Posted by noel shelley on 19/01/2022 17:08:39:

… IF it's a one off then yes CNC would possiblly be quicker BUT you have to write the code, I have to make a pattern, BUT once done I can do 6 or even 10 at one time, CNC does them one at a time. There's room for both technologies as each has it's good points ! … Noel

Is there a Production Engineer in the house! She would be able to calculate the break even point.

Where the break point is depends on many factors, but CNC competes well into the middle volume range. Multi-axis CNC machines are extraordinarily flexible and offer special efficiencies. Being general purpose, any machine that's available in the same factory, down the road, or overseas can be put to work. They can all take on a variety of different jobs. If a machine shop happens to have CNC machines idle, they can all be utilised until higher priority work arrives. High-utilisation helps overcome a serious manufacturing problem: any machine-tool that's not cutting metal is wasting loads of money! Labour costs are low because a single minder looks after many CNC machines and it might even be possible to run machines unattended overnight with the lights out. No expensive furnace, specialist staff, moulding floor, cranes, pattern-store or other foundry paraphernalia.

Traditional cast-iron moulding is comparatively labour and energy intensive. Manually machining bar-stock with lathe and mill is probably the cheapest way of making one-offs, and I'd guess moulding is cheapest when tens of thousands are needed. CNC is in the middle somewhere.

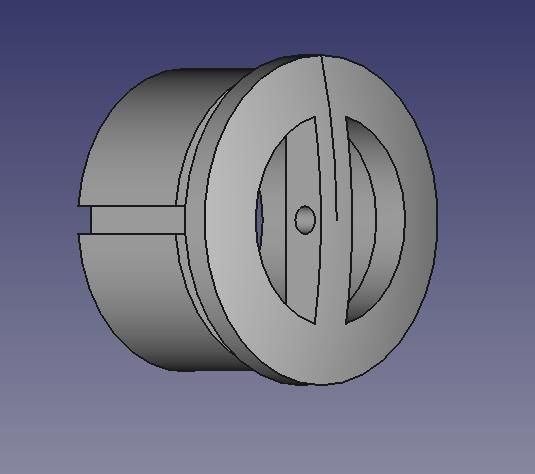

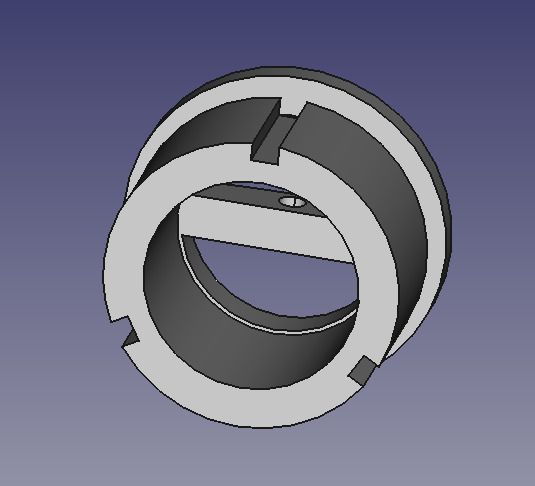

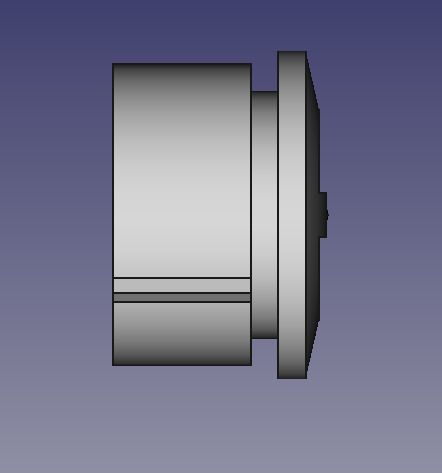

Would be interesting to stage a race at an Exhibition between CAD/CNC and Drawing Board/Pattern/Moulding both starting from the same moderately complicated object drawn from a hat. Like this sink overflow:

Dave

Roderick Jenkins.

Roderick Jenkins.