Posted by Ian Phillips on 01/09/2015 13:43:06:

My indicator mounting is not as bad as you think it is. There is one thumbscrew with a plastic knob but that was tightened by rotating the 12mm square MS bar round it. The indicator end has a HT bolt. Firm-ish finger pressure on the indicator body (far in excess of the overhanging weight) shows a movement of about a couple of thou.

Its true that its not essential to have 360 degrees rotation, when I used the finger type indicator the overhang was much less and I could get full rotation over the saddle. I might go back and use it again or just use partial rotation with less overhang similar to your setup. That way I could eliminate any gravity effects,

If the error was less than 0.001" I would be more than happy but 5 thou is too much (for the present task at least)

Ian P

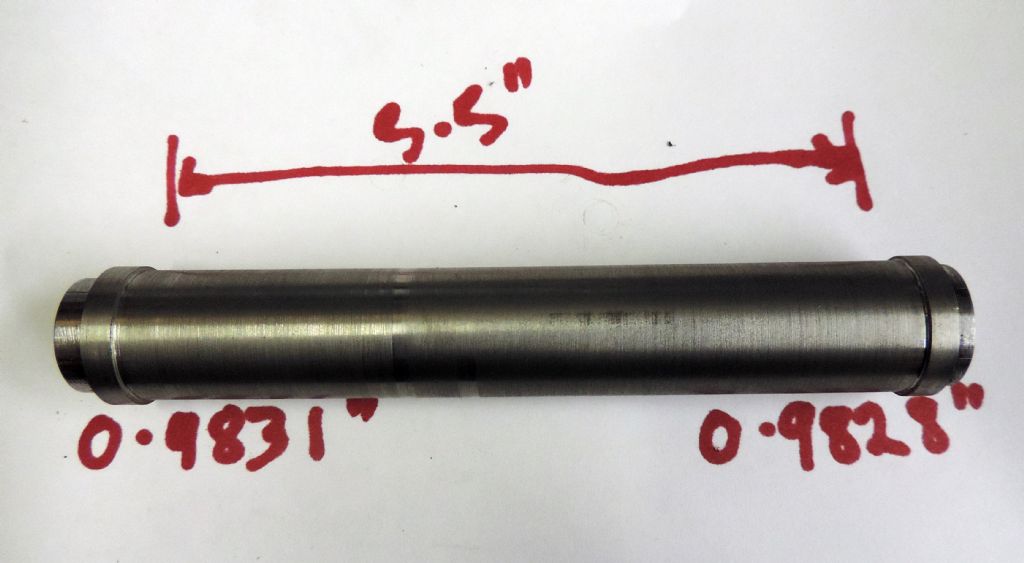

You might be a bit surprised if you put a dial indicator on there that reads in tenths of a thou and see how those long-armed set ups wave about like trees in the wind. Plenty enough to make a difference of a couple of thou, which is basically half the error you are reading of five thou. Believe me. I have been through this, more than once, on machinery ranging from sewing machines to power station turbines. Metal moves more than we think. Even a six-inch long test bar, one inch diameter, held in the chuck at one end can have a sag of more than half a thou at the other.

Yes, going back to using the finger indicator would be a good idea, mounted back close to the chuck on a sturdy bracket.

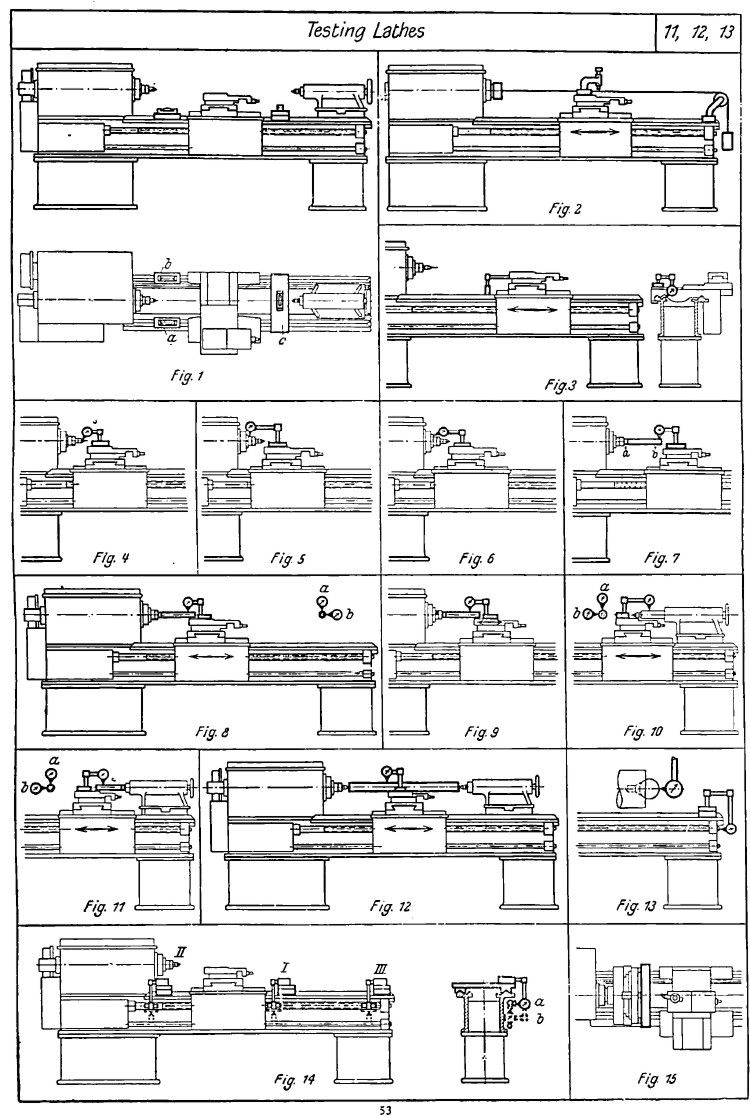

Even if you do decide to remove metal from the tailstock — this is the last in a number of steps to get a lathe running true all over. Before attacking the tailstock with your angle grinder (well flat scraper and rubbing stone maybe), the lathe bed must be set dead level along its full length to eliminate twist and wind. Tricky on a used lathe with worn bed without getting the scrapers out. Then the headstock must be measured for alignment to bed in all directions at operating temperature and corrected if necessary. (or to the tailstock ways on the bed as the case may be). Only then is the tailstock tested and adjusted as needs be. Initial testing on the OD of the quill is ok, but really you need a precision ground morse taper test bar to test both concentricity and angular alignment of the tapered tailstock hole, as well as the height and east-west alignment.

There is little point in lowering the tailstock if the problem is actually bed twist or misaligned headstock that has the headstock spindle axis pointing that five thou above the tailstock axis.

Ian P.

Ian P.