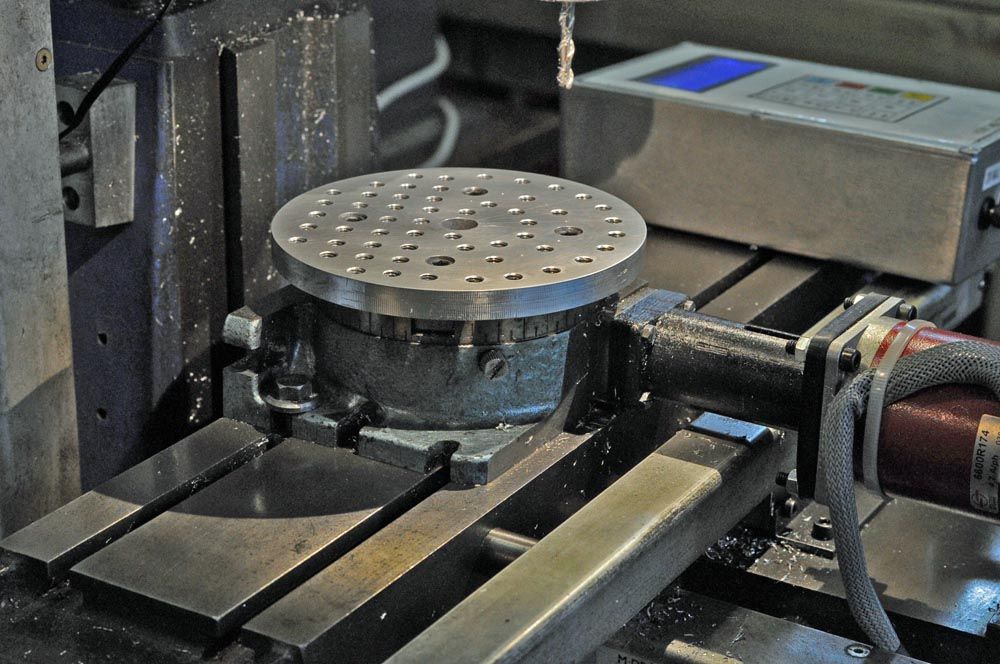

Finished the special V-nuts needed, and fitted the long-axis magnetic strip for the DRO to the Myford VM-C milling-machine table with them.

This means the table no longer has travel-stops because the only way to fit the profile was by the V-nuts in their slot, and of course the stop-block had to come off too.

These strips have to be fitted to quite close parallelism but I think I managed it eventually. The drawback with that design of encoder strip is that you cannot remove it from the machine without destroying the magnetic strip itself, because it is stuck on across the mounting-screws.

While at it I tried adjusting the gib. That proved problematical, with very little available travel on the adjusters, and the two locking-screws doing nothing at all. I took the screws out… Someone had sawn them short!. I made up little steel slugs to take up the space, so I can now lock the table's long travel at least.

The Myford mill is not designed to take DRO encoders, though a 2-axis system is listed in the service-manual as an accessory. My thinking with the Y and Z travels is to put the strips on backing bars screwed to the machine outside the profile's width, since there are no machines surfaces available for them and I will probably need to make special spacers. The Z-axix encoder strip will be the worst thanks to the shape of the machine body.

There is another advantage to that approach. I can assemble the profile and its backing bars(s) in comfort and good light on the table, rather than in the very awkward, cramped, gloomy and grubby conditions around the machine.

Steviegtr.

Steviegtr.