Posted by Andrew Johnston on 08/01/2020 22:45:37:

Posted by John Haine on 08/01/2020 15:58:09:

…

…

Not sure I agree with SoD on a couple of points. The use of high voltage for power transmission is not connected with the 3 wires needed for 3-phase distribution. It's equally valid for single phase. … he big advantage of 3-phase over single phase is that one can transmit three times as much power for an increase of only 1.5 times the amount of cable.

…

Not sure what SoD means when he says 3-phase is self-balancing. If you have unbalanced phase currents and a neutral then there should be a neutral current flowing. But, for instance, most electric motors don't have a neutral connection! So voltages start to go awry.The utilities go to great lengths to ensure that phase currents are balanced over a large number of individual loads. A 3-phase generator, and 3-phase transformers, are not going to be happy if the phase currents are unbalanced.

Andrew

The first point, I agree! My poor wording, I didn't mean high-voltage was exclusively a 3-phase thing. Works just as well for single-phase and DC because W=VI and W = I²R. As I = V/R Big Volts = small losses.

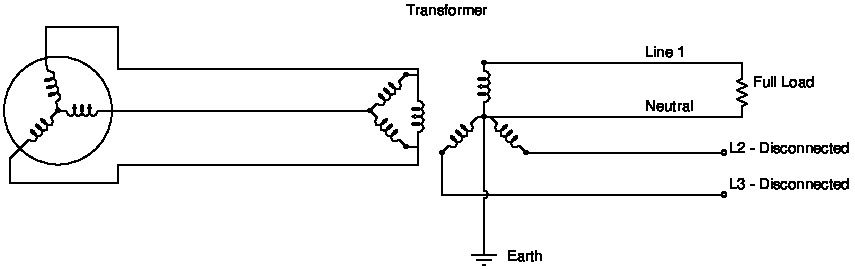

I may be talking rubbish again about 3-phase having balance advantages due to misremembering or misunderstanding what my dad told me. Unlike me he was a qualified Electrical Engineer and could do the maths, though it has to be said his job didn't keep his skills well-honed! Anyway, I don't mean that 3-phase systems don't have balance problems, only that they are less vulnerable. In this diagram the supply side of the transformer is connected to a 3-phase generator, but only one phase on the consumer side has a load attached. (Not by design, but imagine someone crashed into a pole and broke the other two live wires.)

By 'self-balancing, I mean the generator doesn't bump because only one winding is generating power while the other two idle due to an odd load. The generator is isolated from consumer-end phase imbalances by the transformer. The magnetic flux in the transformer's core is generated by all three input windings and the same flux is shared by all three output windings. It's not fatal if only one phase is drawing power. Obviously not ideal or efficient but having a phase or two disconnected certainly isn't disastrous. Normally the transformer would be wired to balance the load, balanced phases are a good thing, but unlike riding a motorbike at 120mph, perfect balance isn't mission critical!

More. My diagram shows only one generator and one transformer: in the real world there are many generators and transformers in the distribution system, and as they all tend to minimise phase imbalances, the system as a whole is resilient, even in the face of faults and atypical customers.

This is my understanding: I hope it's right! Given my diagram, anybody out there able to calculate the current flowing in each generator side phase when only one single phase consumer is taking power from the system?

Dave

Anonymous.

.

.