Les ; again thank you .

Rather than unbolt the machine and swing it away from the wall , I removed the front plate ( on which the speed indicator is mounted ) and found just behind it the filter board , what luck, thought I .

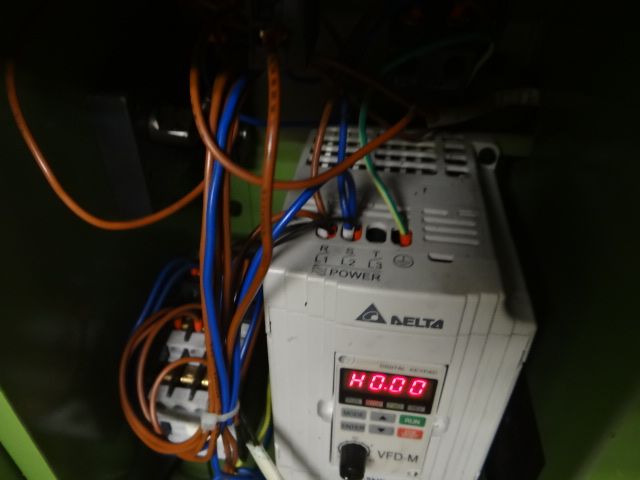

Not being versed in the arts of the electrician, I could see the terminals you spoke of , but they appeared well protected with no opportunity to touch my meter too, there were also out terminals with similar markings . That aside , I carefully rested the front plate securely, and replaced the plug into the mains socket , I then switched on and to my surprise, the display light up ? . Why I have no idea , but I accepted this stroke of good fortune and replaced all to its normal state .

I have since been starting and stopping the machine quite normally whilst cutting the thread that I started out on .

Les , I must thank you , and all who contribute when the likes of me have a problem , if you don’t fix the issue , you at the very least give us the confidence to have a look and even a go at doing stuff we would probably shirk away from otherwise . Thank you .

All appears well with the Lathe now .

Les Jones 1.