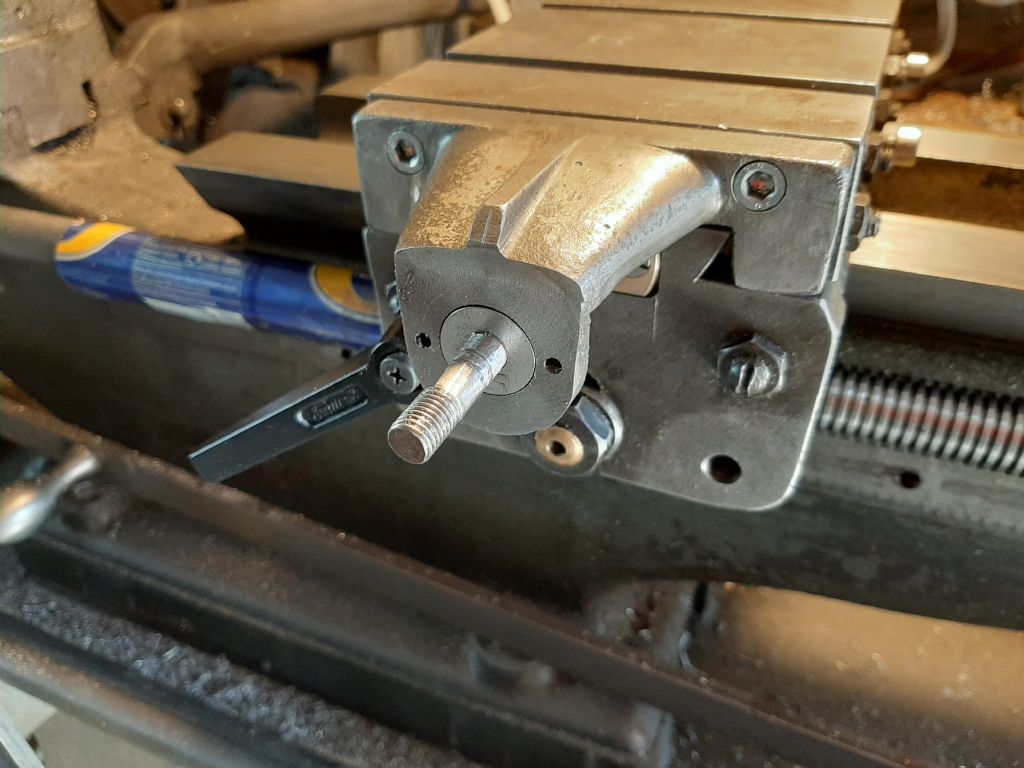

as all was working ok last time in use, I did a bit of deducing, I was cutting a deep slot in a wedge jack body starting with 12 mm hogging cutter followed up by a 1/2" 4 tooth end mill 0.5 mm doc which shouldn't have been a problem,when the drive unit 'popped' & magic smoke appeared,obviously the PWM unit.

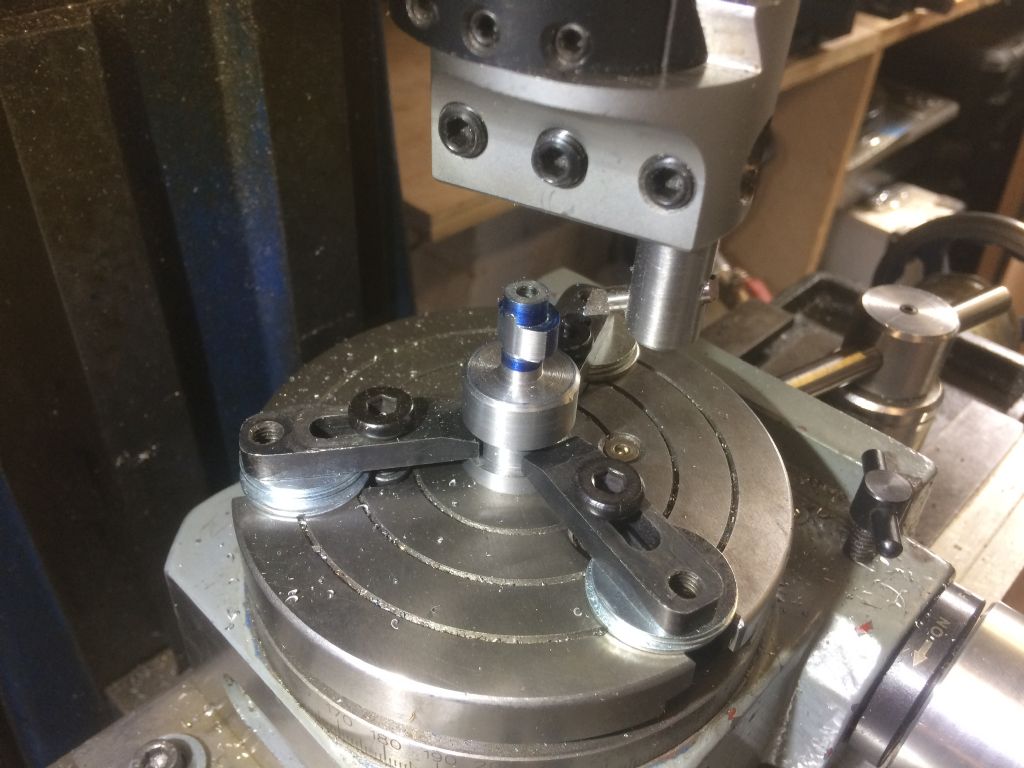

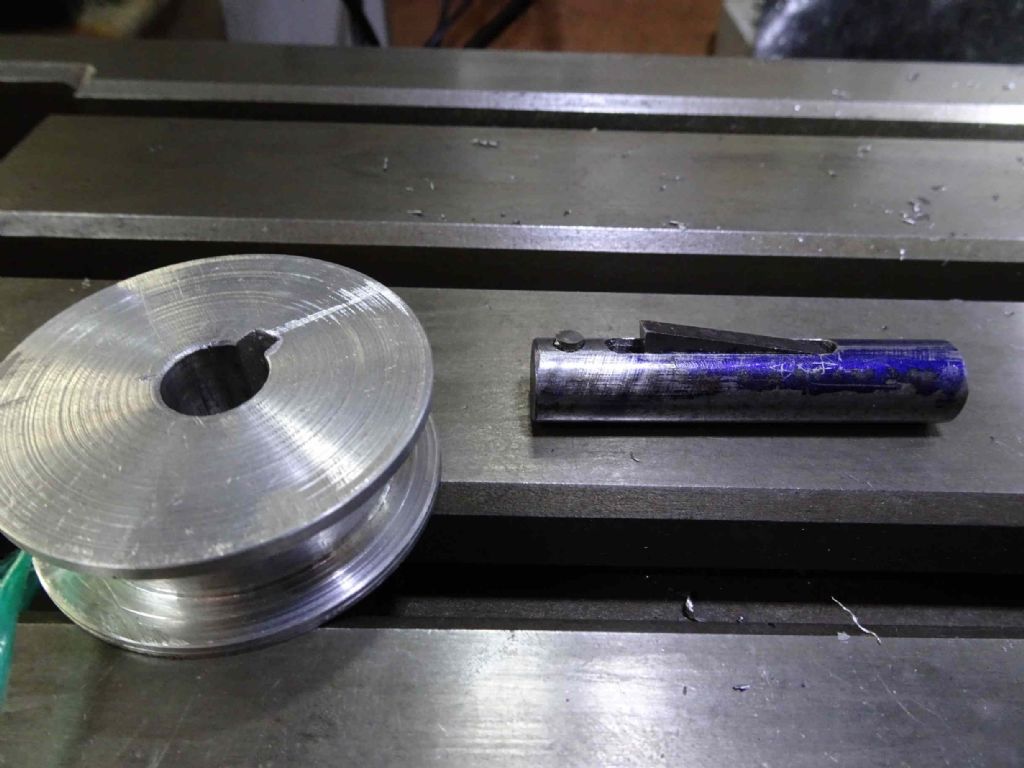

as all was working ok last time in use, I did a bit of deducing, I was cutting a deep slot in a wedge jack body starting with 12 mm hogging cutter followed up by a 1/2" 4 tooth end mill 0.5 mm doc which shouldn't have been a problem,when the drive unit 'popped' & magic smoke appeared,obviously the PWM unit.