Nigel,

Thanks for the compliment. I had a good English teacher in school, also my mom spent quite some time to study with me in the summer, one hour after lunch, while I could hear other kids running around and playing outside. I also played a lot of computer games, back then (early 90's) every game was a non-localized pirated copy, so I was highly motivated to look things up in the dictionary  Also the Internet was quite small back then, to find useful info, English was a must. These days kids can play games (and find websites on most topics) in their native language, so they are not forced to learn.

Also the Internet was quite small back then, to find useful info, English was a must. These days kids can play games (and find websites on most topics) in their native language, so they are not forced to learn.

I agree with your comments regarding safety, and will do my best regarding that.

Ian,

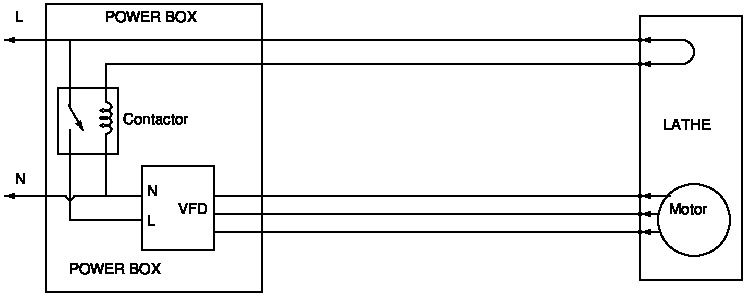

I will try to mock it up and see if your suggestion can be workable. If I go ahead with this idea, the VFD enclosure will need to be made well-protected from any swarf/dust produced during lathe operation.

With regards to sourcing the motor, it shouldn't be a problem. Here I found the specs of a motor that fits without major modifications. I've asked the author about it, he said it fits, but he had to get rid of the wiring box on top of the motor, and to make a custom 3D-printed motor mounting bracket. The original motor is frame size 63, the new motor is frame size 71. However, the old motor's shaft (and matching key) are of the same size as today's frame 71 motors (meanwhile, today's frame 63 motors have a smaller shaft and key).

Aviation just sounds cool, probably  . Same as "aviation aluminum" is sometimes used to describe some products…

. Same as "aviation aluminum" is sometimes used to describe some products…

Robert Atkinson 2.

Robert Atkinson 2.

Also the Internet was quite small back then, to find useful info, English was a must. These days kids can play games (and find websites on most topics) in their native language, so they are not forced to learn.

Also the Internet was quite small back then, to find useful info, English was a must. These days kids can play games (and find websites on most topics) in their native language, so they are not forced to learn.