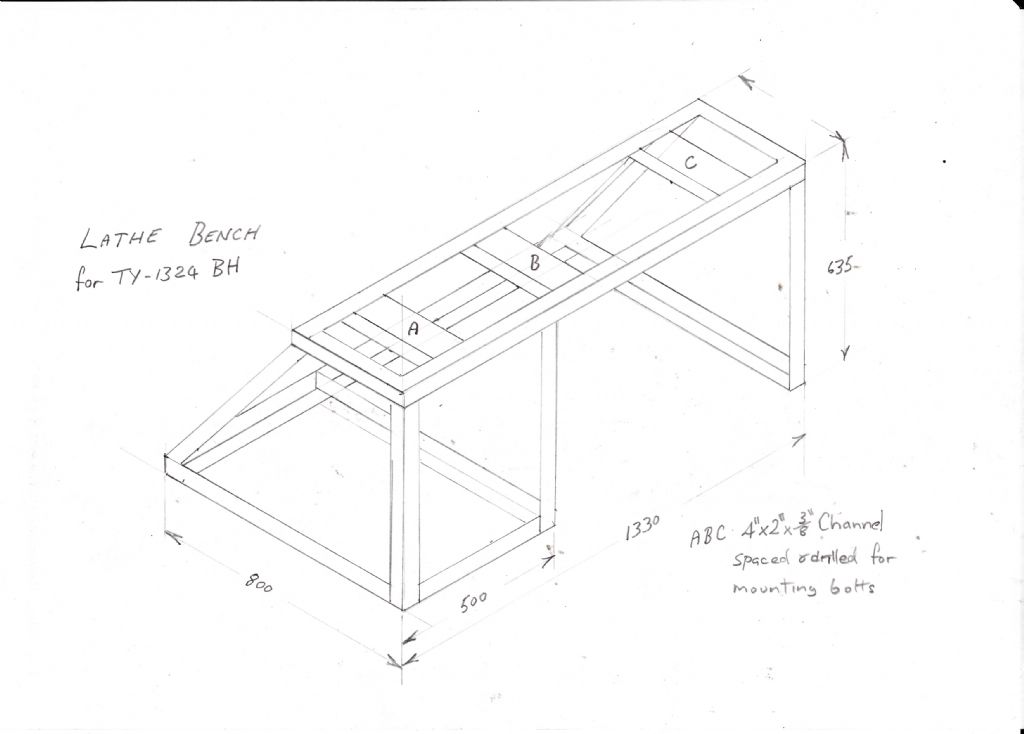

I want to buy/build a stand for this lathe, i guess it weighs about 200+ KGs and is like a Myford on steroids, so the drip tray needs to be about 60" long. having searche d the web, I can't see any lathe stands that would be suitable, so have been cogitating on building one myself.

The biggest hurdle I see is how to transfer the weight of the lathe from its 6" X 4" mounting feet outwards to the vertical stand members ( legs?) which will be about 28" front to back. How do Myfords do it?

I thought about making the drip tray out of 2mm steel with bent up edges, but with the front corners cut at 45 degrees with its own bent edge. This is to overcome a dead sharp right anngled corner that one day will cut me. it would be nice to put on a 1/4" round section lipping to finish the top edge off. Any suggestions? I am trying to figure out a way to put a small slope on the drip tray so liquids will flow to the front left hand siide where I could install a filtered outlet into a tank. The method I am thinking about is to put a 3mm shim under the tray at the headstock, then another ontop of the tray, while at the tailstock end, a 6mm under the tray, so the tray will fall 3mm from tailstock to headstock, with another 3mm to the front. Has any one attempted this – and did it work?

Any sources/ comments would be welcome.

Frank

frank brown.