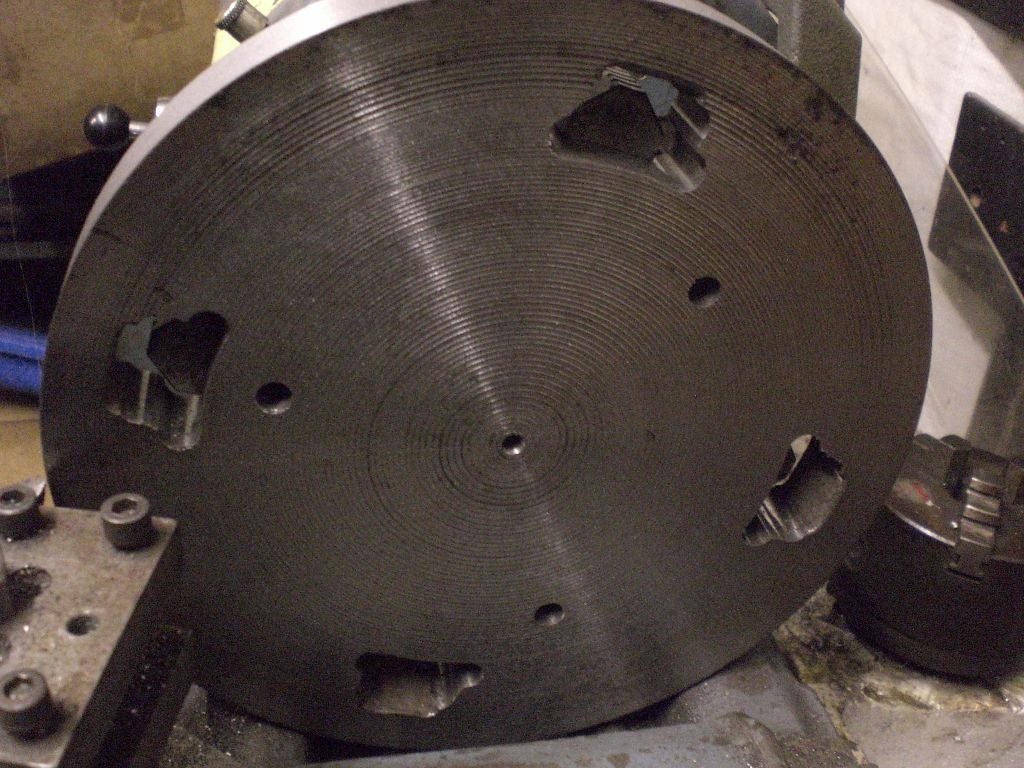

Hi, well today I started to make a backplate for my slim 6" four jaw chuck, so that I can mount it on my milling machine table. This is a bit of a challenge, as I need at least one dimension to be about 8" for the bolts that will hold it on the table to clear the chuck. The problem being that the biggest chuck I have will only hold 6" in diameter. I've had this cast iron disc, which is 9" in diameter and about 1" thick, which has four square holes at about 90 degrees to each other crudely cut into it and the inside edge of them is about 6" diameter. No idea what it was for, but on the side that has had machining, it has 17 lbs stamped on it. I'm just guessing it was a blacking plate for a pipe.

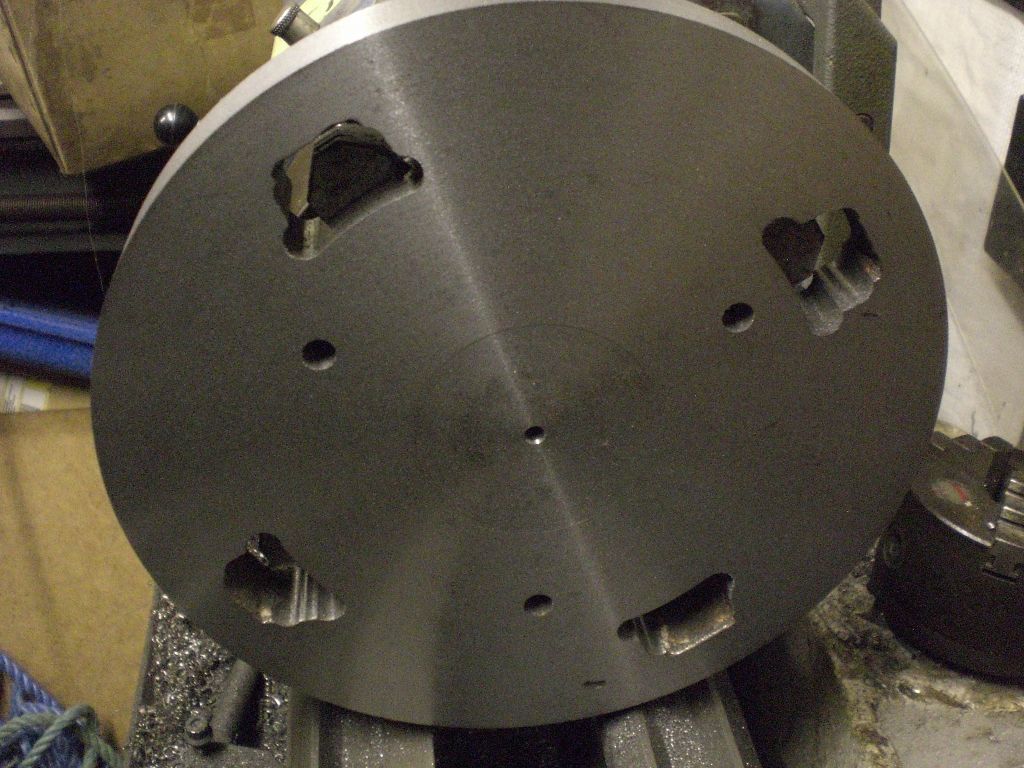

Here's where a light bulb moment came to me, but it would require a bit of work. First of all, three 8.5mm holes were drilled 120 degrees apart on a 60mm radius, to be able to fix it to my rotary table. It was then fixed and centred with a washer between the disc and table on each bolt. I then began milling the inside edge of each hole wide enough for the jaws of the biggest four jaw chuck to fit in.

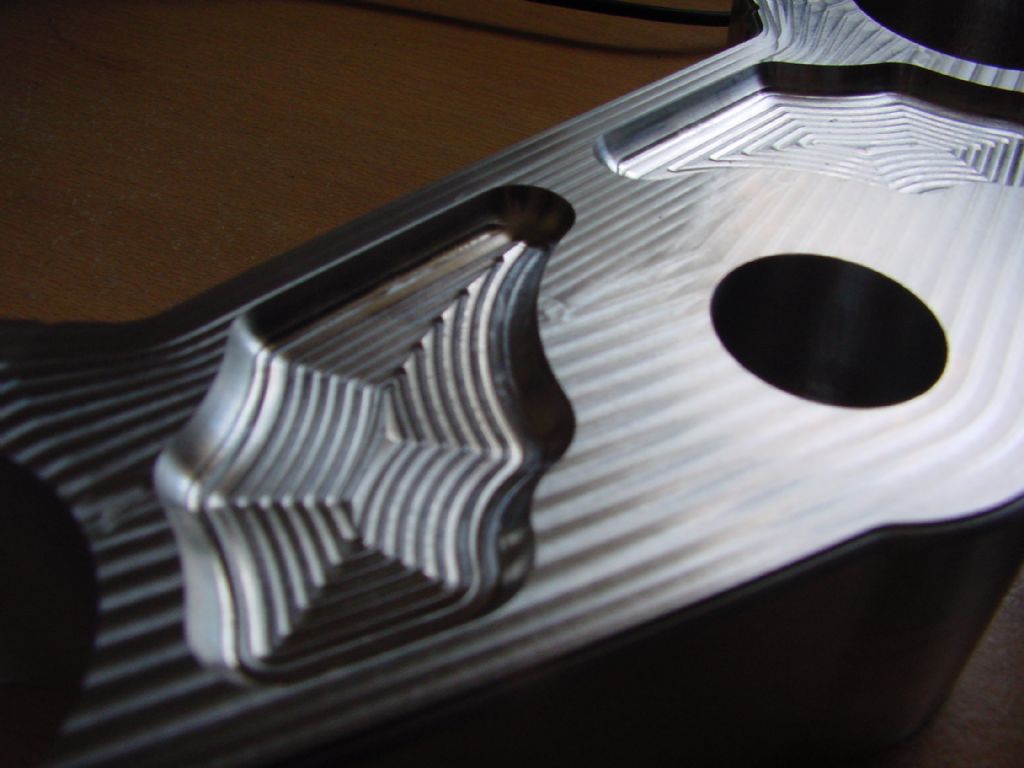

Once these were all done, the milling machine table was moved to the left and each side of the holes where widened a bit more and when they were all satisfactory, the top of the disc was milled where the flats of the jaws make contact and a jaw was used to make sure all was good.

One of the holes that were used for holding the disc to the RT, came right in line with one of the square holes and I had to mill the top around this, but when all the milling was finished, this bolt was removed and the area around the hole was slightly undercut with the miller.

Next step was mounting the disc on the four jaw on the lathe.

Regards Nick.

Edited By Nicholas Farr on 12/03/2017 00:35:44

Another JohnS.