Thanks for your interest gents

Some people say there is a black art in making injectors:- but all that is really needed is a good understanding of how they work this coupled with some careful machining and patience.

I was given a set of instruction by my friend that I followed and was amazed when the first one worked so made another 4 not one of which worked remade the cones being extra carful and they all worked.

There are plenty of good books out there the best for theory is probably D.A.G Brown's (Miniature Injectors Inside and out ISBN 1857611349) but with all respect to DAG his body design is far too complicated, so to his is method for making the cones. LBSC on the other hand is far to simplified relying on good luck more than anything.

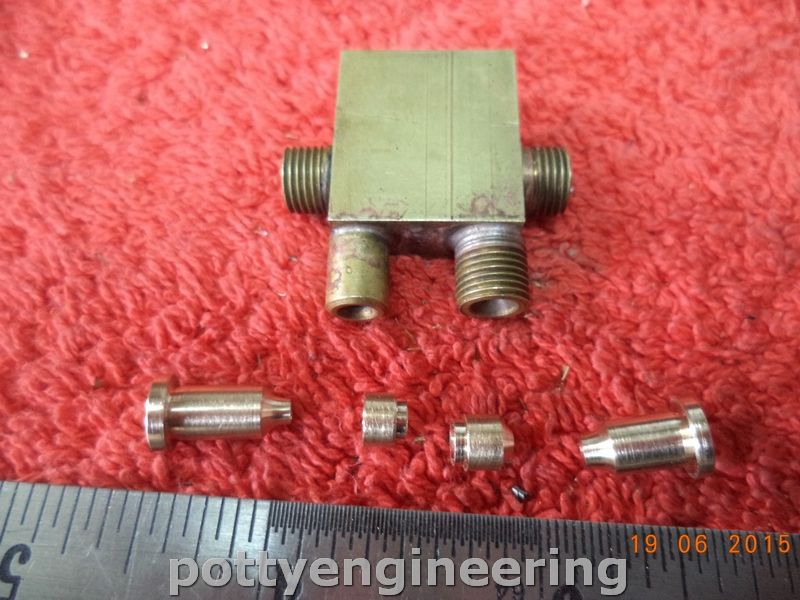

This is the first injector I made

And some of the tools required

As for an article there have been lots of articles in the magazine on making injectors I don't know if the Ed would want any more.

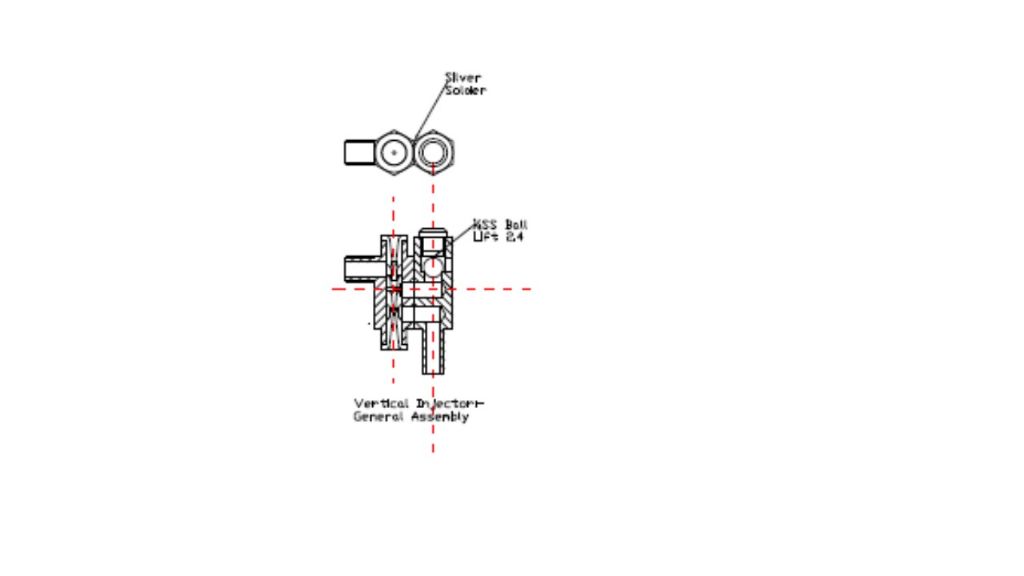

The vertical injector body is made in two parts from hex or square bar and can be made in the lathe with the cross holes drilled the two parts can be silver soldered or soft soldered together. The cones:- which are the critical parts, need carful manufacture to get the critical features correct are made the same as any other injector. Our vertical design uses two over flows the top one (copper Pipe) takes the flow from the combination cones it shuts off when the clack valve closes due to the vacuum that's created, the bottom takes the surplus water from the delivery cone.

I think the main advantage of the vertical design is that you can simplify the pipe runs (less Bends) by moving the water feed onto the best suitable face:- I could have had a straight pipe from the water feed valve into the injector if I'd had its water coupling on the face, facing the valve, but I didn't twig onto this until I had the injector made.

Stew

Edited By Stewart Hart on 19/02/2019 07:56:36

Stewart Hart.