Having followed a couple of Sanjay’s threads on MEM about his enclose Stuart engines and a recent discussion on here I found this topic had moved up towards the top of my “future projects” list. The final straw was an article in the German MiM magazine about the restoration of an MTB 1B. So I had to get making one.

Sometime 100-115yrs ago Stuart introduced the MTB 1B as a replacement for the No1 MTB and that is what my engine is based on, in particular one from towards the end of the production period. These engines were intended as high speed power plants for model boats and the MTB stands for Model Torpedo Boat which was a popular hull type of the period often using flash steam and being able to reach 4000rpm.

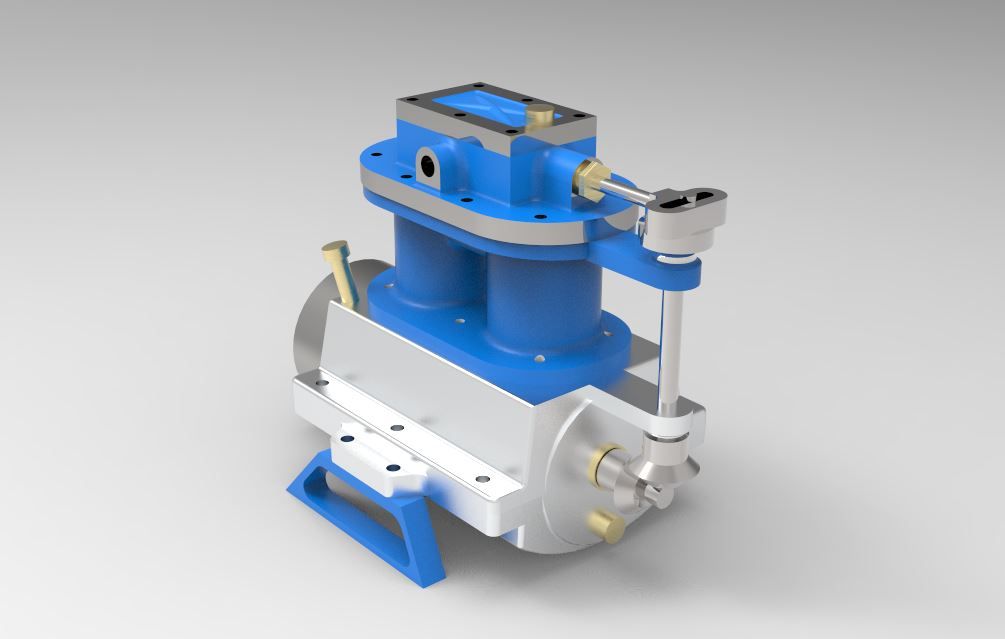

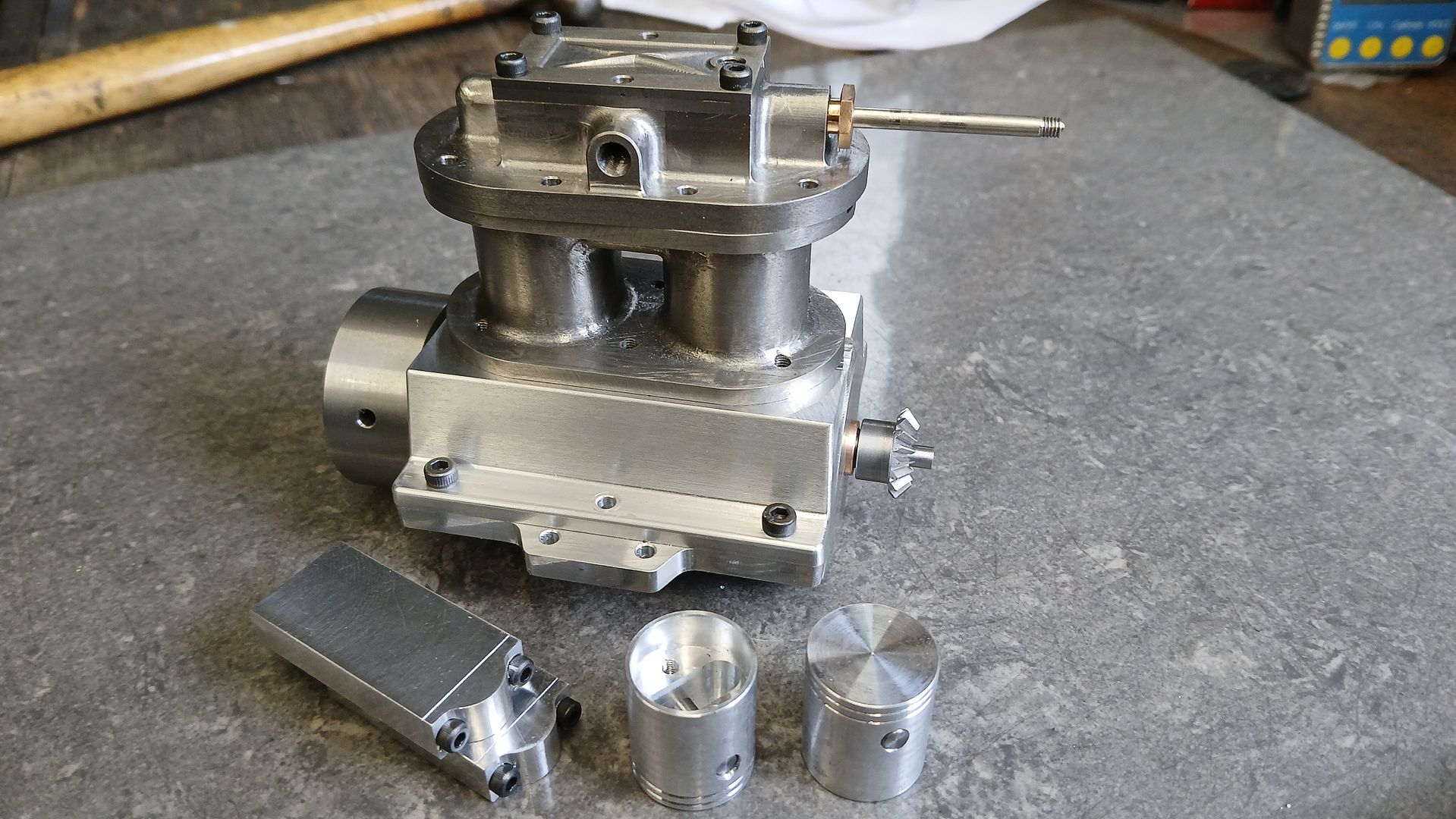

I have made a few changes to the original design mostly due to not starting with castings and the main ones are. Drawn up as usual in Alibre

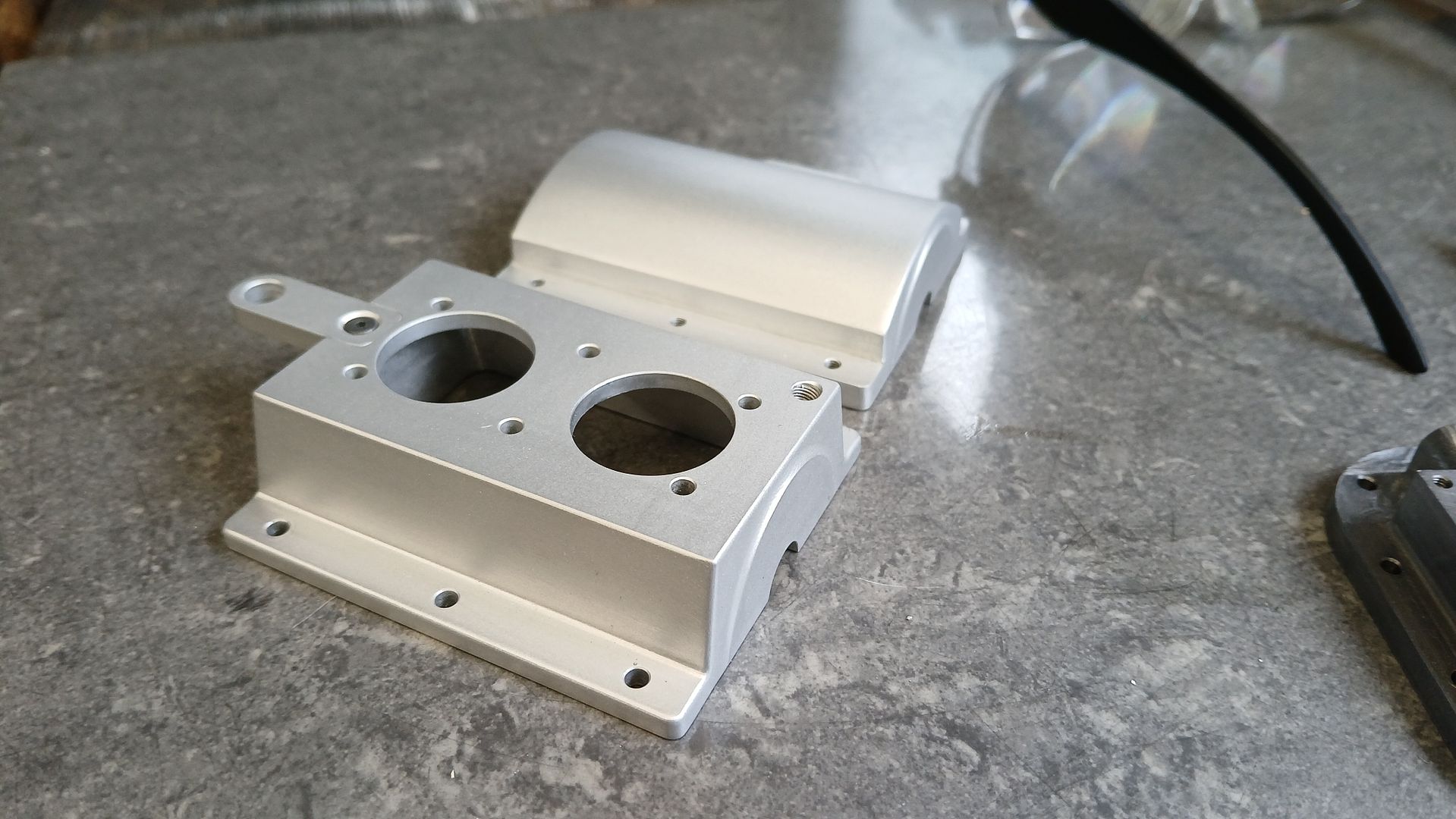

-Aluminium crankcase rather than iron which was actually an option with the MTB 1A “featherweight”

– Separate cylinder “casting” as the original had it cast integral with the top half of the crankcase, this was mainly to save turning so much metal into swarf.

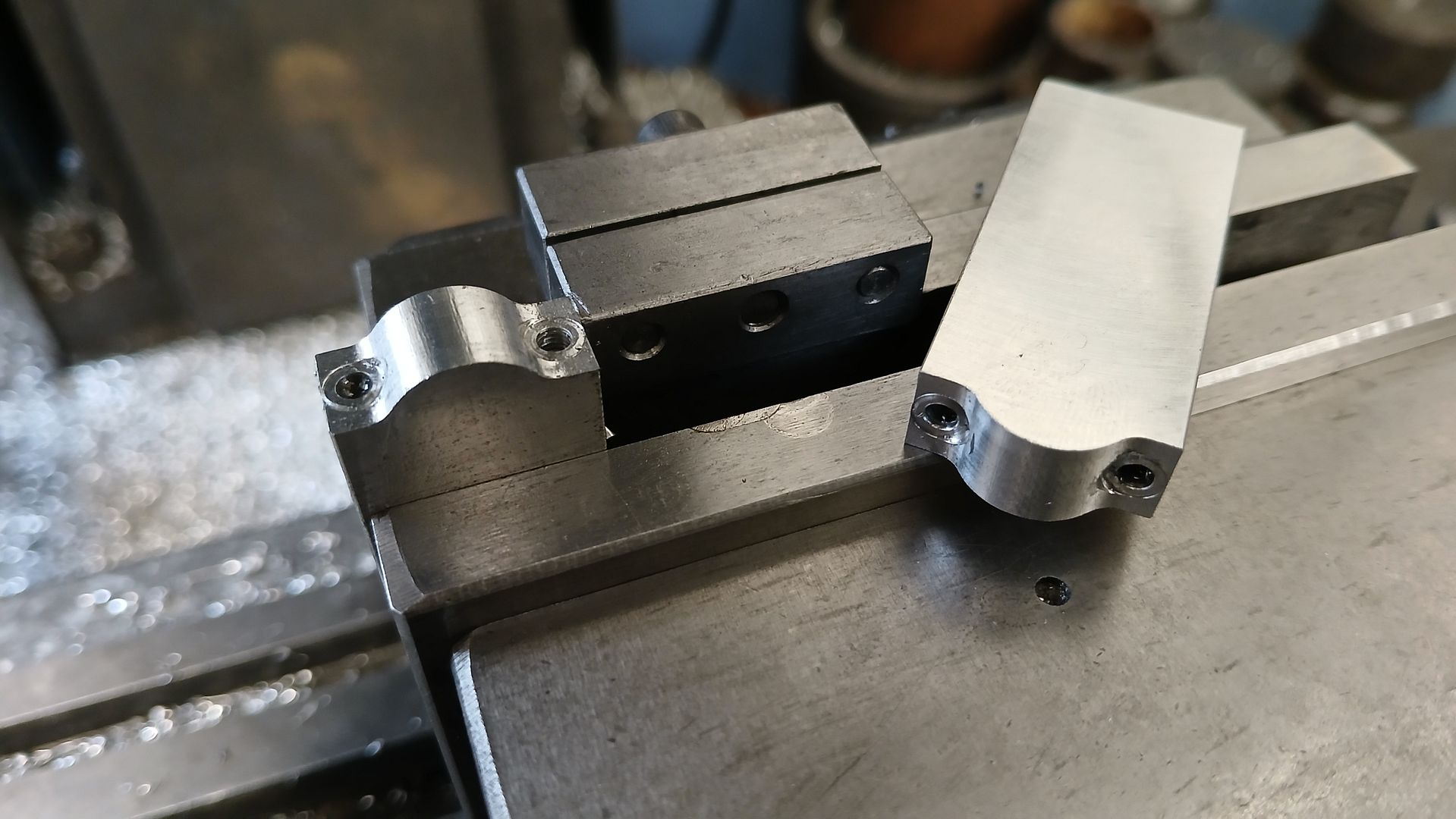

– Bronze crankshaft bearings due to the aluminim crankcase where as the orininal ran straight in the iron casting.

– Probably not going to have cladding on the cylinder which was “russian iron” as I like the look of the engine without and you do see quite a few surviving examples like this.

– Although mine will be a 1:1 size replica it will be done in metric using whole dimensions not just a direct mathmatical conversion so the 3/4″ bore x 3/4″ stroke is 19mm x 19mm dead. This is also why I have named my version the 1M for metric.

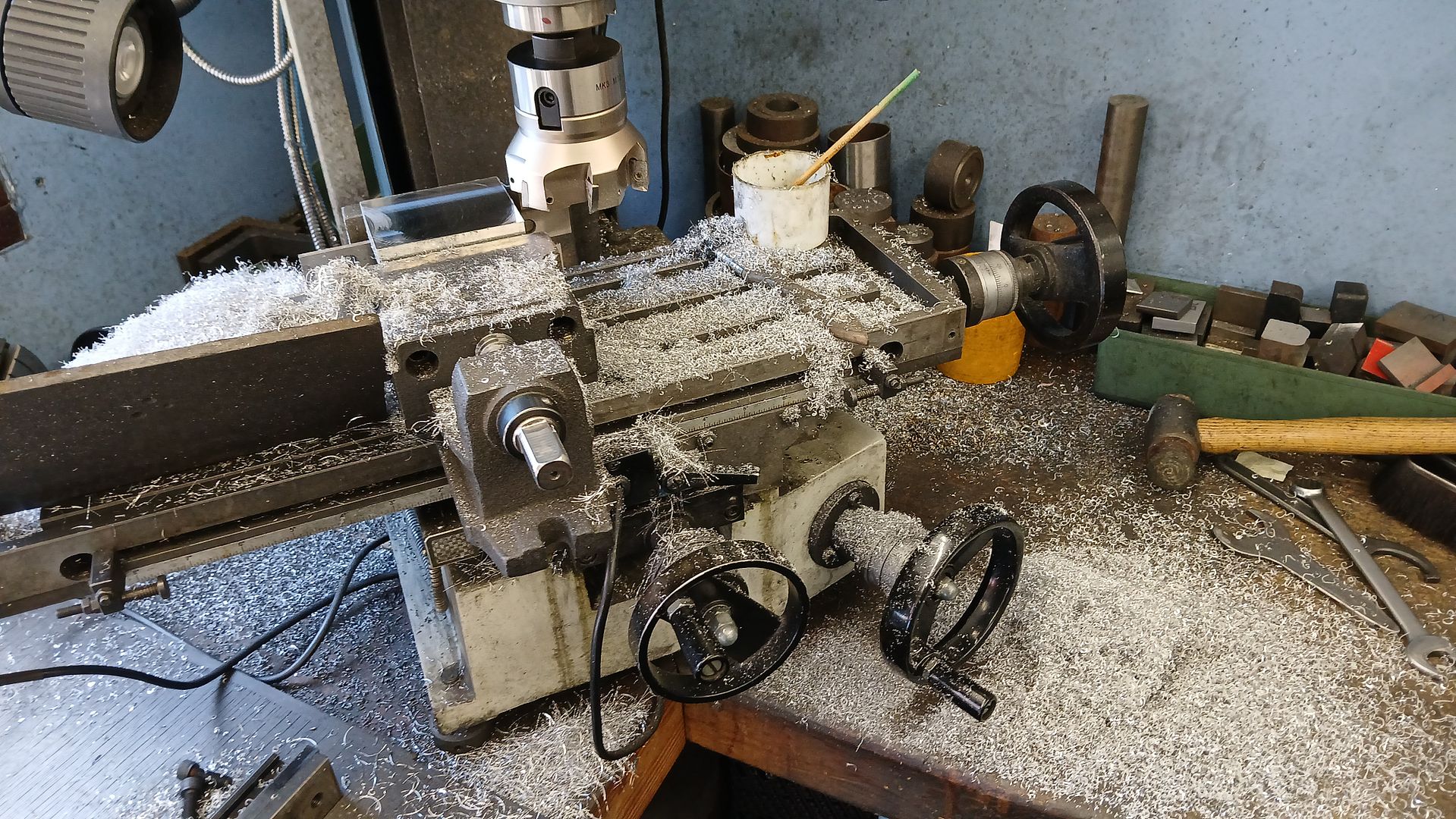

Although the main “casting” on this one will have a fair bit of CNC work I probably won’t do as much video of that like I did for the previous A J Weed engine as it is much the same unless anyone asks.

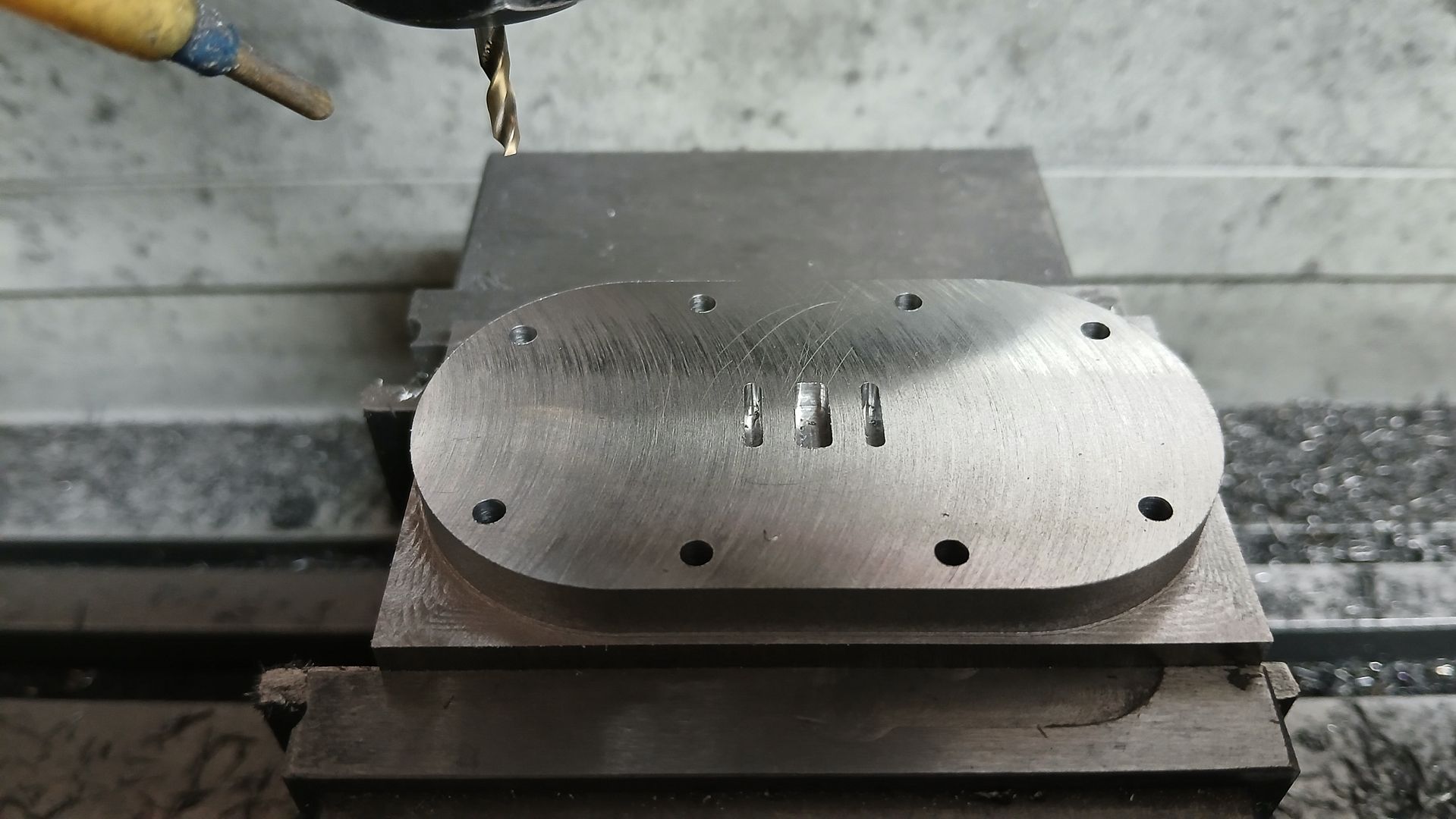

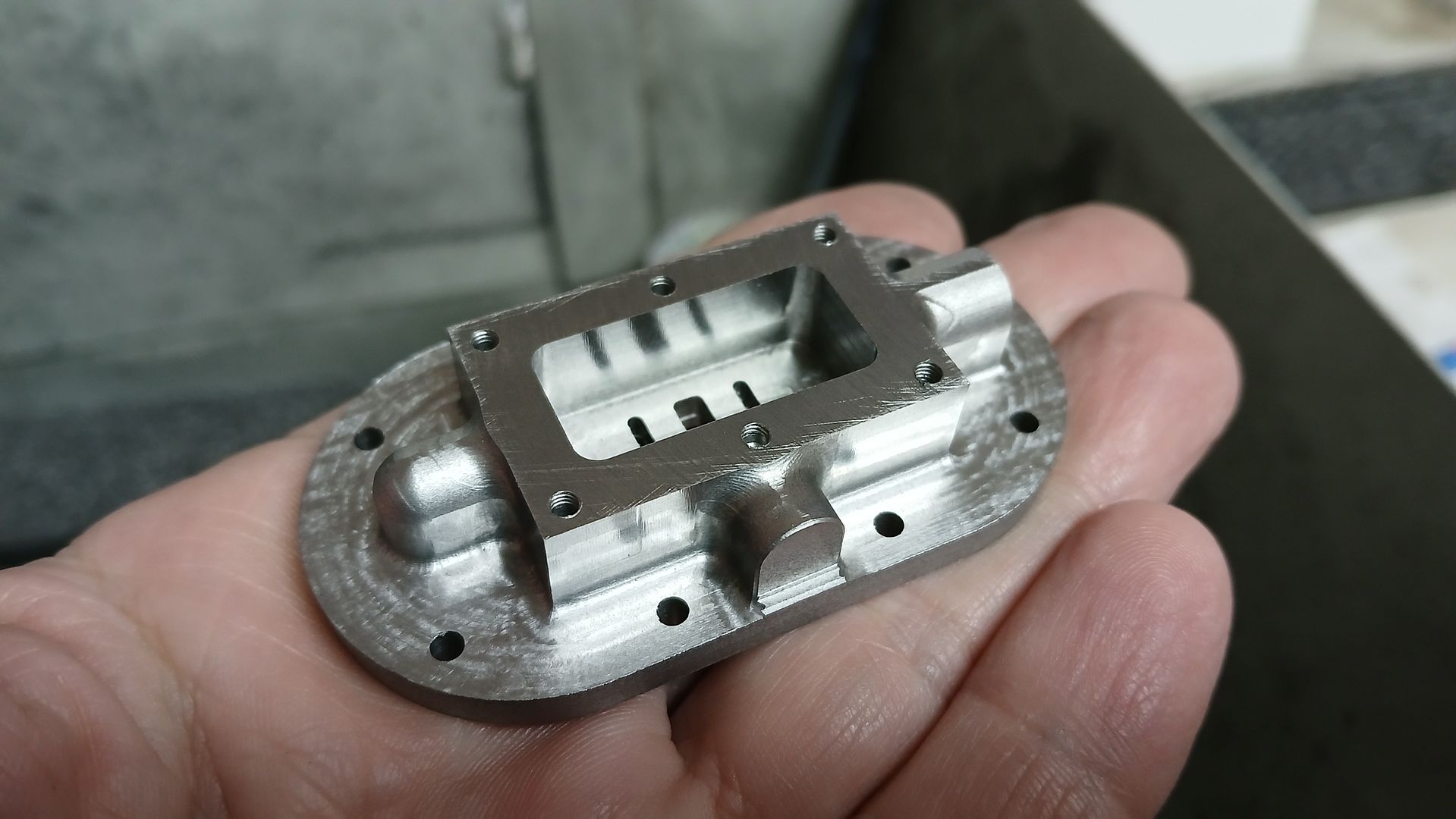

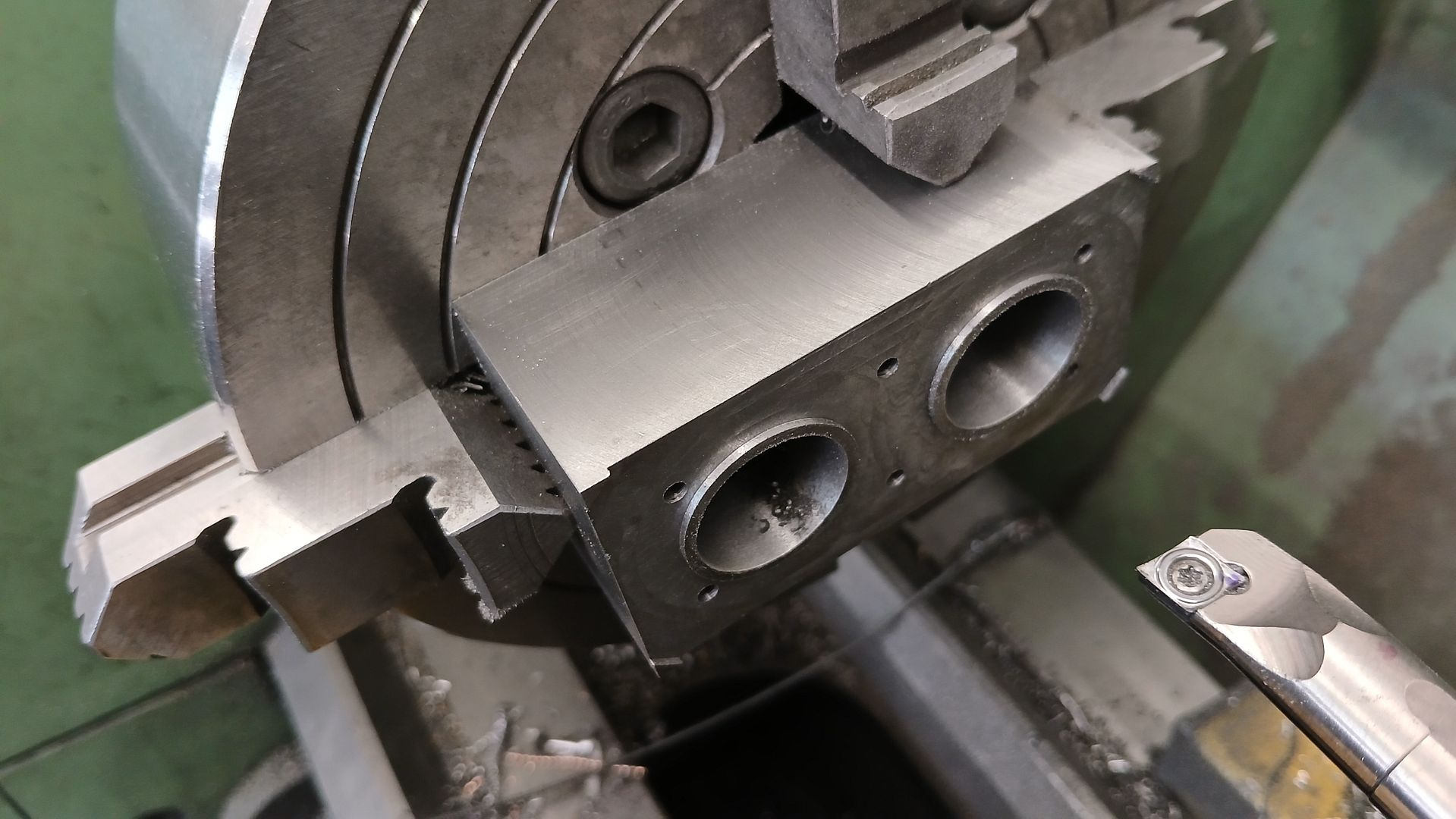

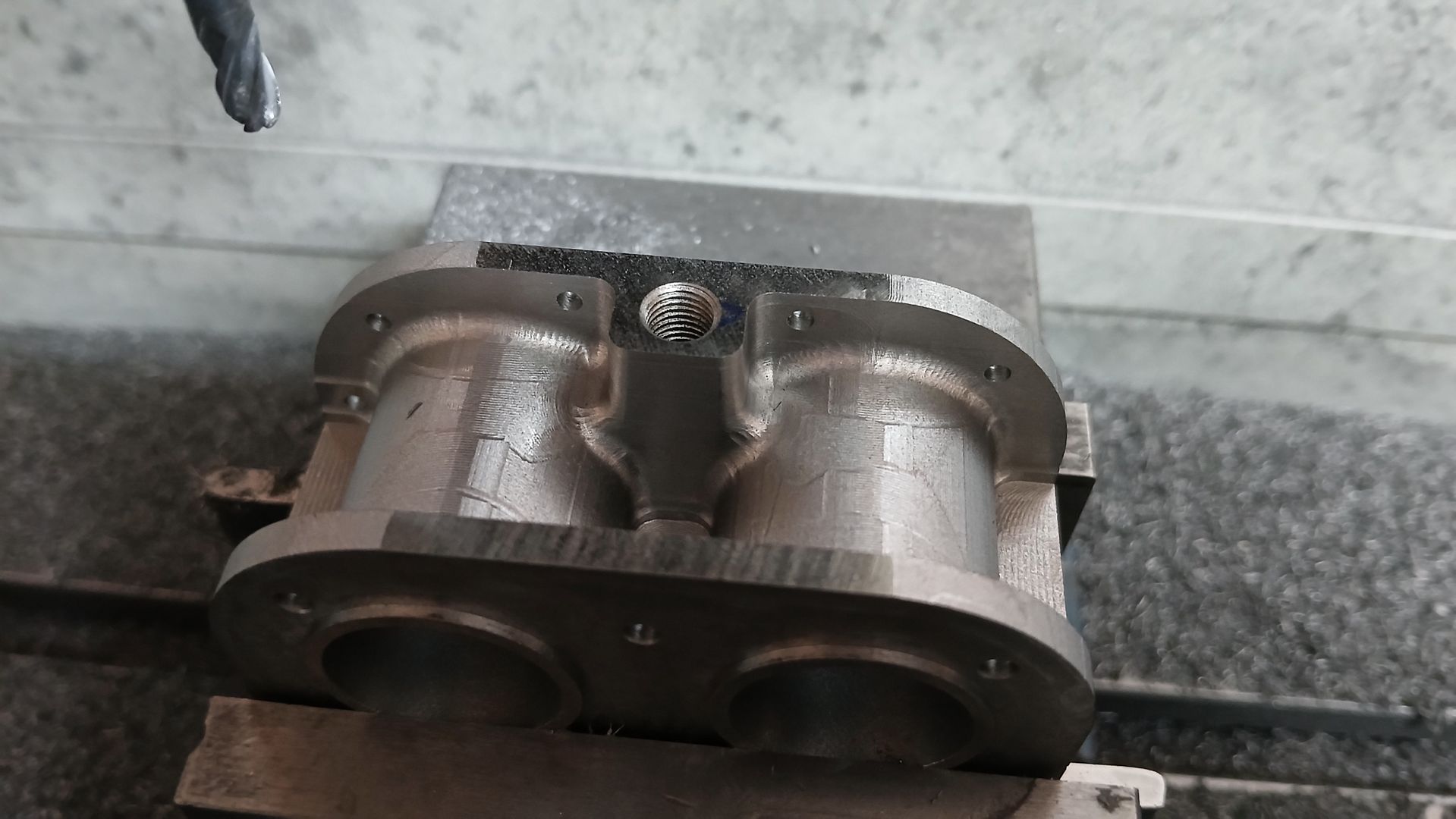

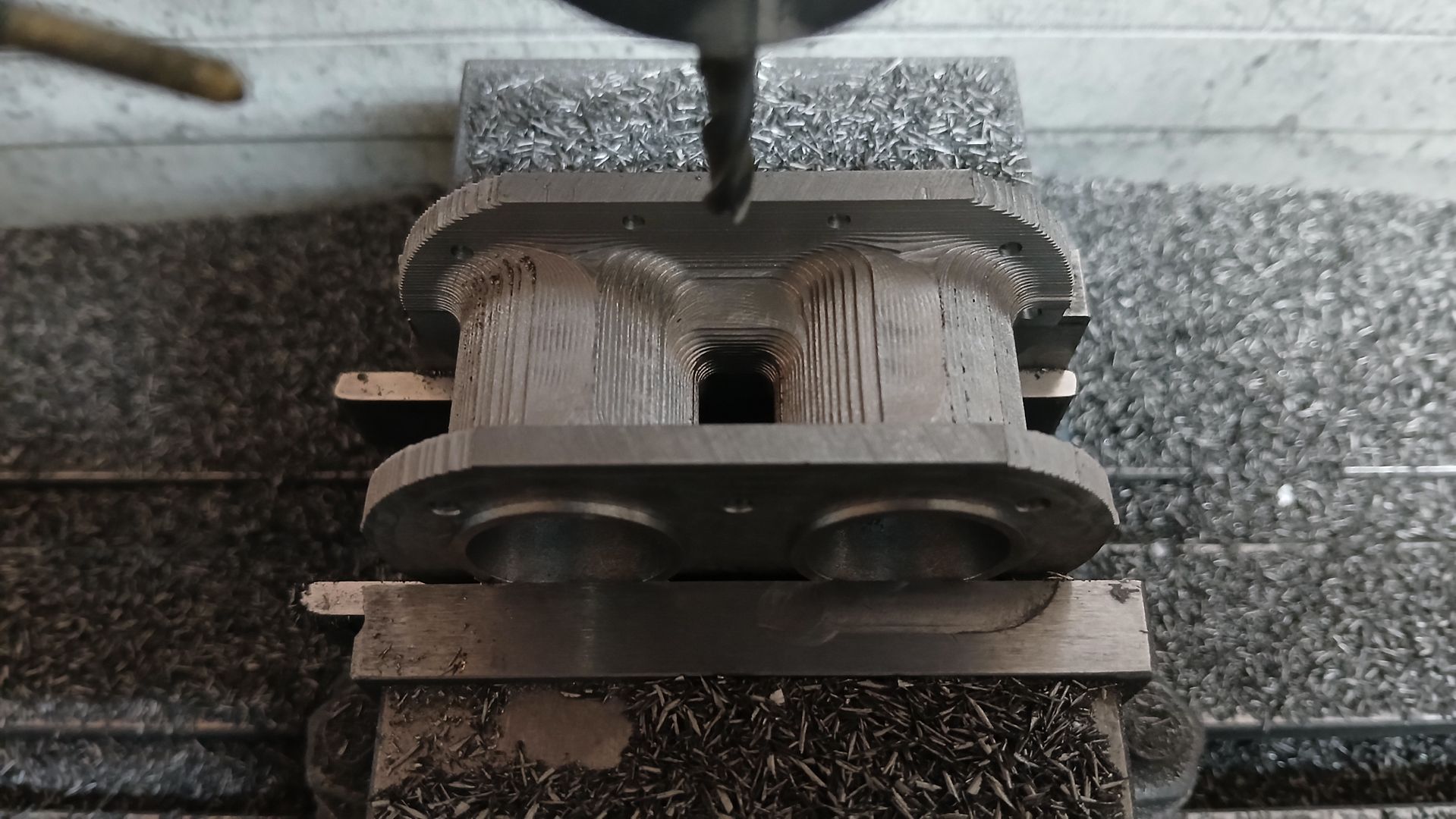

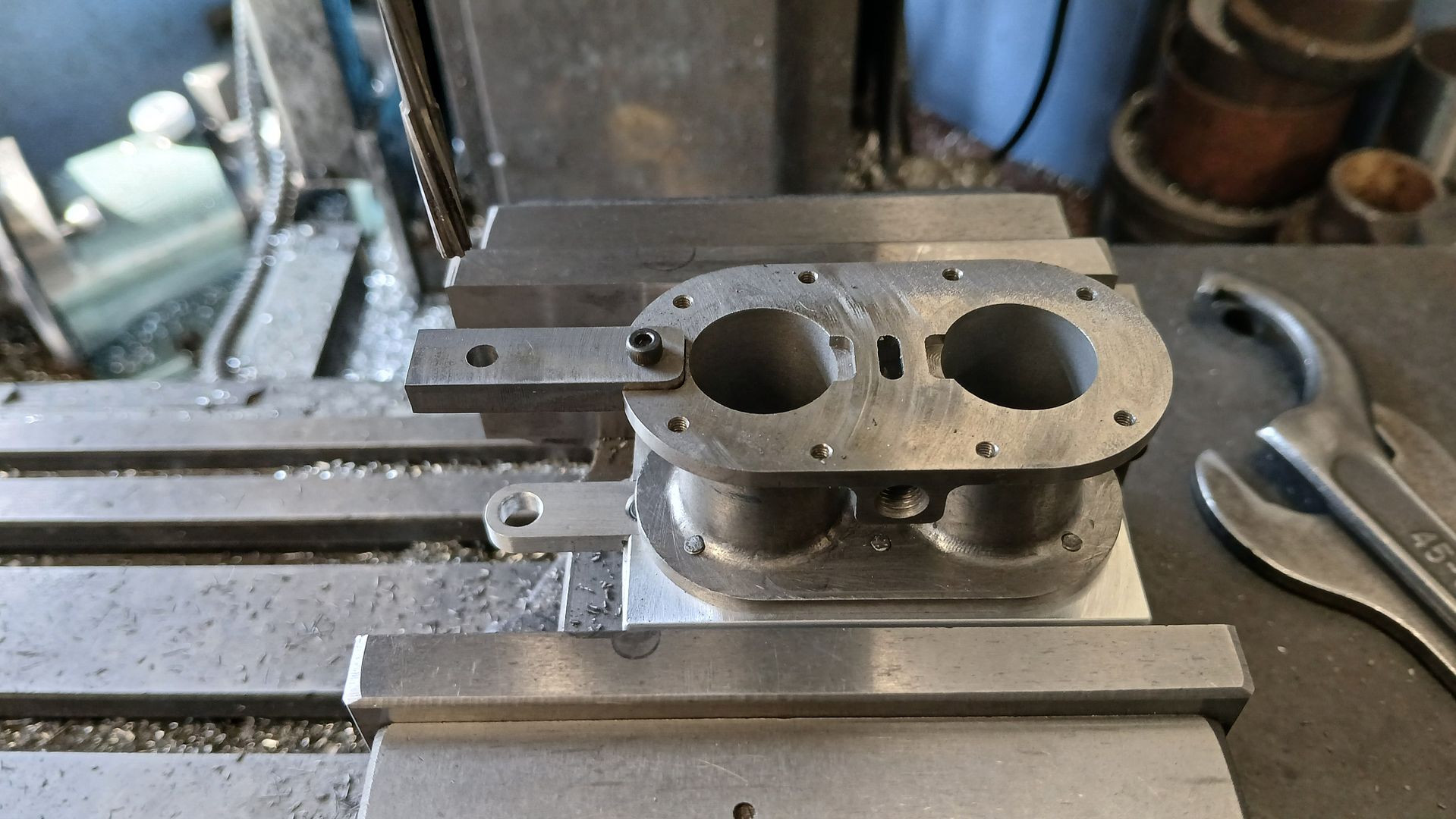

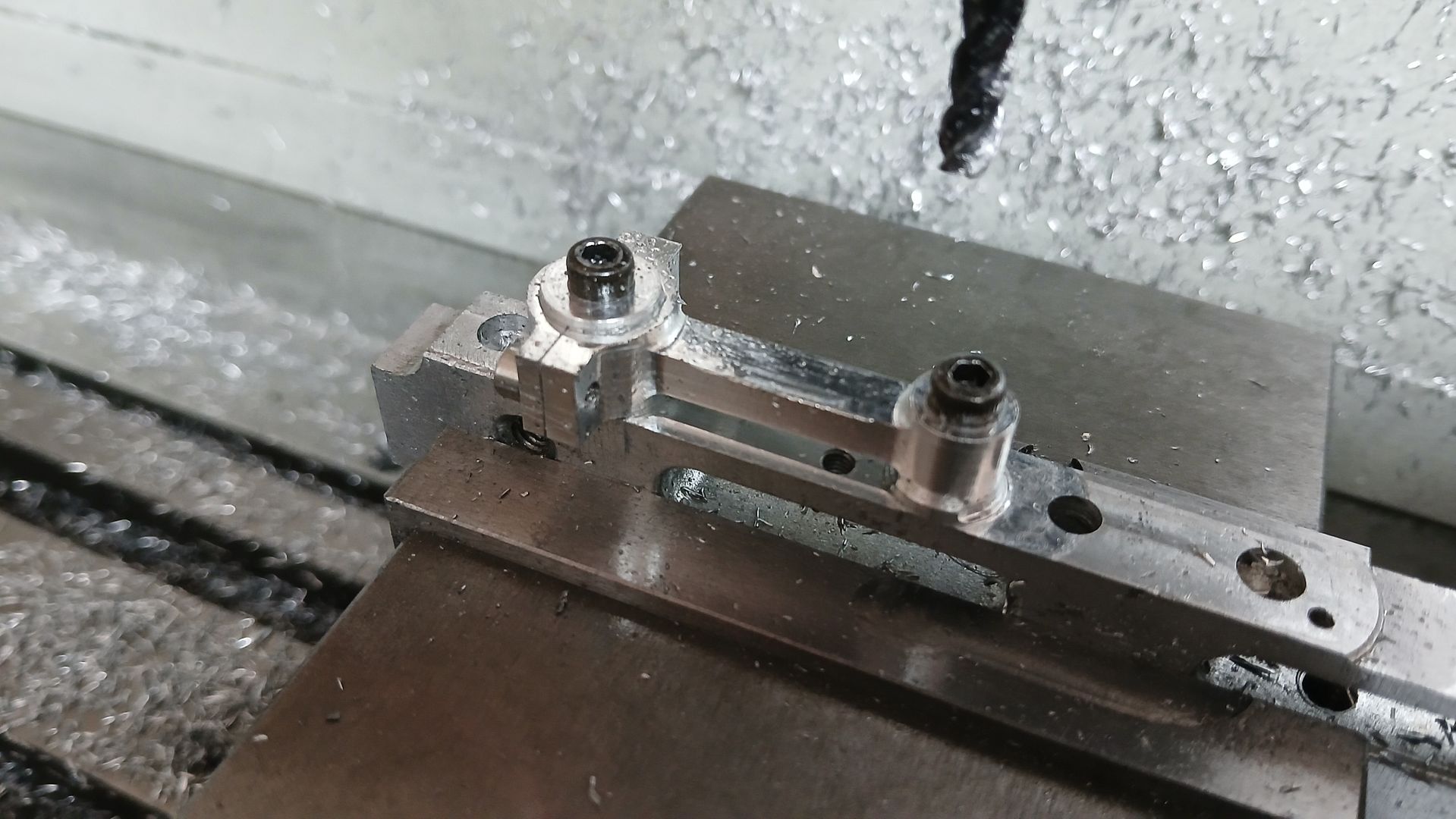

For a change I started towards the top of this one with what could be called the cylinder head come valve chest. After sawing off and cleaning up a block of cast iron it was held upside down so that the bottom oval shape could be machined, various screw holes added and also the steam passages cut half way through. It was the first time I have done these on the CNC and it certainly reduces the bum clenching as it just works it’s way back and forth in a slowly descending zigzag path producing the 1.5mm wide slots with ease.

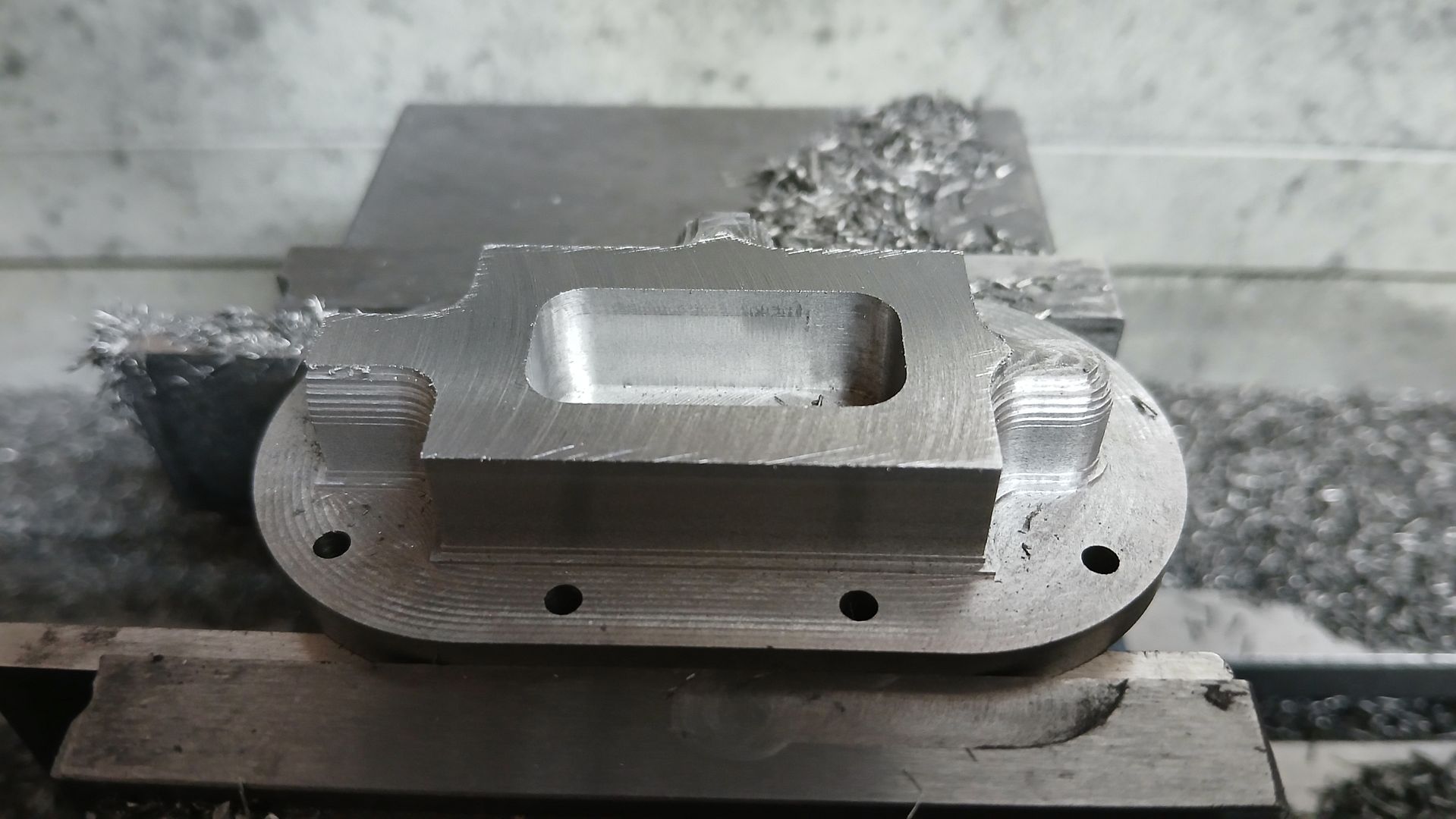

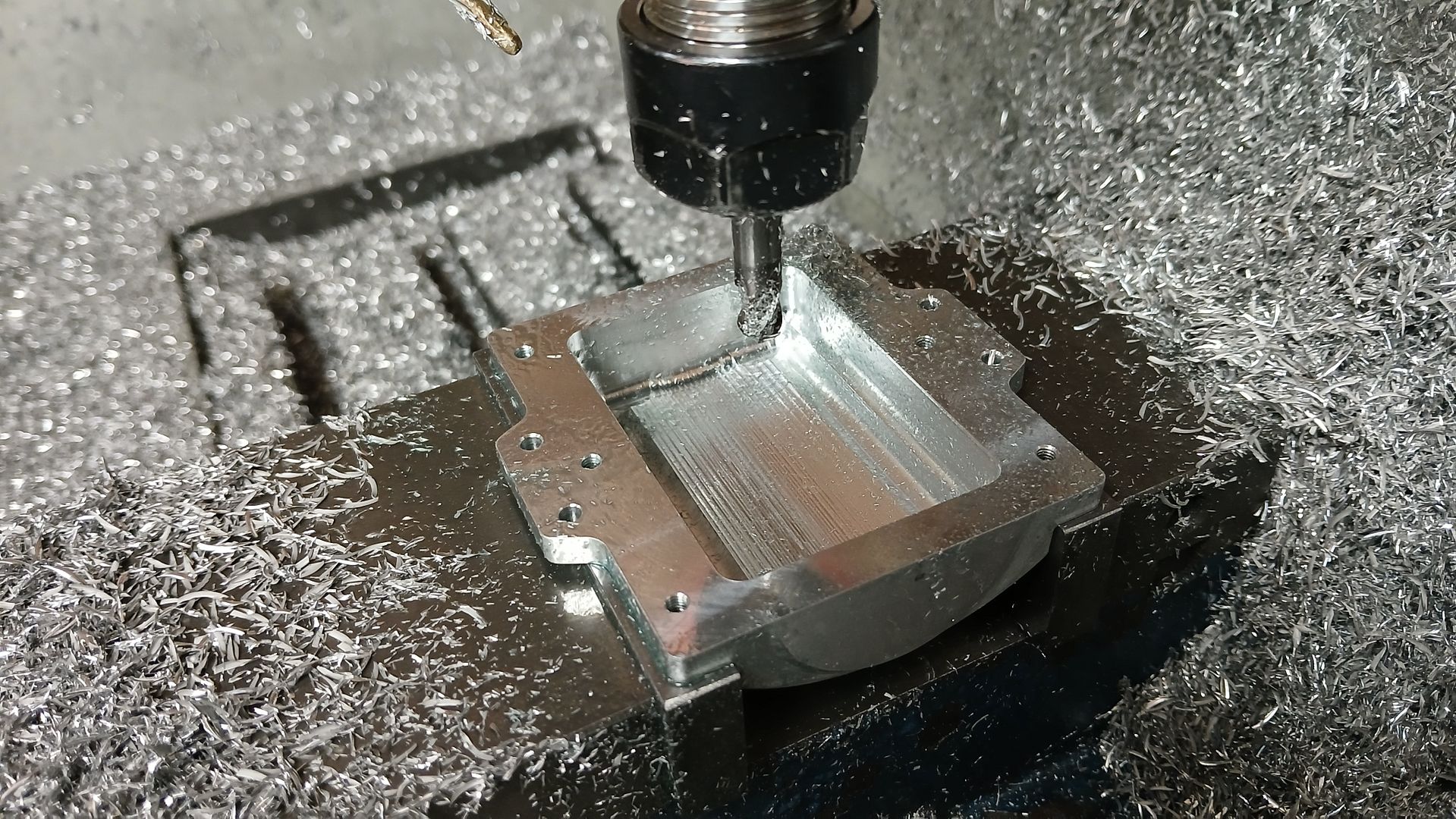

Repositioned in the vice the other way up an adaptive tool path was first used to remove the bulk of the waste material

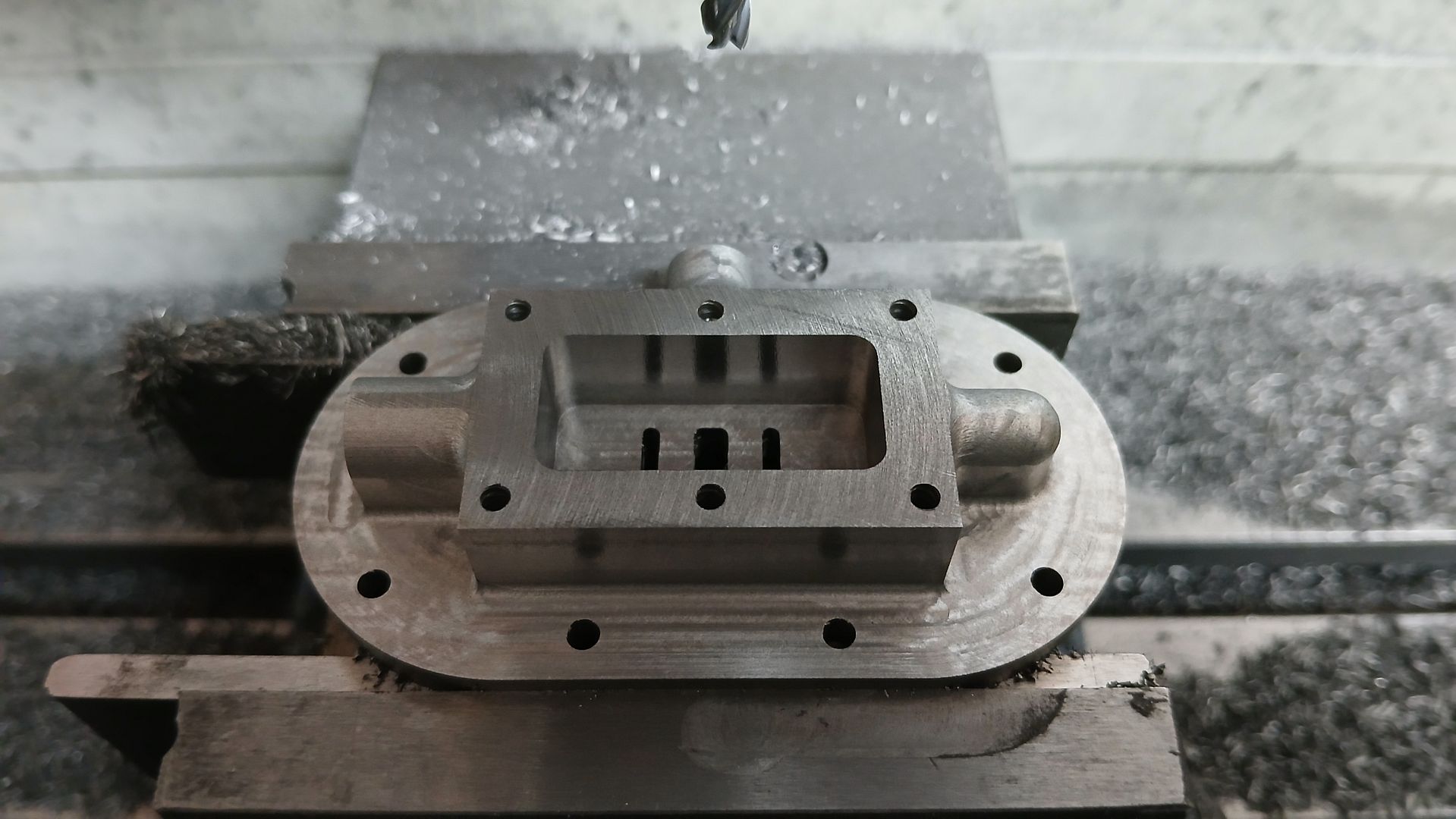

This was followed by scalop and horizontal finishing paths, a bit mor edrilling for the cover screws and repeating the ports to join up with the cut from the underside.

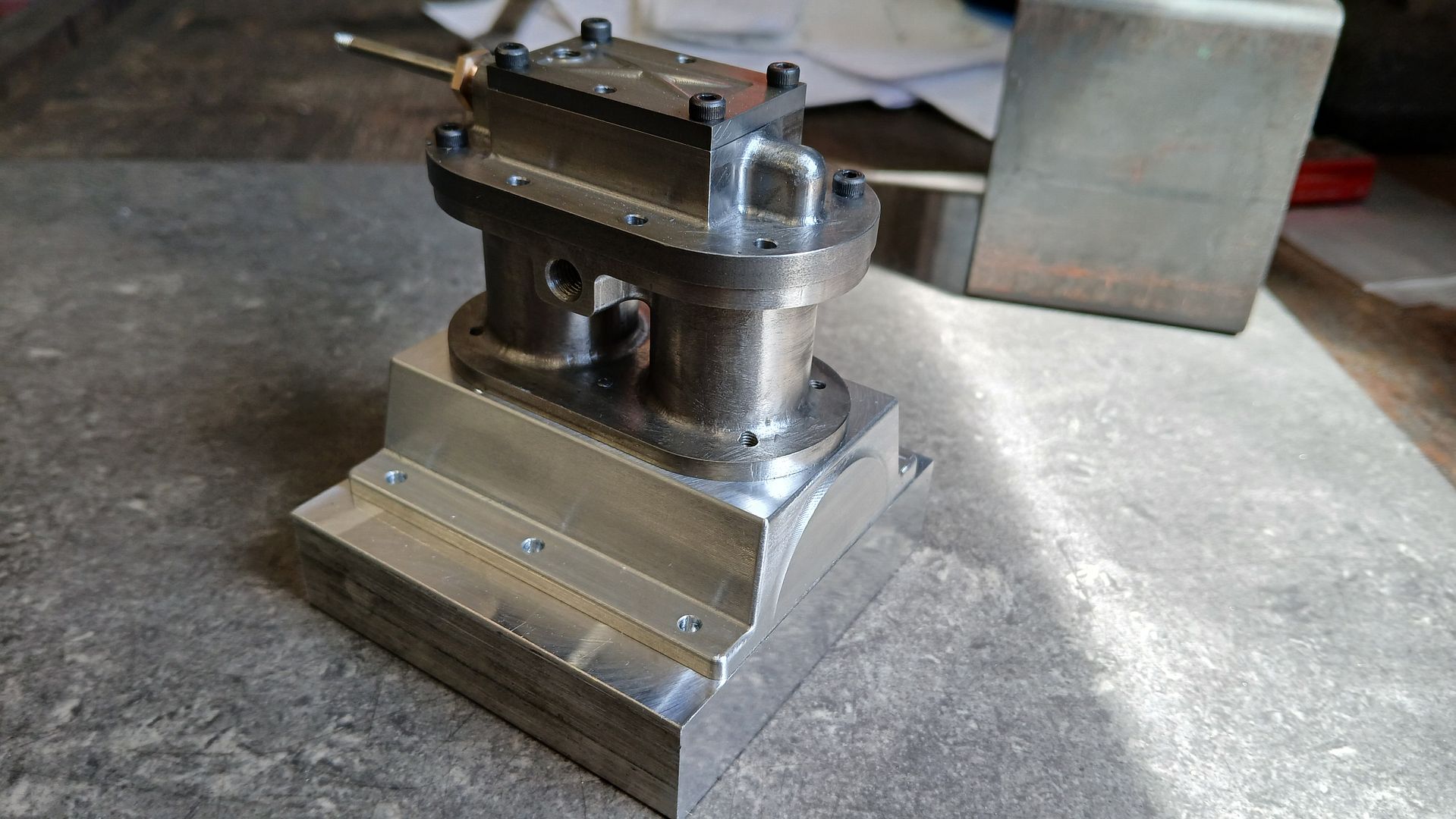

One “casting” in the hand to give an idea of size. Did i mention that when machining cast iron on the CNC your hands don’t get anywhere near as dirty as they do on the manual ones!

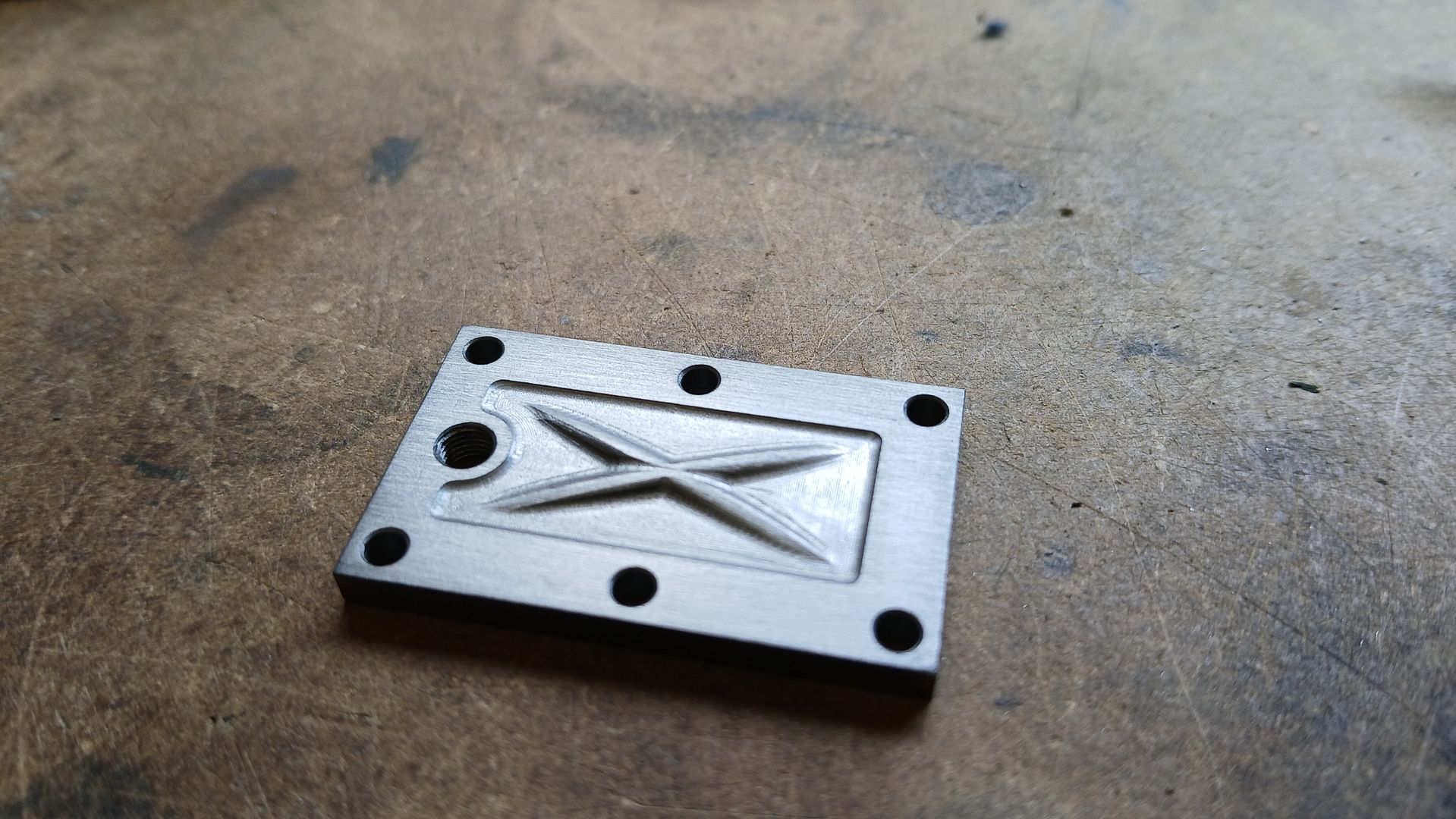

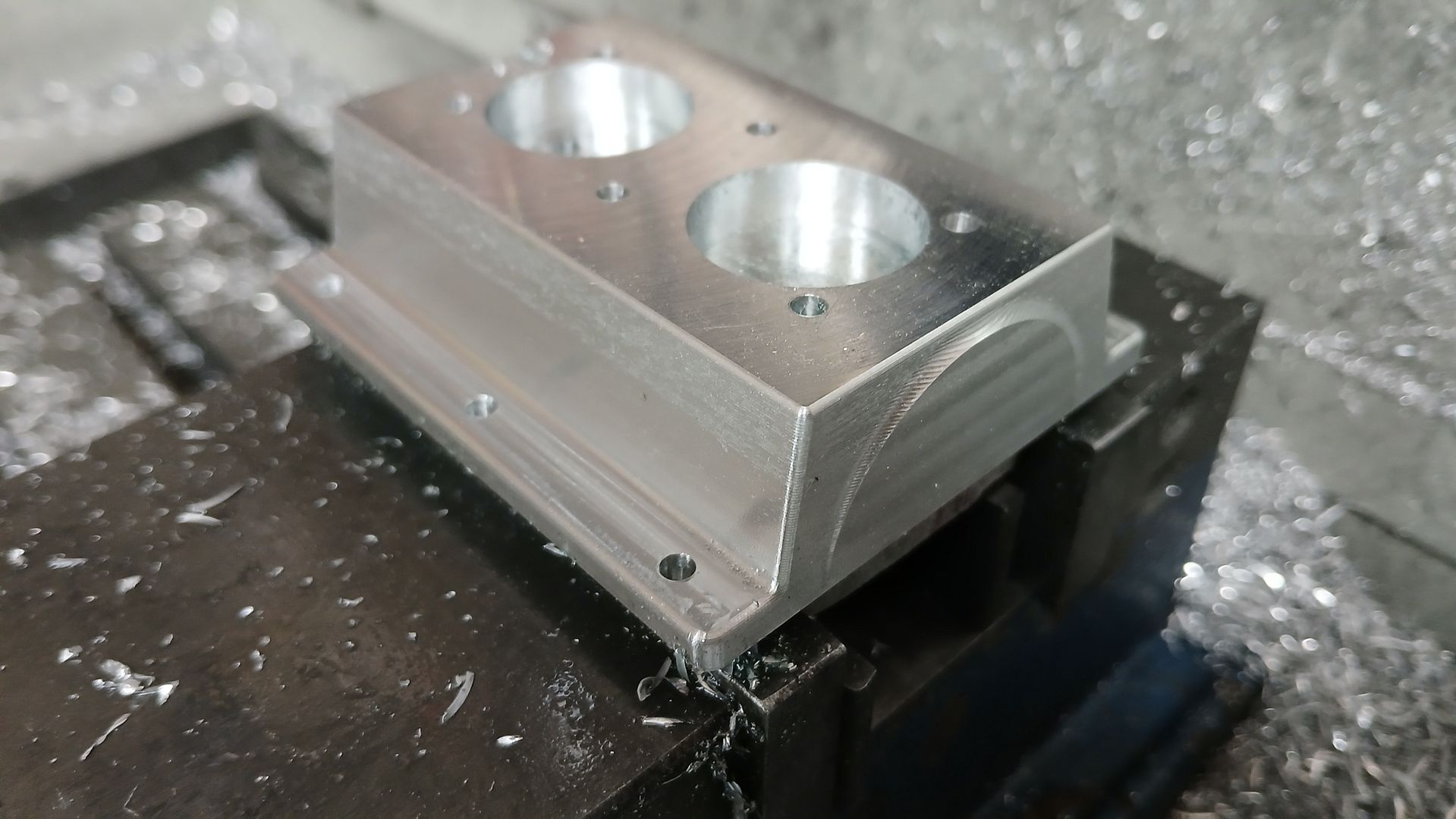

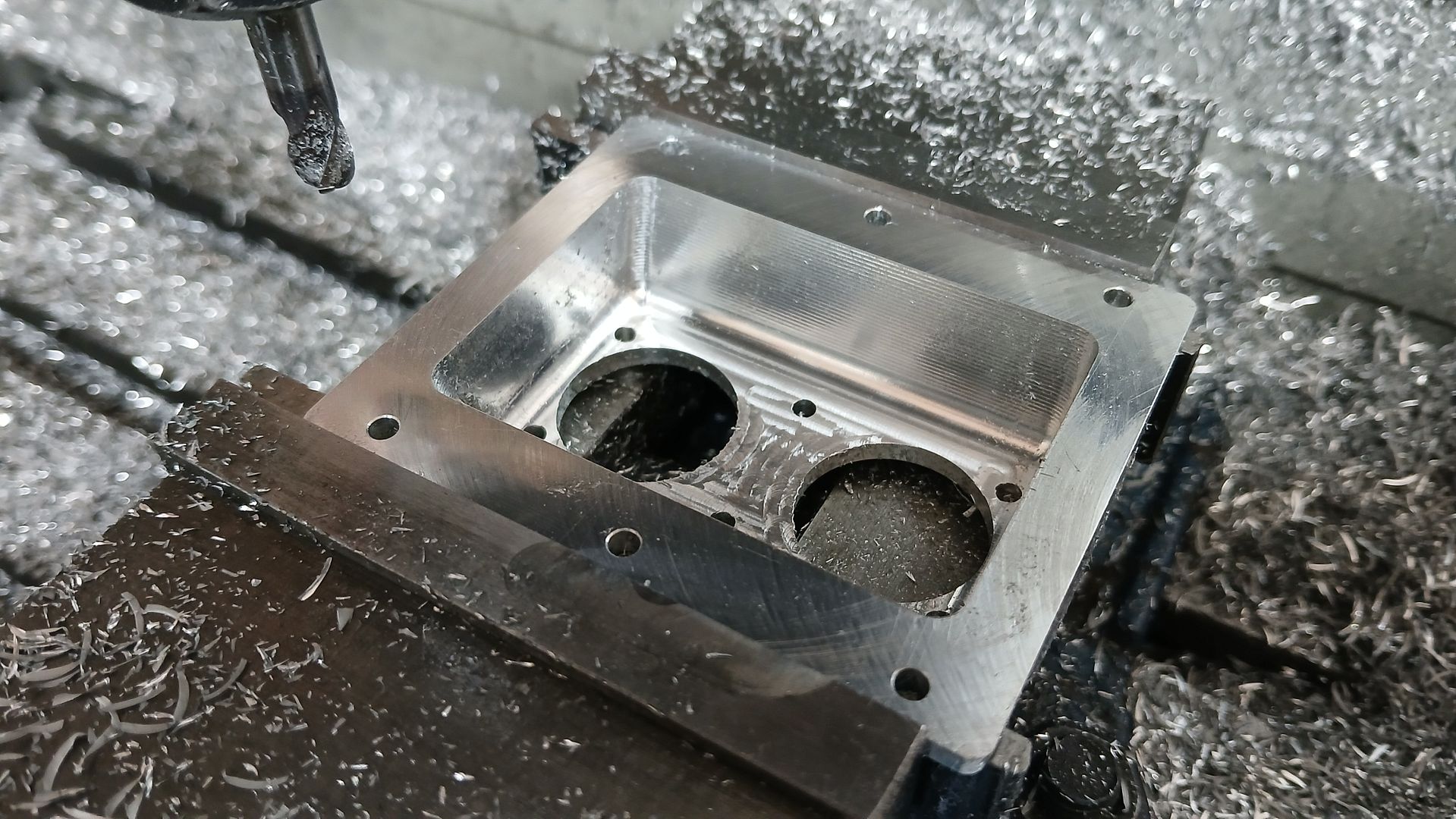

The cover was done in a similar way with an adaptive followed by finishing scalop and some clearance holes for screws, the larger hole is for a plug to allow access to oil the valve.

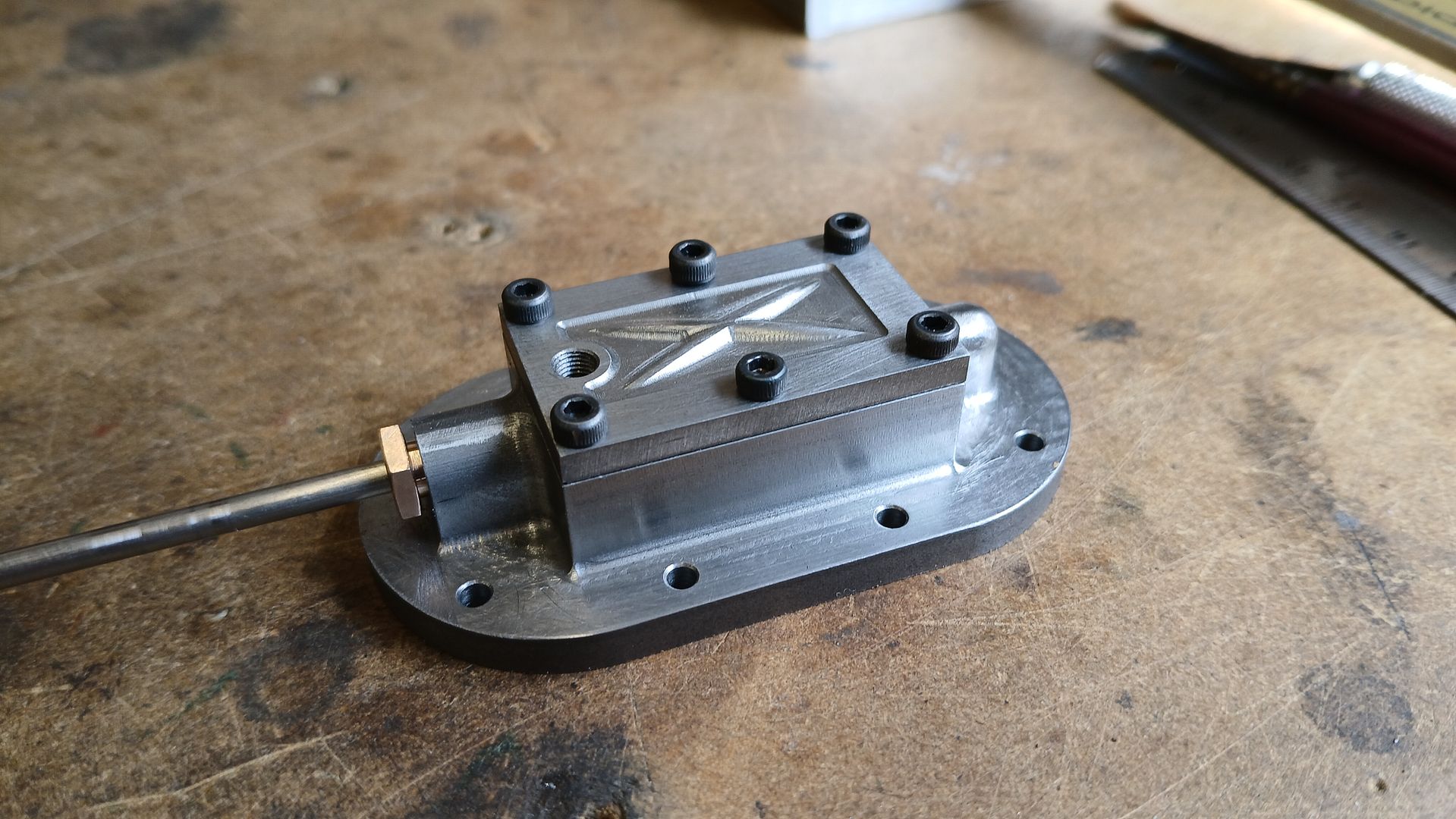

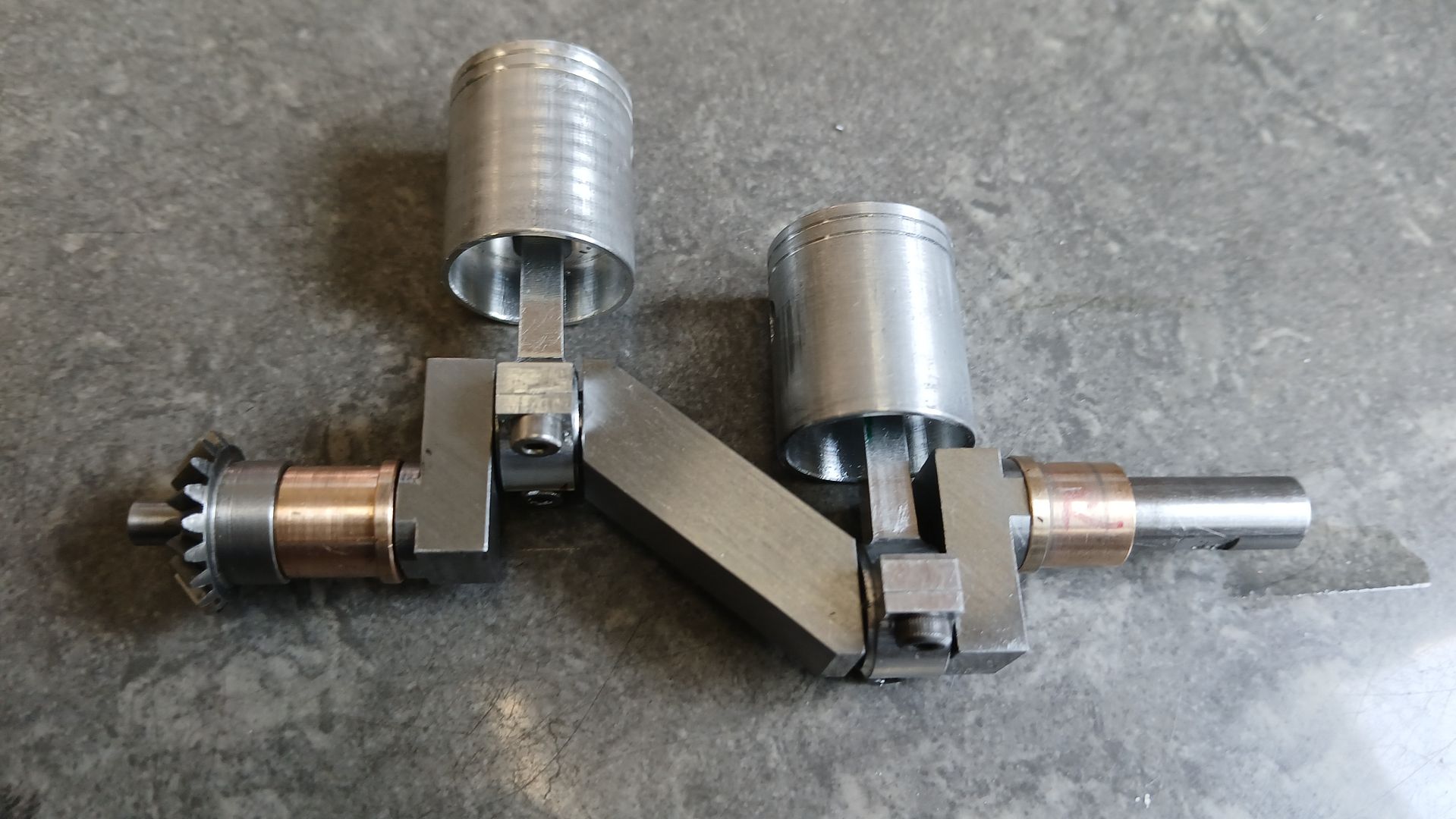

The cylinder head just needed drilling and tapping for the inlet, valve rod and gland which are tacked together here. I will be making suitable slotted head screws but the cap heads are easy to use during the build. These ones are M2.5 rather than the original 3/32″ Whitworth.

JasonB.

JasonB.