Weary – I think I described this mod on MEM – I recall at least one or two nay sayers doubting the viability of it.

I've had two sets of soft jaws for many years. The first well used and gradually diminishing in material the other still wrapped in their VIP paper.

The first were reclaimed early on by bolting slices of Hexagon bar on each jaw – a good compromise which works well but even the area they were bolted to eventually disappeared. Just about to ditch them and open that new pack I found a short length of about 1 1/2 x 1/2" BMS under the bench.

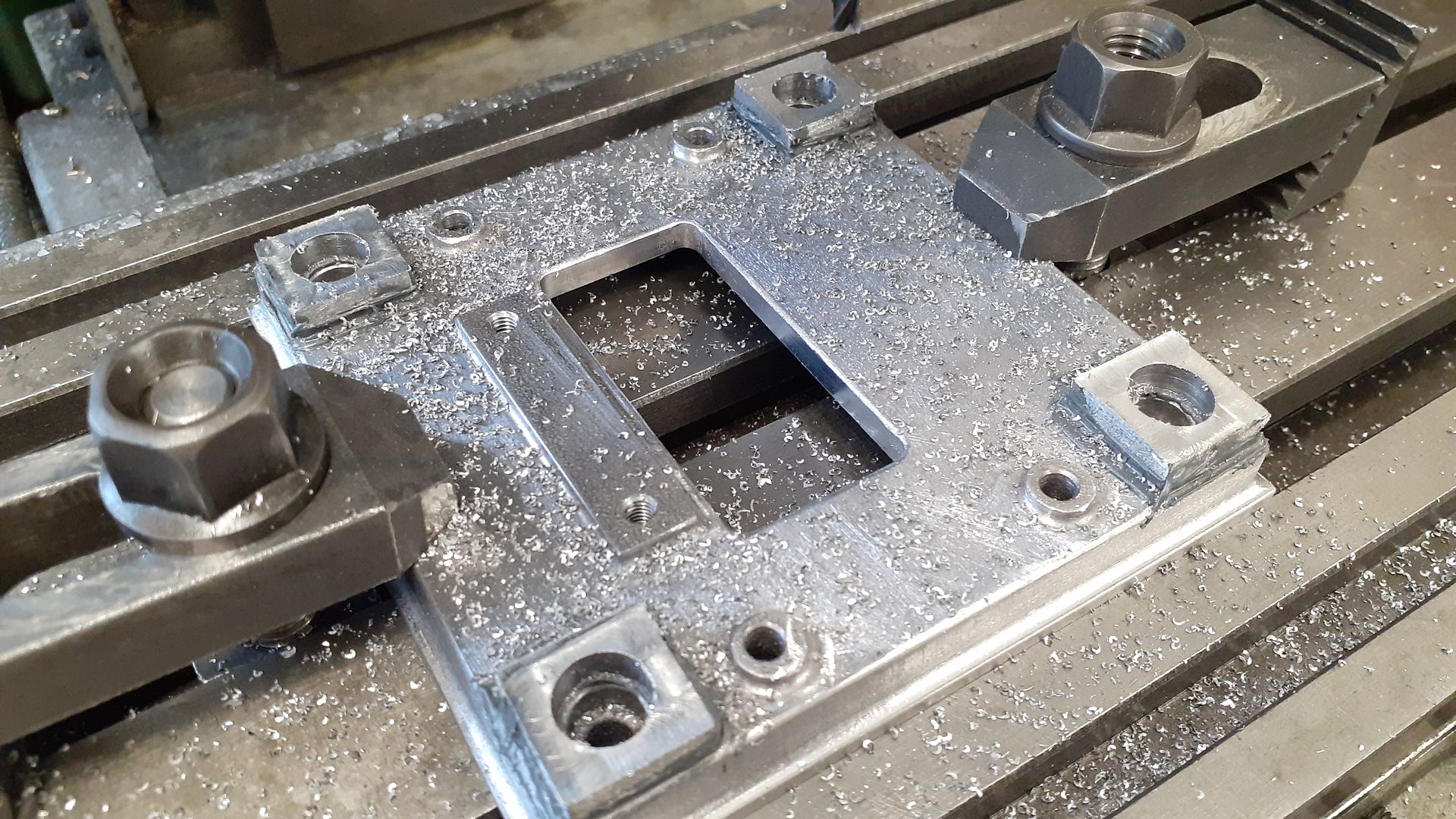

It was cut it into three lengths then a deep slot was machined in each jaw and each piece just JB welded in place without any pinning or bolting. It was left a few days to cure right through before using.

I think this was testing it – the embryo liner for an IC engine

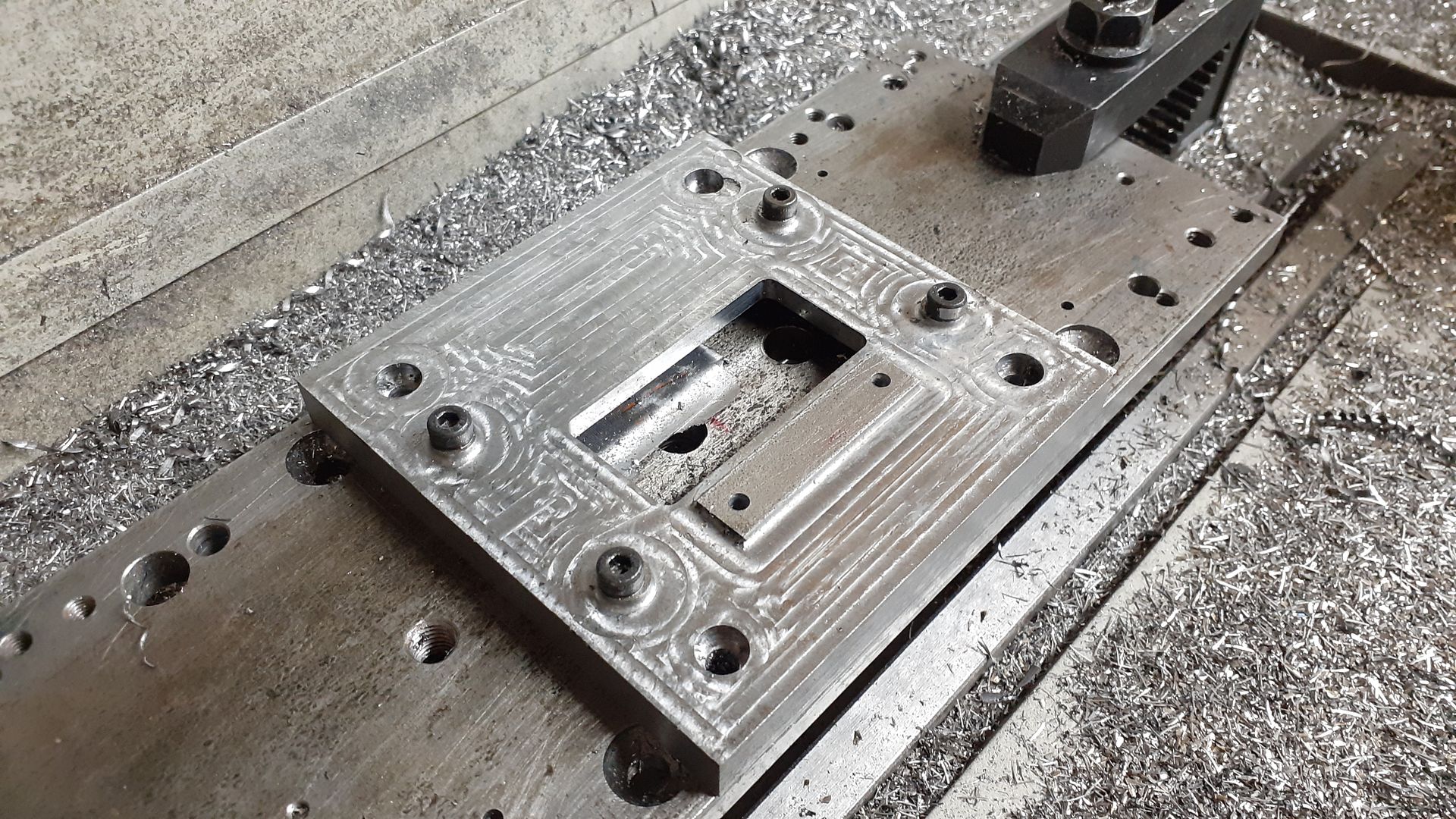

They have been in regular use since though at one point well into it's life I thought I felt a movement, a slight give on tightening. No, must have been me as they are still in use though closely reaching another reclaim I fear.

Despite the fears of the nay sayers, the inserts have not parted company in use and have saved quite a useful accessory not to mention the cost if replacement was required.

Yep JB Weld is a useful tool to have on the bench alright

Tug

Edited By Ramon Wilson on 20/11/2022 18:16:56

Ian Skeldon 2.