Continued putting my Harrison L5 Lathe back into use.

By today I'd already given it a 3ph conversion courtesy of Newton-Tesla (I told them the machine and they chose the appropriate conversion set.)

The new motor is on an adjustable bracket arrangement on the steelwork for what will be an overhead hoist arrangement, and above the headstock. This puts the motor up into cleaner conditions and allows the lathe to go back close to the wall. I made the adjustable tie-bars involved, from bits of scrap miniature-railway track. The original, large, 1-ph motor was on a massive steel box welded to the back of the cabinet, too greedy of space in a cramped workshop so now very un-welded. I'll also need to chop the original change-wheel guard, or make a custom one..

The inverter and "pendant" control-box live on the wall above the tailstock.

Today's task was adding oil to the headstock and replacing the cover, with a new greaseproof paper gasket cut from the bag inside a cornflakes box. Then oiling round, and carefully testing the machine.

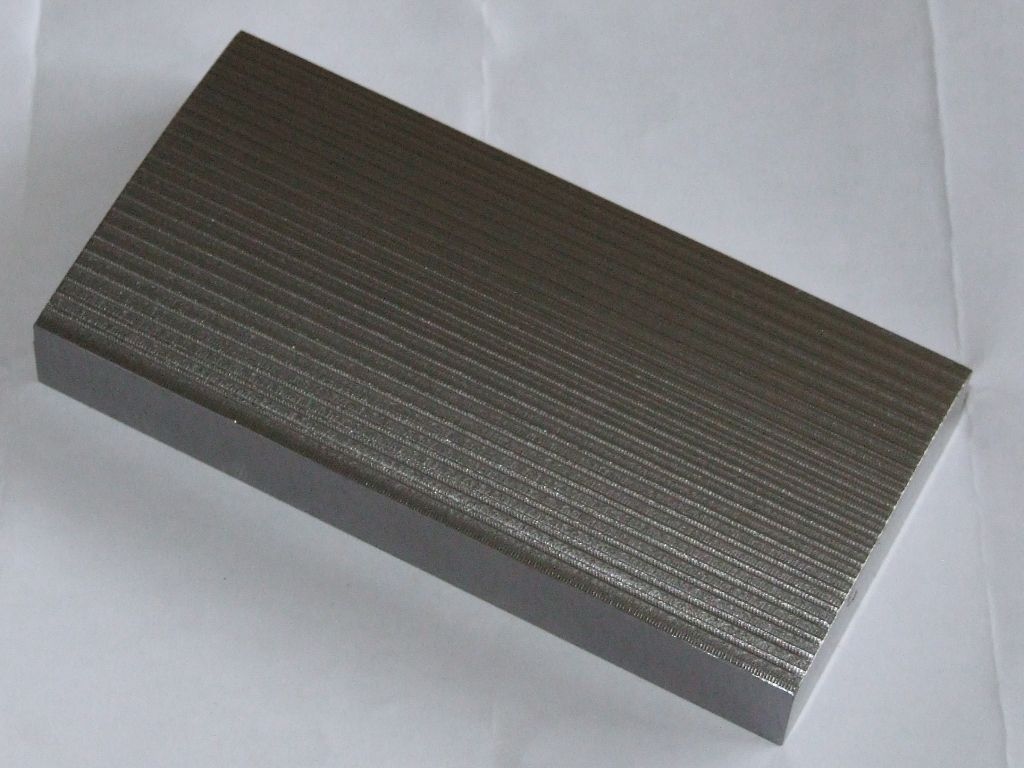

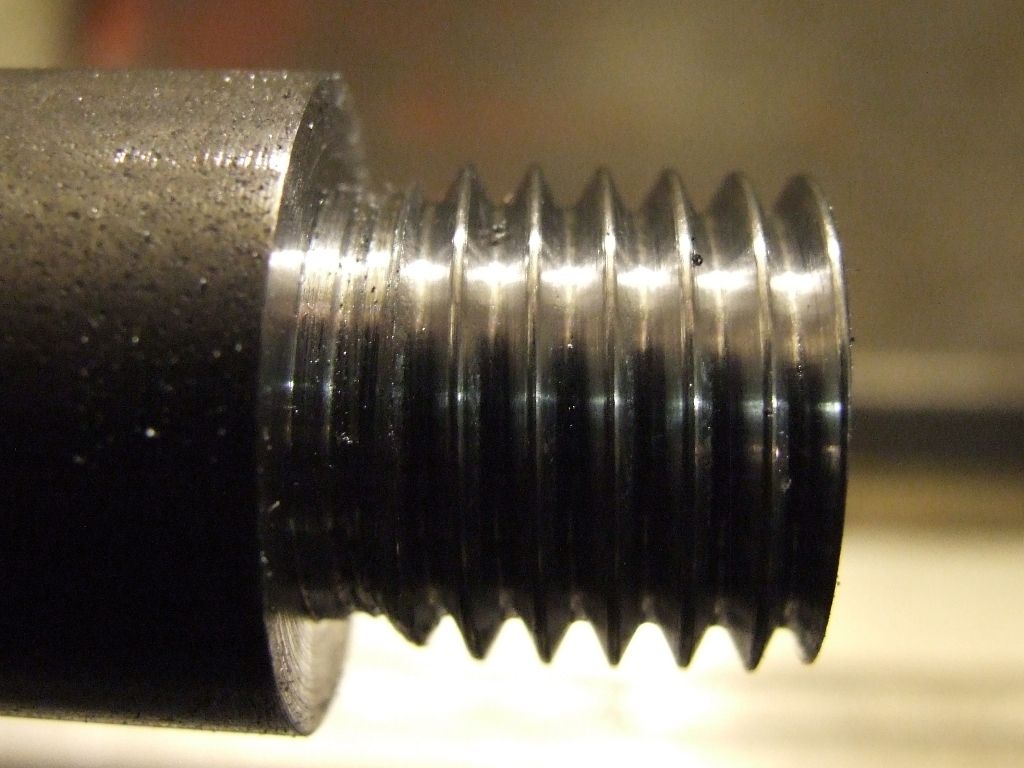

Finally, sorted out the "pre-owned" QC tool-post I'd acquired for it. It needs appropriate stud bushes but they are no problem. However, I discovered the three blocks with it, all have the same clamping and guide grooves but slightly different tool channels and screw-threads! For consistency so I need just the one key I have, I will have to make the replacements for missing locking and clamping screws, with square heads are equal across the set.

So that's the next shopping-list: more QC blocks (2 or 3 more will probably be sufficient), and replacing missing change-wheels.

Ummmm, how can anything be "pre-owned (pre– booked / ordered / existing)? Unless you are Doctor Who?

Steviegtr.

Steviegtr.