Once must be careful when starting a post with ' I Finally completed my XYZ thingy…'.!

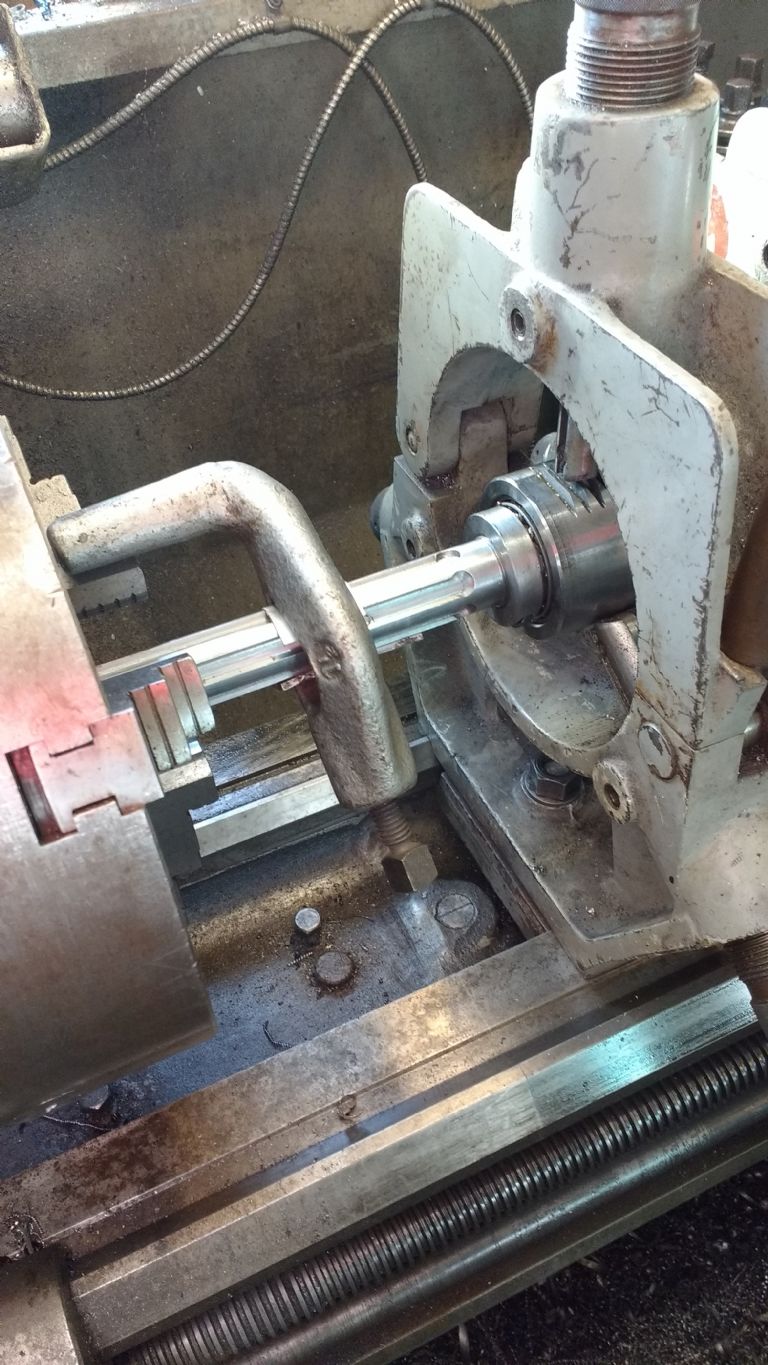

Some post back I showed my 'finally' completed stepperised rotary table/Hobber and the electronic controller I made for it.

The controller did angle steps, division steps , continuous rotation and a hobbing mode. And that was done…

But, I had left out some very obvious requirements..The is no manual mode to rotate the table manually, as you would a none electronic table, and no way to jog the table to a set position to begin stepping from of hobbing from.

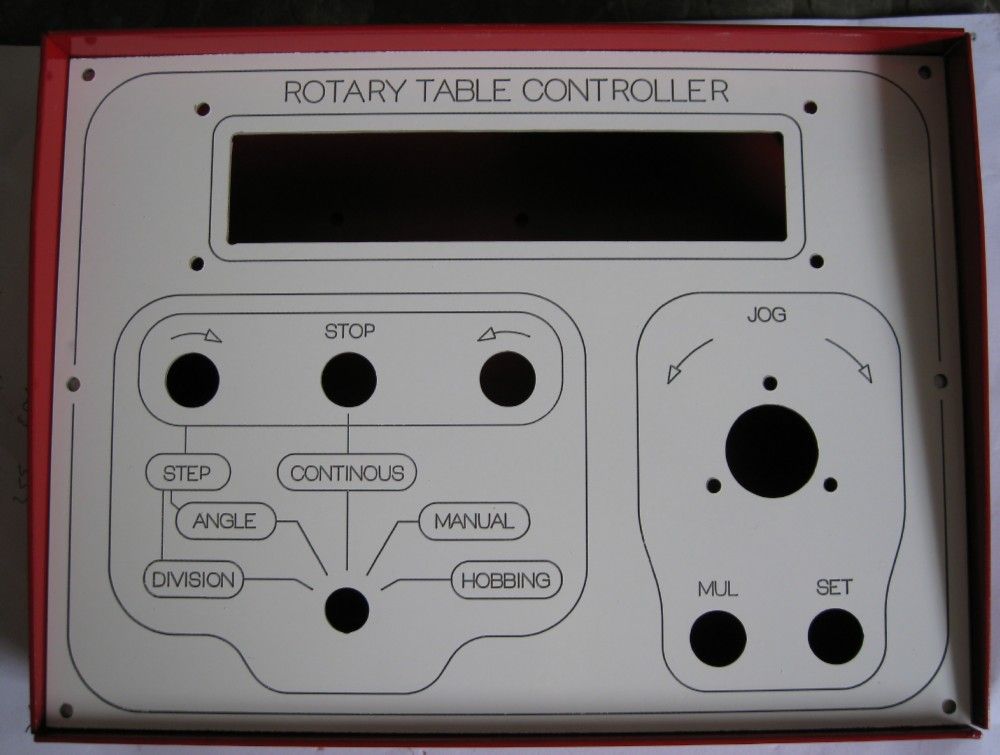

So..Here is the finally finished all new version…With a manual mode and the controls a little better consolidated.

Had to make a new housing for it – the last ( nice) plastic box was all used up and I could not find more..

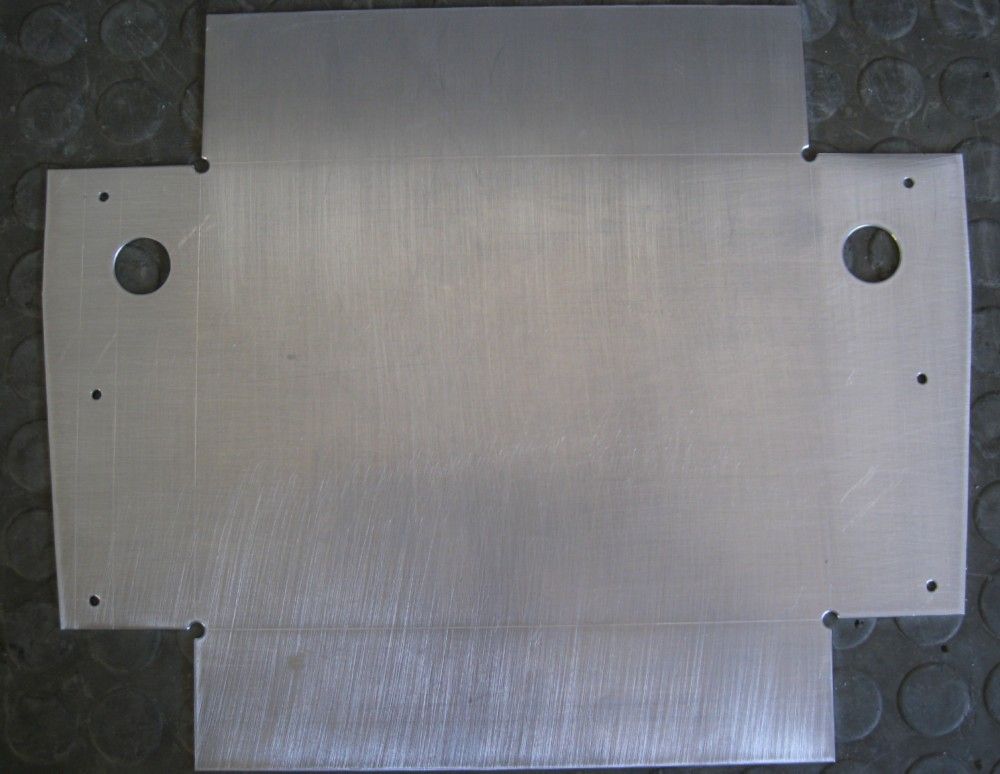

Ready to bend..

And to paint..

And the new front panel engraved and routed.

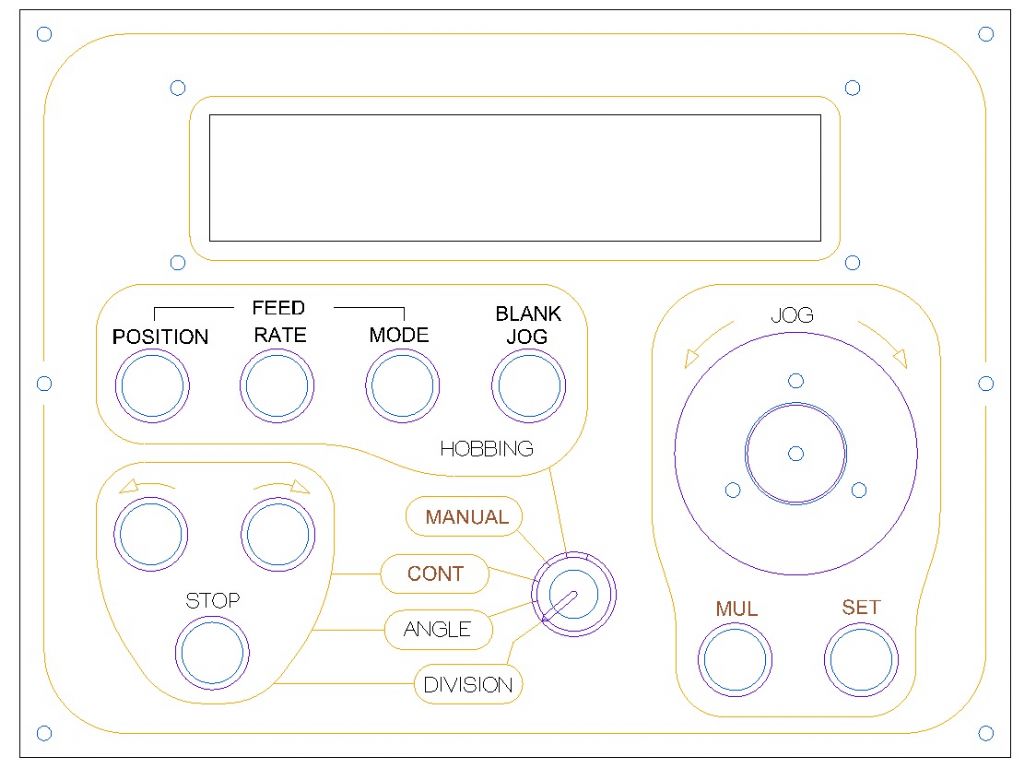

Paul White ( also a fellow forummer) iis going to built one as well, but with some added features – he has two rotary tables , one small, one large, with different gear ratios, and a gear hobber with yet a different gear ratio and autofeed on the hob.

Also a few more controls..

So Paul's panel functions are so:

Joe

Steviegtr.

Steviegtr.