Posted by old mart on 14/01/2020 13:33:52:

I'm sorry to say that you will be doubly confused after reading through this thread…

Don't know about Gerard, but I certainly am!

I think the problem is the various contributions mix several different points about distribution systems as well as 3-phase motors; starting them, the pros and cons of star vs delta, 200 vs 400v, speed as effected by volts, frequency and load, and the special case of bodging a high voltage motor to run at all from a low voltage VFD. Doesn't help that I find the external description of 'why 29Hz' obscure; I think I understand what it means in terms of flux, but not how it alters the price of fish in ordinary circumstances.

Gerard's 13:06 post today reveals he has special circumstances. His motor is 380V, so to get it to spin with an ordinary VFD suggests the 29Hz trick is appropriate. But it's an expedient in that I don't think the motor is working at full potential, power or speed. (However, if the arrangement is good enough to get Gerard's machine working satisfactorily, carry on!)

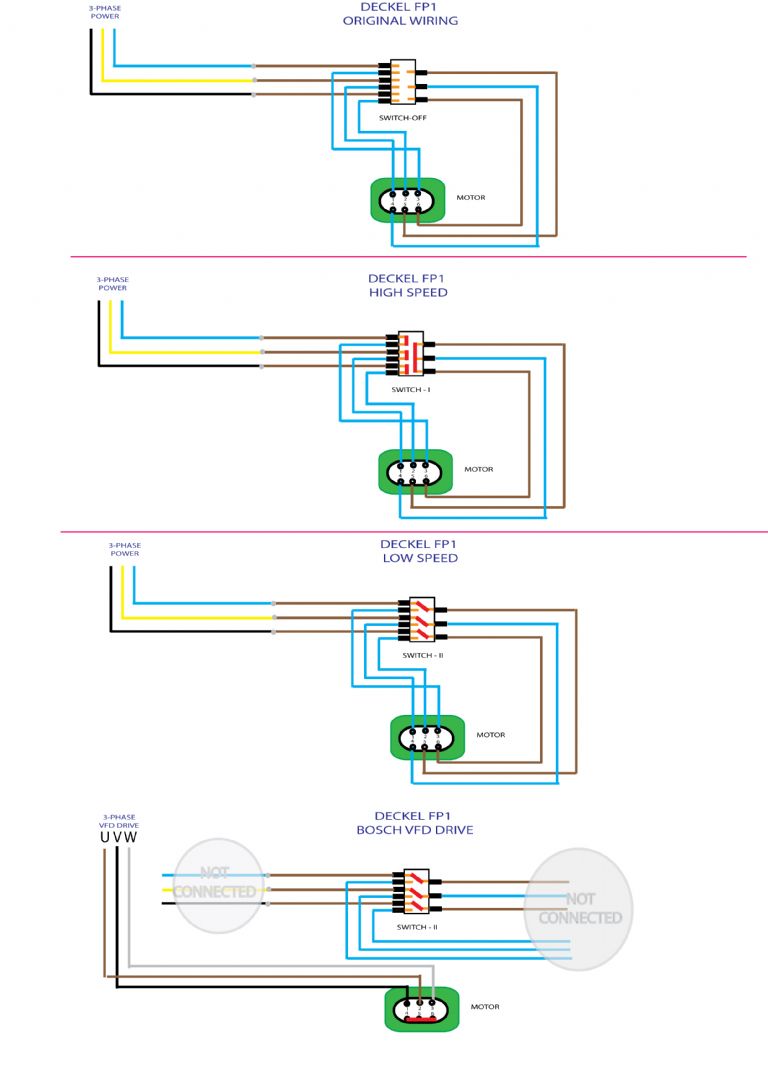

Gerard says: 'There is a switch to switch it from low speed to high speed. This switches it from Star to delta ( or Delta to Star – I will have to check)' Normally changing from star to delta wouldn't alter a motor's synchronous speed. Isn't it likely Gerard has a switched pole motor like a Dahlander?

Reinforces my view about buying ex-industrial machines: check the electrics! While most have motors that can be driven happily by an inexpensive VFD, others are far more challenging. I'd be nervous buying a machine that mixed 3-phase and single phase functions together on the same feed because that's simple-VFD unfriendly. Is "High voltage and two speed" another combination signalling "buyer beware" because the electrics are likely to need special attention?

Dave

Anonymous.