Hi, respected experts.

And the rest of you!

I have a 100mm dia slitting saw in my CMD10 micro mill.

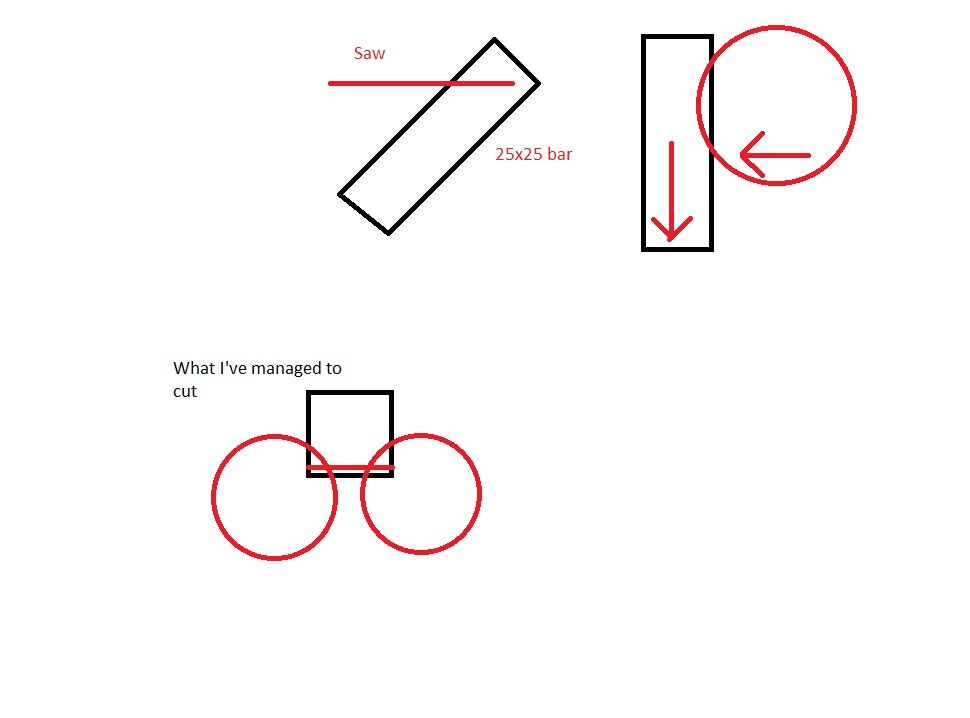

I'm trying to cut off a piece of 1"x1" mild steel at 45 degrees. I have the bar clamped on an angle plate at 45 degrees with the bar rising up from front to back.

The I'm running the slit saw from front to back (the table moves towards me). For the main part, this is fine until the saw gets to the end of the bar at which point it start to struggle, regardless of the feed speed, and jams. saw speed seems to make little difference, though it's a bit better at high speed due to more power and inertia.

I'm cutting off about 1mm.

I've tried slitting the back for a bit and that works OK until the cut gets too deep (there's not much scope for getting to the front and back with 150mm travel). when it jams.

I had very similar problems last time I tried to cut with this and gave up. However, In the past I've succeeded in cutting decent chunks with a slitting saw (the last time it worked I was cutting a one inch square 12 inch long cast Iron bar all the way along at an angle of 55 degrees).

I've put an indicator on the saw. There's a wobble of around 4 thou as I rotate it – which is consistent with a 1 thou spindle wobble at about 150mm down.

There's a few thou rise as the table moves left to right and there appears to be a ridge – that is as you move towards the centre of the saw the indicator rises by a thou or so over perhaps 10mm and then settles down. I suppose I should put the blade on my surface plate and check it.

None of these factors explains to me why it's jamming (and blowing fuses at an alarming rate).

Could this be happening because the blade is blunt? It's not done a lot of work, but perhaps my ham-fistedness has scored another own goal.

Am I expecting too much?

I wanted to use the saw to get a great surface finish (this is for a sliding clamp), and of course I don't fancy the hacksaw approach. I could revert to hacksaw, mill and lap, but I'd like to know what I'm getting wrong this time!

Iain

Michael Gilligan.

Michael Gilligan.