Hi John,

I have read the sequence of dimensions back to front. I transposed the width with the height. I am assuming the width dimension is the total width of the table including handles. (These values are from the Warco website when you download the PDF file if you click on "Spec sheet"

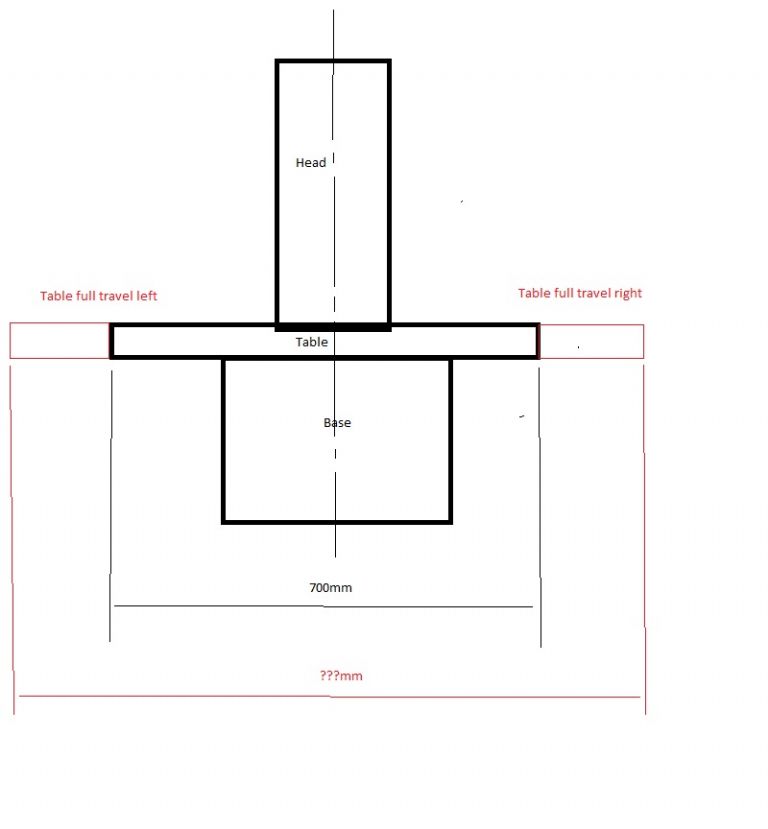

For the WM14 I get the width as 500 mm and the table travel as 220 mm (= 720 mm)

For the WM16 I get the width as 950 mm and the table travel as 485 mm (= 1435 mm)

Sorry for the error but we still have different values for the total width of the table so it looks like we need someone that has these machines to measure the total table length including handles.

Les.

Edited By Les Jones 1 on 24/03/2013 17:42:20

Edited By Les Jones 1 on 24/03/2013 17:42:58

Edited By Les Jones 1 on 24/03/2013 17:43:44

Edited By Les Jones 1 on 24/03/2013 17:44:03

petro1head.