Just bear in mind scale, average parquet is about 3" wide so that is going to be less than 1/8" wide at the scale of this engine not lolly widths.

So given the recent posts about preparing stock and a sequence to make the parts I hop eyou are sitting comfortably.

Preparing stock.

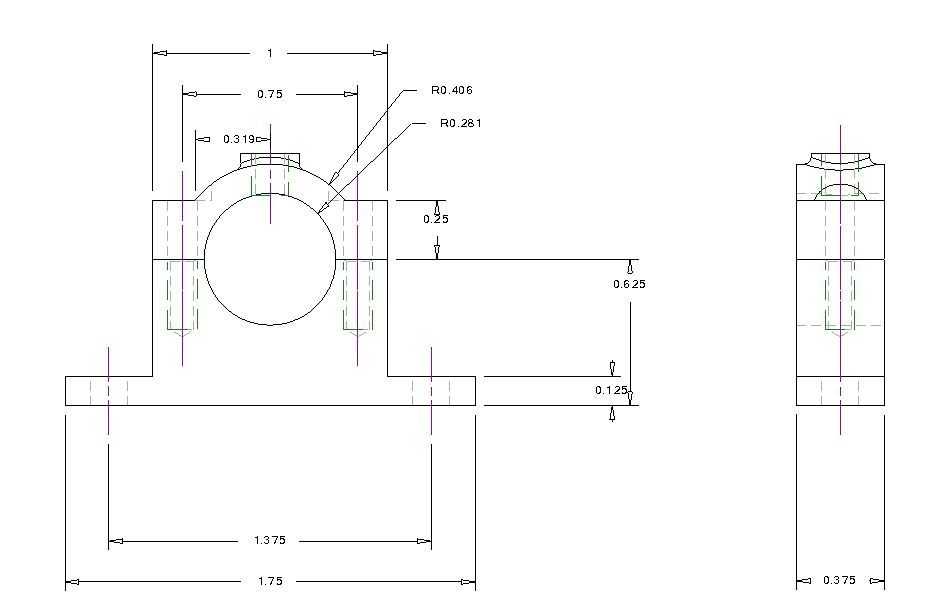

After sawing up and deburring four pieces of your 1/2" bar you will be ready to go.

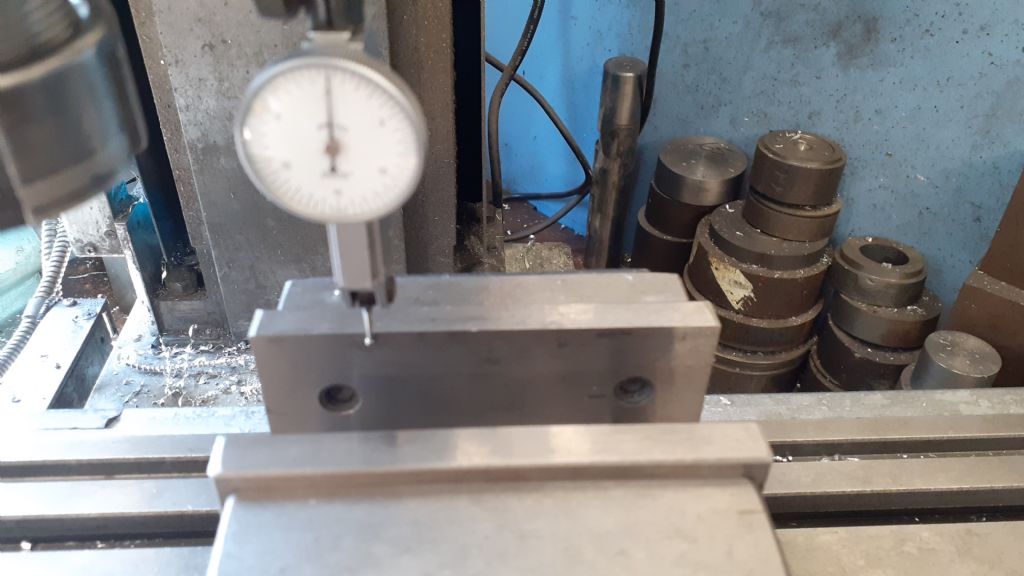

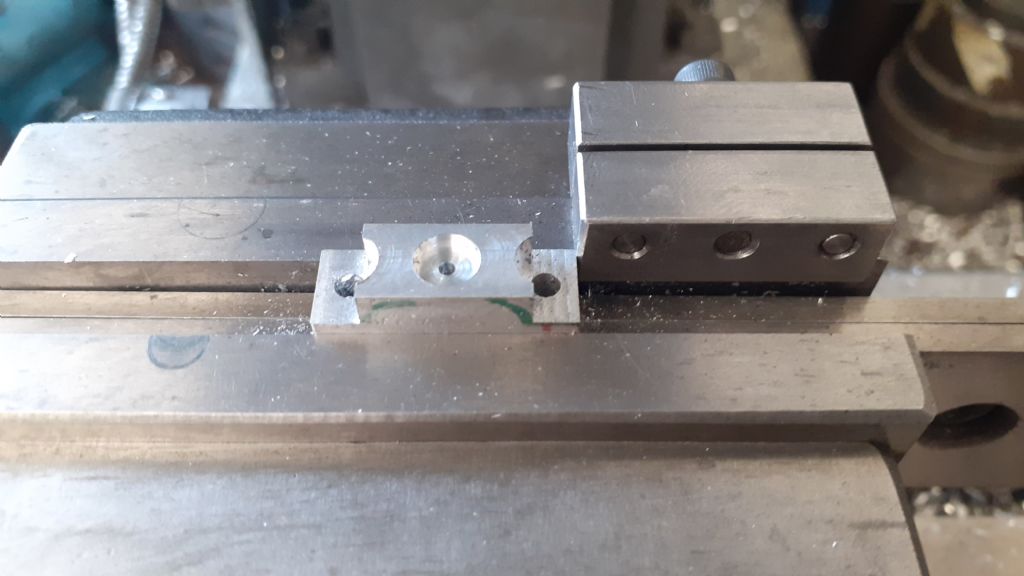

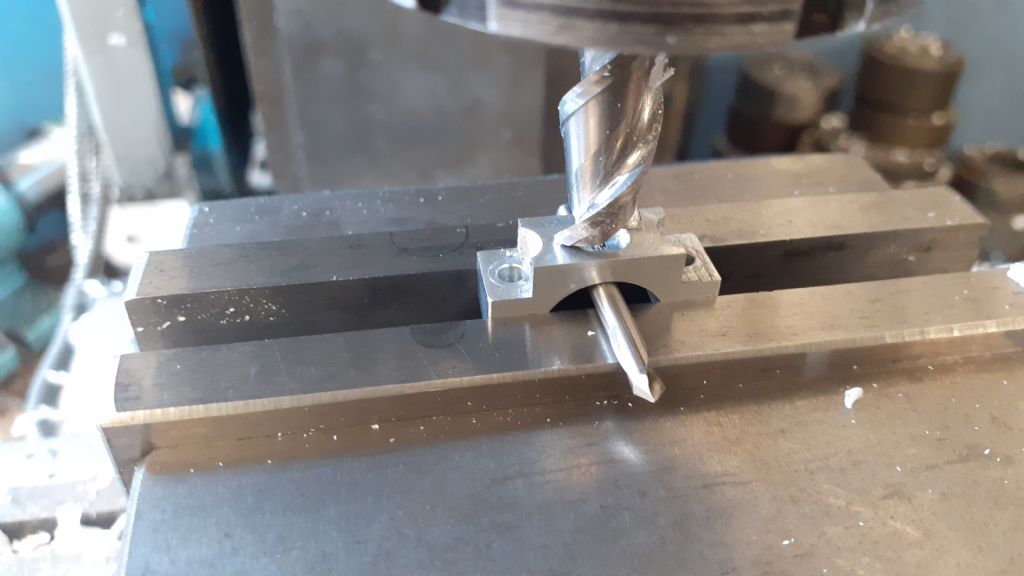

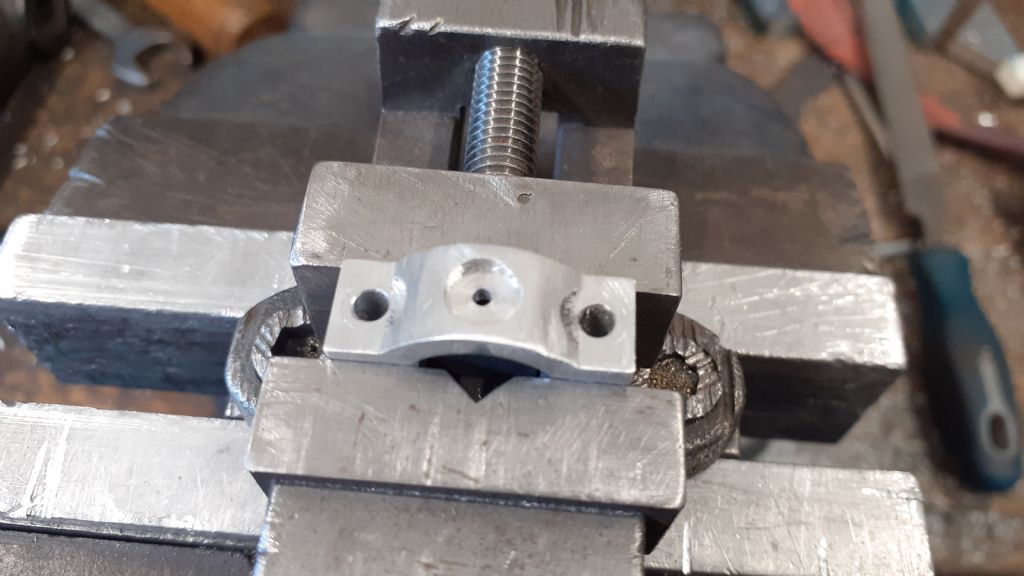

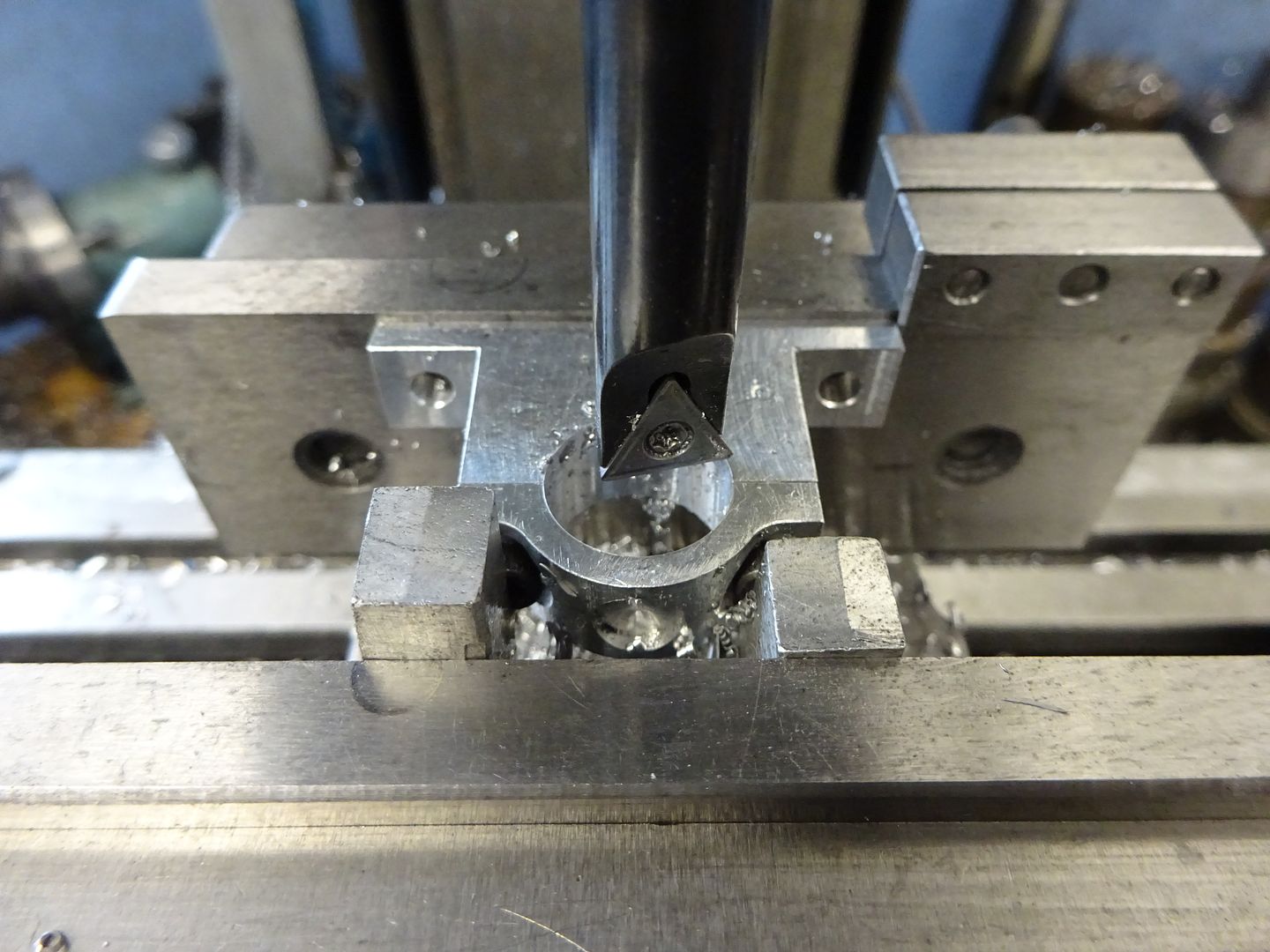

Start by making sure your vices fixed jaw is clocked true in X as that will be our ref face, I assume the base of the vice is parallel to the mill table.

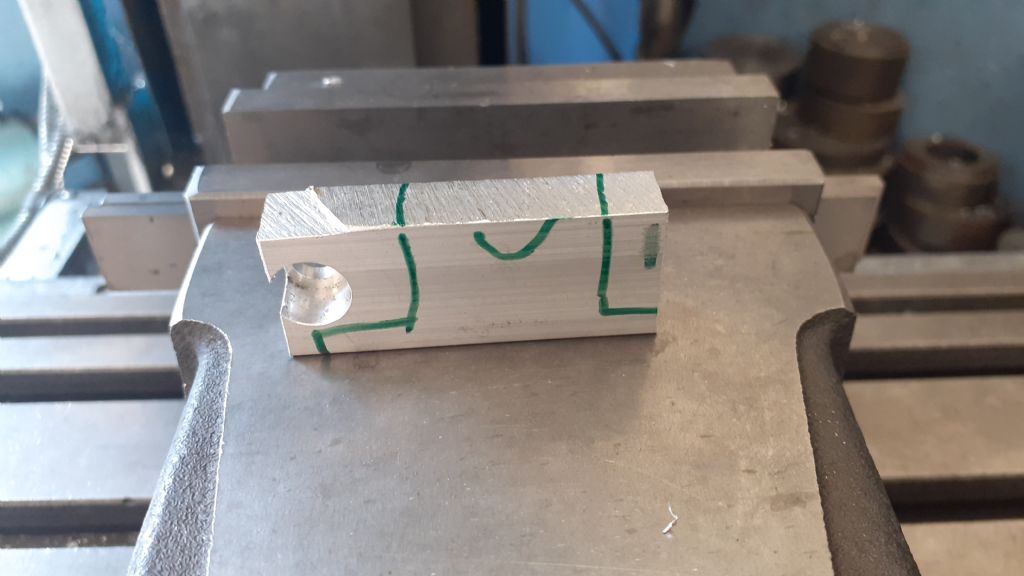

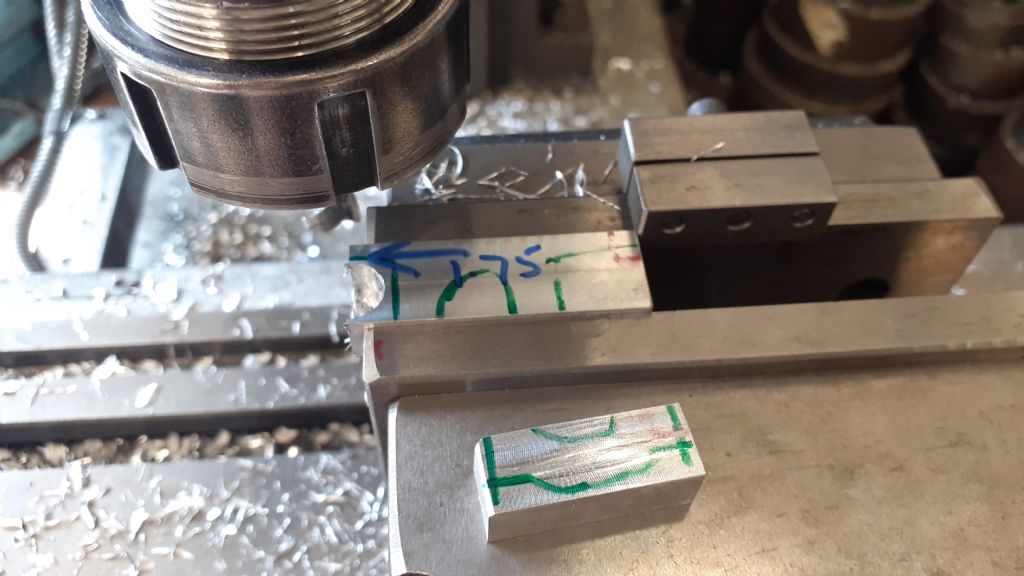

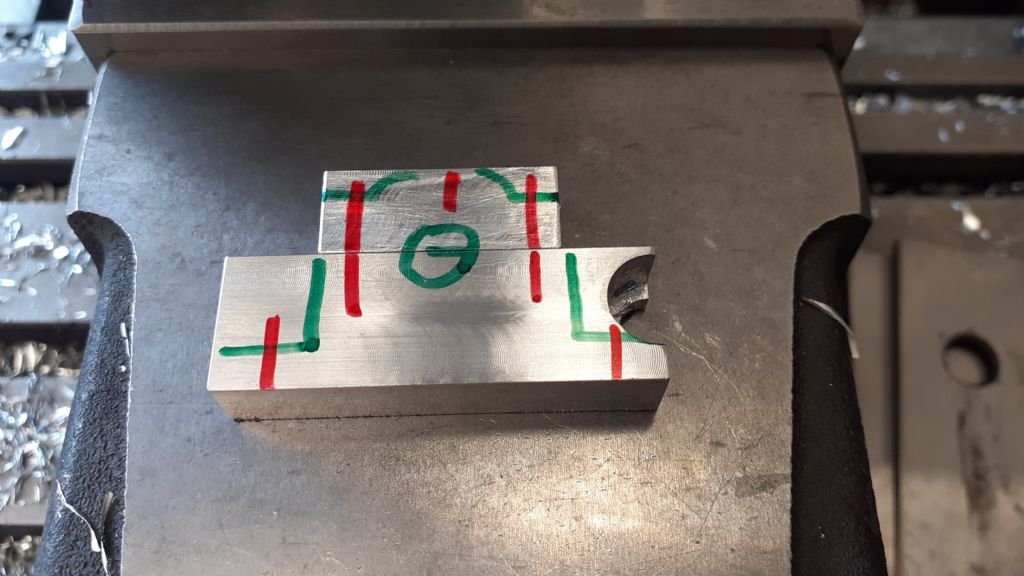

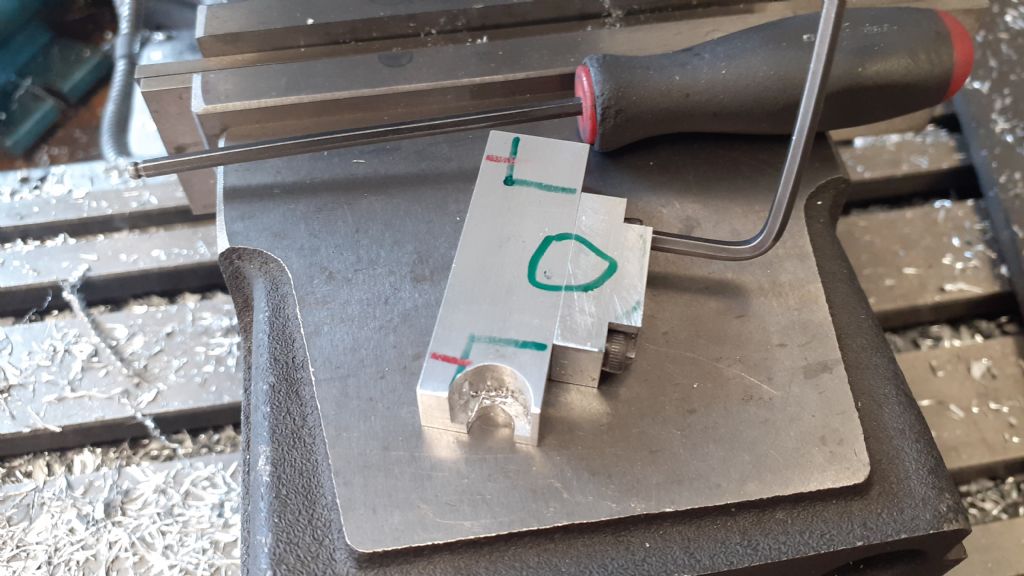

A few sharpie marks will help to keep track of what is to come off where, I'm using an offcut and may later regret leaving that hole. I'm just going to make one but repeat each stage for the other before moving on to the next.

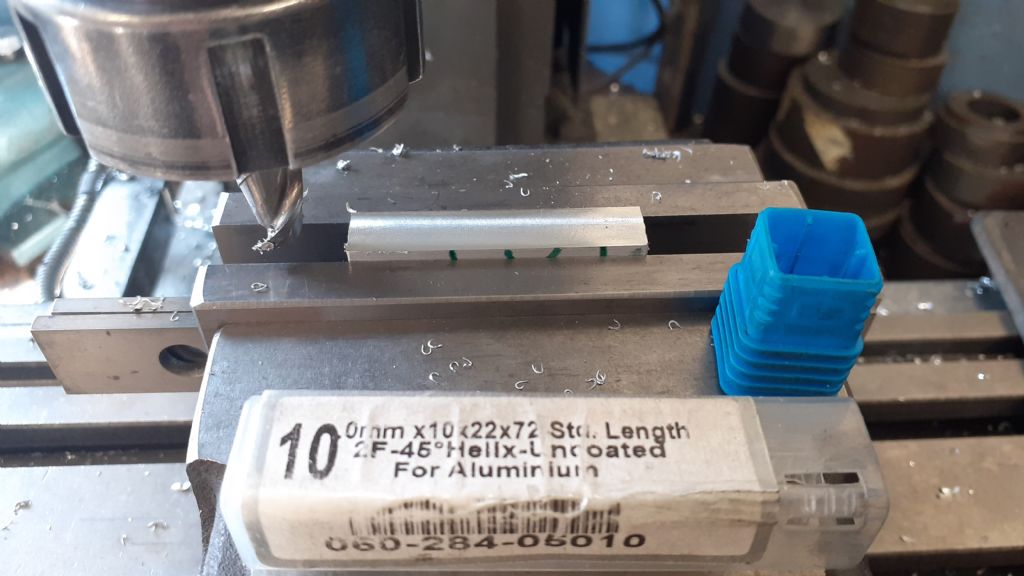

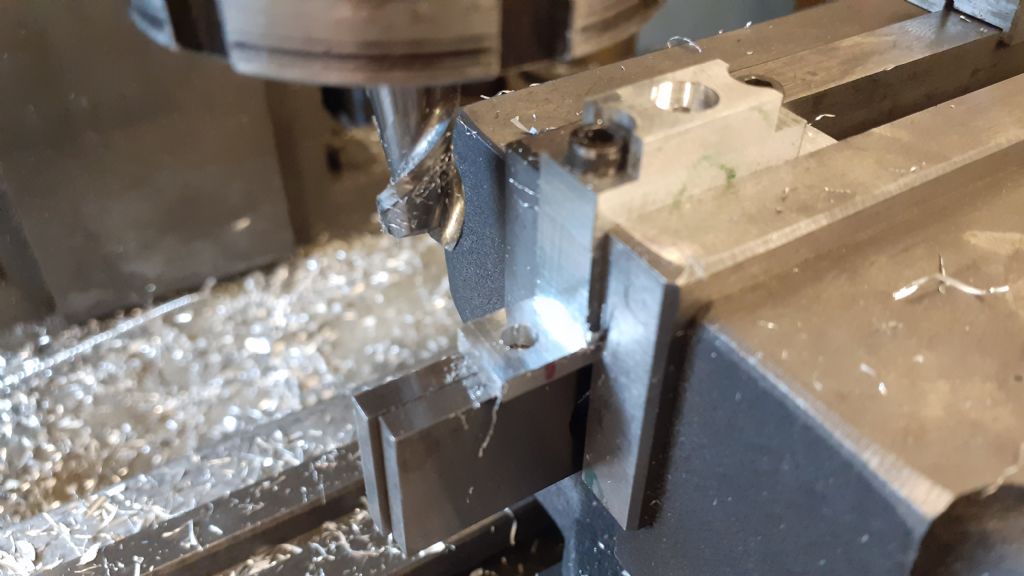

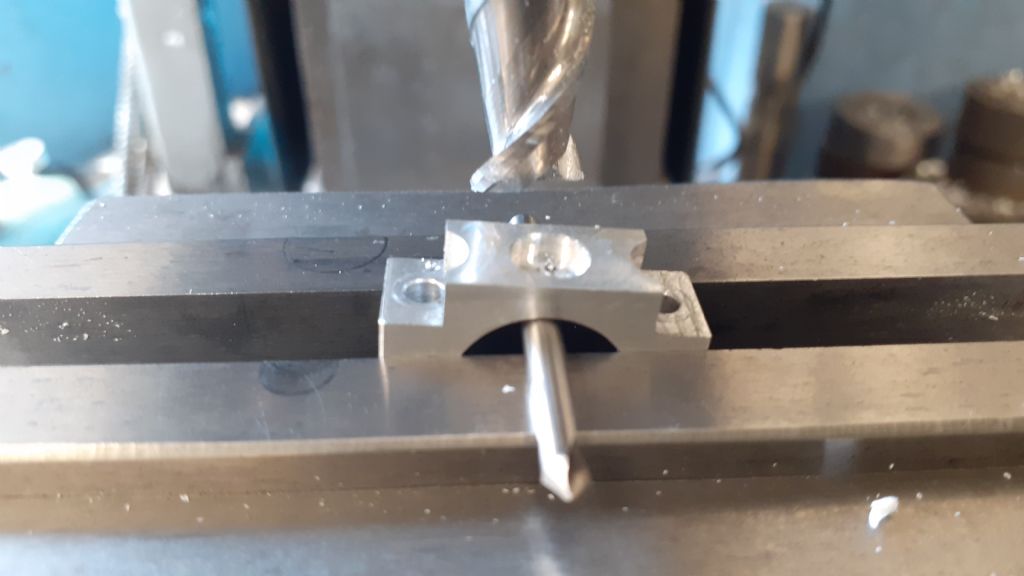

As the two half inch faces are parallel we can make use of them to go against the vice jaws, rest the base stock on some parallels, tighten vice and tap down then take a cut over the sawn surface to clean it up. I'm using a 10mm 2-flute cutter specific for non ferrous.

remove from vice and deburr then rotate 190 deg keeping the marked face to you and mill the opposite face to the required 0.625".

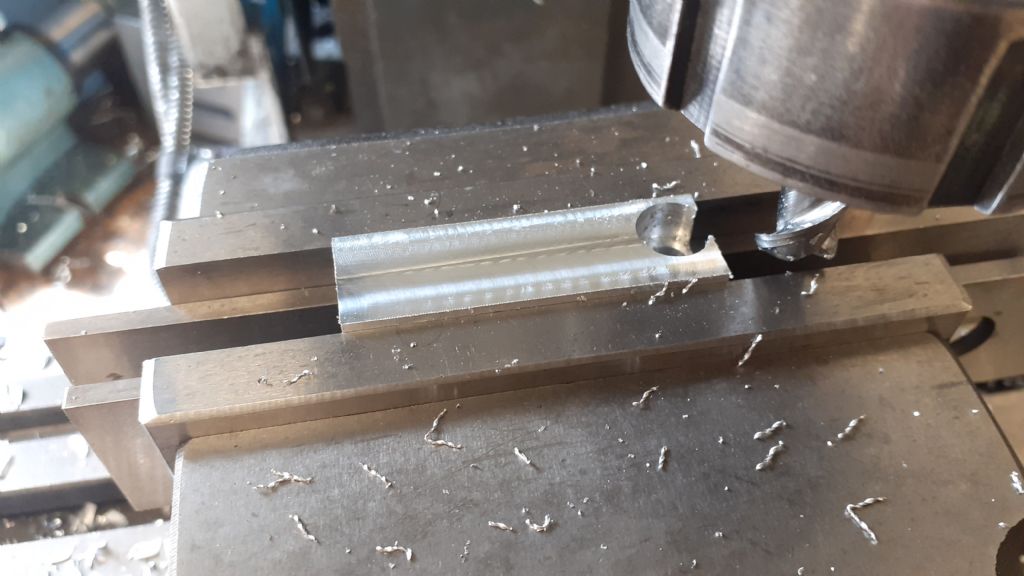

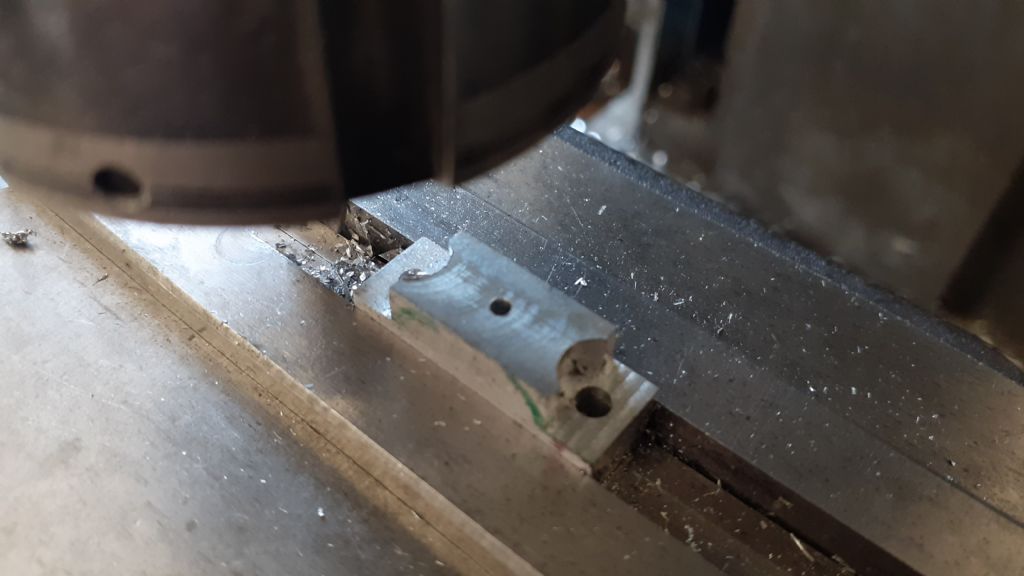

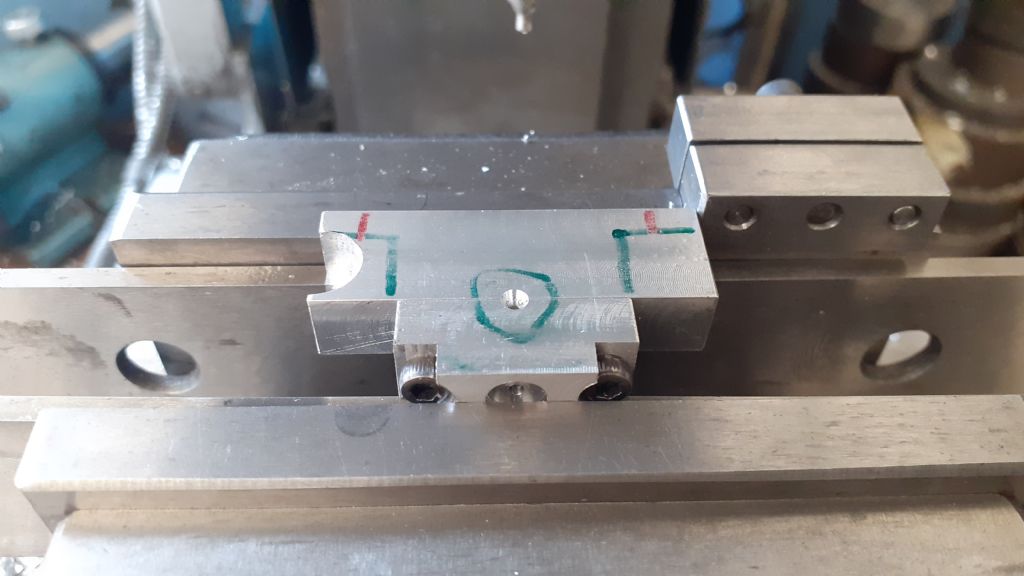

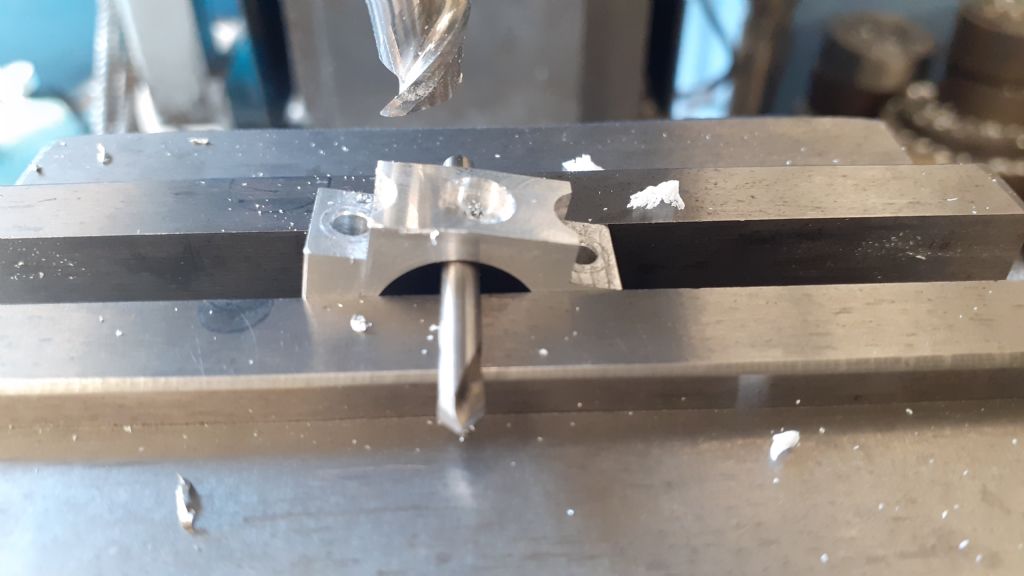

We now have the two thin edges machined and parallel so they can now be used to hold the work while the thickness is brought down to 0.375", start by taking approx 1/16" off the first face

Then after deburring replace the other way up so the remaining material can come off the second face

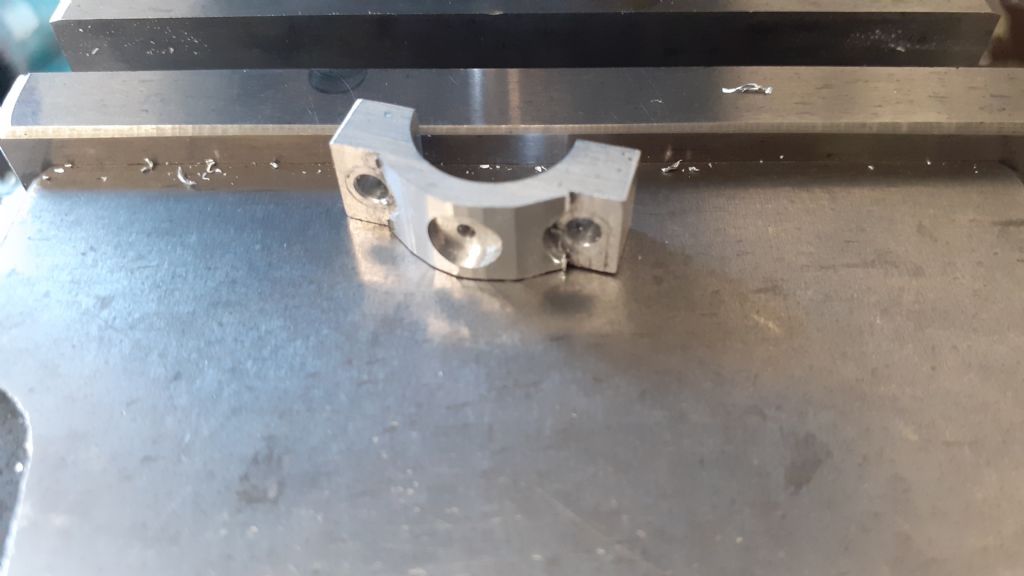

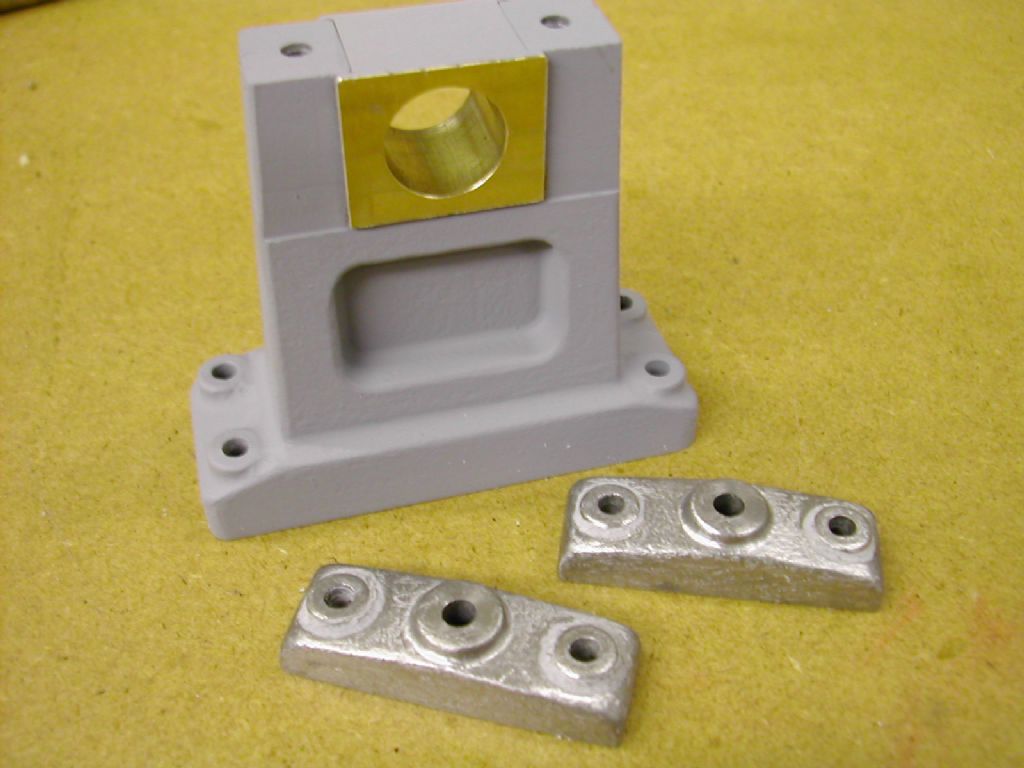

Go through the same process on the material for the caps then you have four pieces of the correct cross section.

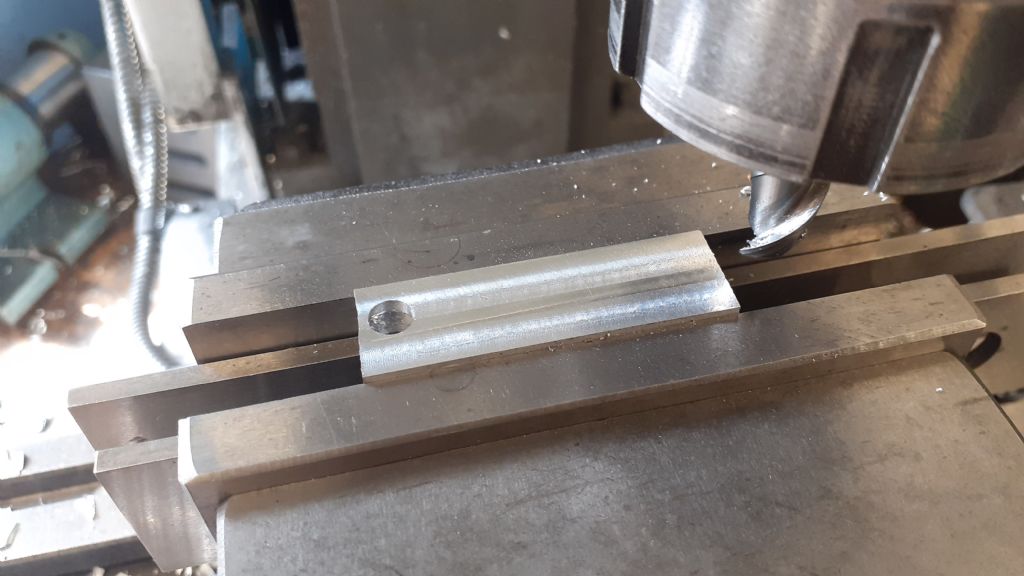

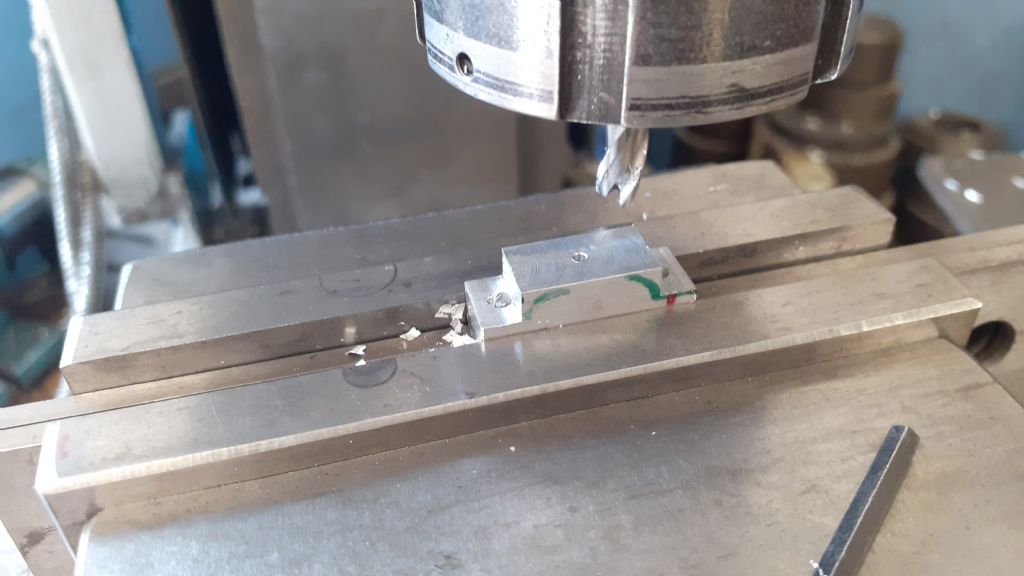

Next stage is to skim a little off one end of each piece to give a square end, full height cuts about 0.25mm per pass.

Set up the vice stop and then set the part with the squared end against the stop and machine to final length, 1.75" for the lower half, 1" for the caps

Time for a refresh of the sharpie marks then I'll carry on in a second post

JasonB.

JasonB.

![20220715_165735[1].jpg 20220715_165735[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/911358.jpg)