Sliders too tight

Sliders too tight

Home › Forums › Beginners questions › Sliders too tight

- This topic has 33 replies, 11 voices, and was last updated 6 February 2019 at 13:27 by

Simon Williams 3.

-

AuthorPosts

-

31 January 2019 at 23:39 #394055

Chris R 1

Participant@chrisr1I've been playing with a microscope flourecence cube holder. Different issue with it was described in another thread here

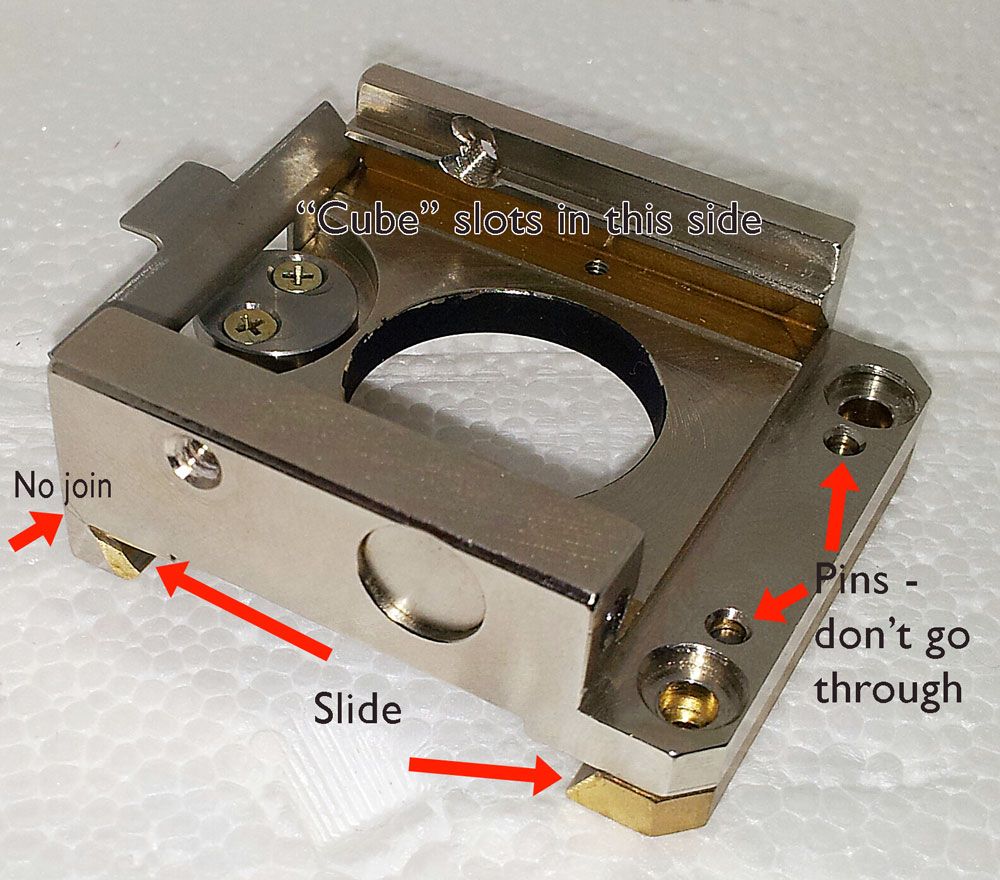

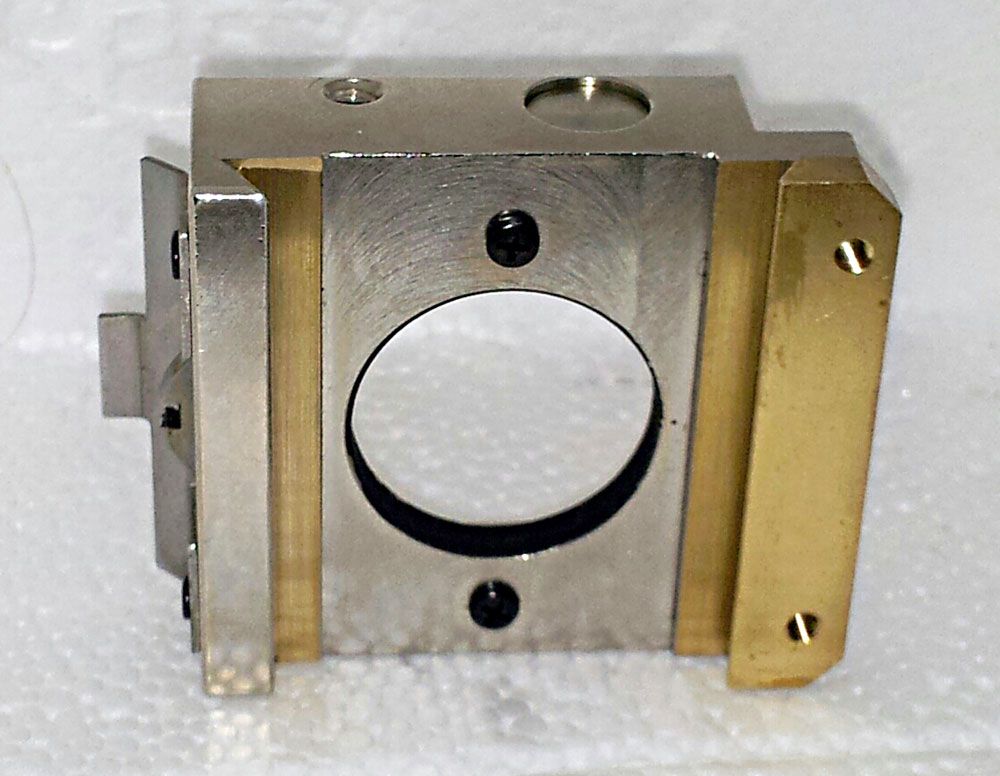

There are two "cube carriages" which slide along a dovetail.

Dovetail is about 3cm wide, 4mm tall. and 150 long.

the contacting faces are about 4mm for the angled face then 5mm of flat, each side.

Male part is machined out of Al alloy block, female (carriage) is steel one side, and bronze(?) the other.

I have two of these. One was so stiff that I dismantled, cleaned out the remains of the old grease…. but it's not better. fine application of WD40, still no better. If anything it's worse. It takes a strong thumb pressure to get it to move.

I know aluminium can "pick up" against Al, but does it do that with other metals too?

I've got the carriages off, and though one side should unscrew, the screws are small and "glued" in with something. I don't fancy my chances of releasing them. Is there something I can leave them soaking in to soften thread locking stuff?

What about the slides – is there a metal polish I can put in to work it with to remove some of the Al?

A doodle:

I could try a few wipes with 1200 grit WC paper?

Edited By Chris R 1 on 01/02/2019 00:09:21

31 January 2019 at 23:39 #9509Chris R 1

Participant@chrisr11 February 2019 at 00:25 #394063Jeff Dayman

Participant@jeffdayman43397Are you sure there is no gib strip on the steel side? If there is no gib strip, and no way to adjust the tension of the bronze piece to the alum dovetail, I don't think your slide is fit for use, as it will be extremely difficult to adjust it to move smoothly along its' travel. It's a dumb design in my opinion.

You might be able to salvage it by adding a steel strip / plate at the right of the assy, with screws into the right end face of the steel, and into the side face of the bronze. That way you could add shims between new strip and bronze to adjust the bronze piece's fit to the dovetail, or add two adjuster screws between the fastener screws of the new strip.

Aluminum if tempered and anodized may JUST be OK for a dovetail if not used too much. It probably will not pick up, but it sure could wear. Is this item a cheapy from the far east, by any chance? It has the hallmarks of some products from there where materials not optimal for use together and not really suitable in the given mechanism are substituted to make a cheap saleable thing.

Just food for thought.

1 February 2019 at 00:47 #394066Chris Trice

Participant@christrice43267The Emco Compact 5 vertical slide is a cast iron top running on a plain aluminium dovetailed base with a Delrin gib strip.

Edited By Chris Trice on 01/02/2019 00:47:49

1 February 2019 at 02:11 #394070Chris R 1

Participant@chrisr1I've looked it up, and am still not sure what a gib strip is!. Often rails have a trianglular sectio n adjustable strip, if that's the sort of thing you measn.

The "ally" on the dovetail itself is too shiny to be anodized. It's fairly hard stuff. Maybe one of the hypereutectic silicon alloys.

It's far eastern, when Nikon made stuff in Japan. When this was made, back in the 80's probably, it would have cost around £5k for a set of objectives, a few £k for the rest of the microscope and and a couple of thousand for this part. The "cubes" used with it are now hundred new, each.

Leitz would have been a lot more, and better made, and Olympus a bit less.1 February 2019 at 04:24 #394071Chris R 1

Participant@chrisr1"hundreds" new, each..

I don't want to alter this thing, I don't have the resources or skils to do that. I agree it could have been made better. All I can think of is to try to remove a little material, somehow, then grease it. Any suggestions how I might do that?

1 February 2019 at 06:38 #394072Joseph Noci 1

Participant@josephnoci1Chris (R1) – There are many microscope focus stages and optical bench slides that are aluminium on aluminium and aluminium on brass – made by some of the top optical system manufacturers. Since there is very little weight bearing required and the movements are small and slow, lathe type slides and gibs are definitely NOT required!

To understand a little better – you say a very firm push is needed to move the slide – can you, to the best of your 'pushability', determine if the resistance to movement is is similar across the slides full length? This will at least tell that the dovetails are straight and aligned.

Then try this process over the full length of one side of the base dovetail.

Adapt the sanding block dimensions described to suit the length of the dovetail as I have no idea of the size of the device:

Cut a piece of Aluminium or brass sheet, say 2mm thick, around 50mm long and slightly wider than the acute angled section of the base dovetail. Make sure it is as flat as possible – work it flat against a sheet or 200 waterpaper on a sheet of glass maybe..Bevel one long edge so that the strip can fit snugly into the dovetail corner. LIGHTLY apply a contact adhesive to the strip face and glue on a strip of 1200/1600 water paper. Move the sliding stage to one end on the slide. Apply some turpentine or paraffin to the abrasive surface. Press the abrasive gently up against the dovetail and gently slide it back and forth 2 or 3 times. Keep wet with the lubricant.

Clean and move the slide to the now sanded end, noting the effort required to move the slide, Repeat the process at the other end, and keep doing this till the slide just begins to loosen up.

If the stage is tight at ant point, that location needs a few strokes more, etc.

As it loosens a little, clean and apply a thin oil to prevent galling, and move the slide end to end half a dozen times. Take a close look at the slides and see where the rubbing occurs and gently work those areas over – sort of like scraping slide surfaces..Abrade the rub mark away and keep repeating – it goes surprisingly quickly and leaves a good result – from experience! Go very gently on the abrading process, less and less pressure and fewer strokes as the slide loosens up.

When happy, clean, and apply a thin smear of a light grease.

There is another way, depending on the actual construction of the sliding part – you could apply a slight pressure to the centre line of the moving stage, ie, centred between the two dovetail edges, test the movement, and if still tight , apply a greater pressure, etc. The applied pressure needs to be WELL controlled – the idea being to slightly 'bend' the stage so that the dovetails move apart. The amount to bend would be in the order of a few thou, so very difficult to control, and if overdone, the stage is useless…

Joe

Edited By Joseph Noci 1 on 01/02/2019 06:39:22

1 February 2019 at 09:42 #394100Kiwi Bloke

Participant@kiwibloke62605I would regard the use of abrasives as a last-ditch manoeuvre. There's always the risk of abrasive grains embedding themselves in the soft material and continuing to abrade for evermore. Also, you can't put the substrate back, after you've taken too much off. We've all done it…

If the thing is as sketched, I would expect that it was assembled by holding all bits tightly together, then tightening the screws. The through holes would have allowed a little movement, so the slide could be assembled rattle-free. With any luck, the screws are fixed with some form of Loctite-like adhesive. It would be worth cooking the assembly in the oven at, say 180C, to soften the adhesive, and then have another go at loosening the screws.

WD40 is a poor lubricant in some (many?) circumstances. When you've fixed the slide (by whatever means), there are specialised lubricants that increase their viscosity under shear – the opposite of thixotropic (can't remember the correct term. Was Kilopoise one trade name?). These make slow-speed mechanisms move beautifully, and are used in optical devices and things like rotary controls on hi-fi gear. RS Components used to sell them. I can't find any on the shelves here in NZ, but, for similar purposes (micrometer threads, etc.), use an 'assembly paste' (Molybond GA 50), which is a stiff grease containing 50% Molybdenum Disulphide. It's a pretty good substitute, and has the advantage that it's intended to prevent 'pick-up' and galling.

1 February 2019 at 10:09 #394113Simon Williams 3

Participant@simonwilliams3+1 from me for NOT cutting metal – at least not yet. I can't believe those jolly clever chaps at Nikon made something which isn't fit for purpose, they are much more diligent than that. This is the sort of thing they are good at.

Aluminium as a slider in this application is perfectly fine, and if it galled up you would be in deep trouble, it would be jammed absolutely solid. I feel this is more about age, and the sticky-ness of rancid and probably dirty grease.

WD40 is good at freeing things, but after a short time – a day or so – the residue it leaves starts to dry and go sticky again, so it may be that the cure is worse than the illness. I would be using IPA or even brake cleaner, carburettor cleaner is good too as it dries faster but it can pickle the paint. With the old grease out of the way the slide should move easily – too easily, so add some oil or grease to slow things down again. If the slider is still too stiff when you have cleaned it then there are still grease remnants in there, or a burr from someone else's heavy handed-ness trying to rectify the same problem.

I would bet almost anything that the slide doesn't need to be adjustable as it is made accurately enough to control the clearances. This isn't a machine tool its a precision instrument.

If I've understood correctly, you have managed to get the assembly with the stuck screws off the microscope. If they were assembled with Loctite your best bet is some heat – low oven, say 120 C or so. Loctite is pretty much immune to solvents – so soaking them is not going to help. If they are stuck because of the passage of anno domini, try some white spirit or paraffin.

HTH, go gently at it, and don't start introducing abrasives unless you can be sure to clean the residue out again afterwards.

Simon

1 February 2019 at 10:09 #394114Brian G

Participant@briangI would tend to agree about the brass dovetail. Why go to the expense of making it a separate part unless it is adjustable?

Could I suggest being careful with the screws if they are cross-heads? A lot of older Japanese equipment has JIS and not Phillips screw heads (as if Phillips vs. Pozidriv wasn't bad enough). Hard to identify by sight, but they may have a little dot in one quadrant. Larger sizes are available from Machine Mart, whilst there are plenty of JIS instrument screwdrivers on Amazon.

Brian

1 February 2019 at 11:16 #394133Clive Foster

Participant@clivefoster55965Having worked on micrometer adjusted optical slides of similar, but not identical construction with similar issues I agree that its a completely take it apart, clean and re-assemble issue.

The trick is to maintain the correct spacing between the brass dovetail and the fixed dovetail as you tighten up the screws. Darned if I can recall exactly how I did it.

I imagine it involved tightening up the screws a tiny bit at a time followed by stroking backwards and forwards a few times to settle things absolutely parallel before tightening a bit more if no tight spots encountered. If a tight spot is found then the screws need to be released a fraction to let the slide take up a new position with enough clearance to move freely before stroking an few times and continuing with the tightening process.

Assuming the sketch isn't over-simplified I'd not consider it a clever design. In the optical lab equipment world similar systems used caged ball bearing slides giving a whisker more freedom of action and error tolerance. Still a total pain to get just so tho'. The fundamental issue with that design is that you only have control of dovetail way spacing but the top also sits on the return edge of the dovetail L shape. For the thing to work properly the top needs to be absolutely parallel to male dovetail so the brass, free, dovetail needs its top machined to exactly the right thickness. Difficult. I'd expect jack screws as well as fixing screws to get the top dead level. Which adds another level of complexity to free hand adjustment.

If it does have jack screws then original assembly might well have been in a jig holding the two female dovetails together on the male dovetail at the right clearance so the top could simply be screwed on against the jack screws. If done this way assembly would have been a very fast process with almost no fiddling around. If you have the facilities seriously consider making an external jig to set the dovetail clearance independent of the screw tightening process.

Clive.

Edited By Clive Foster on 01/02/2019 11:16:56

Edited By Clive Foster on 01/02/2019 11:18:04

1 February 2019 at 11:35 #394136Chris R 1

Participant@chrisr1Thanks all, I'll digest what you have all said.

It is possible that I've mis/not represented something. Bush would have said misunderestimated. Donald (the other one) would have wondered about unknown unknowns.In the past I've found methylene chloride softens/dissolves many things. Think paint stripper. It softens Aradite and other epoxies, for example. I should try things on the "paint" on the screw(s) I have managed to remove.

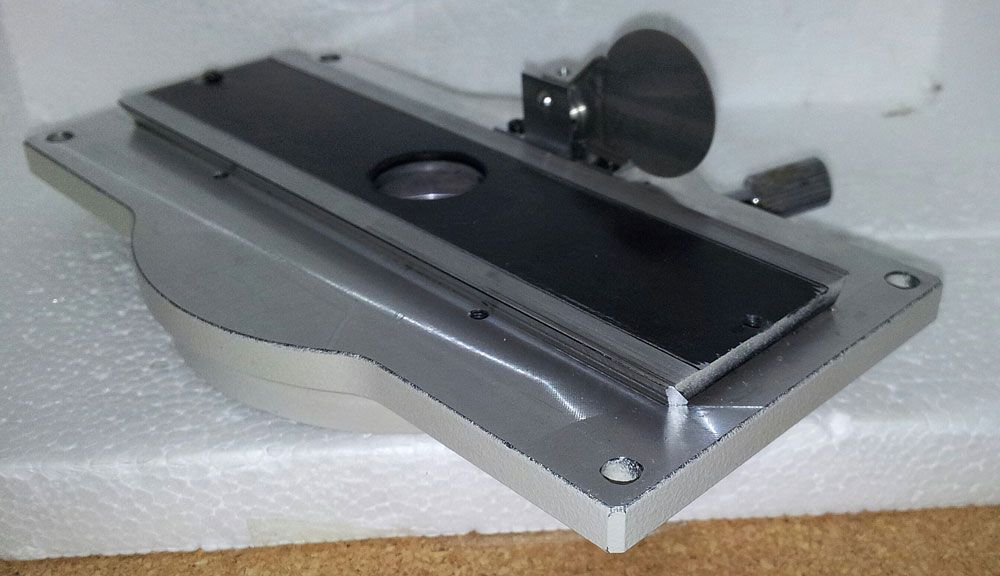

As in the top if the first post, the slide is around 150mm long.

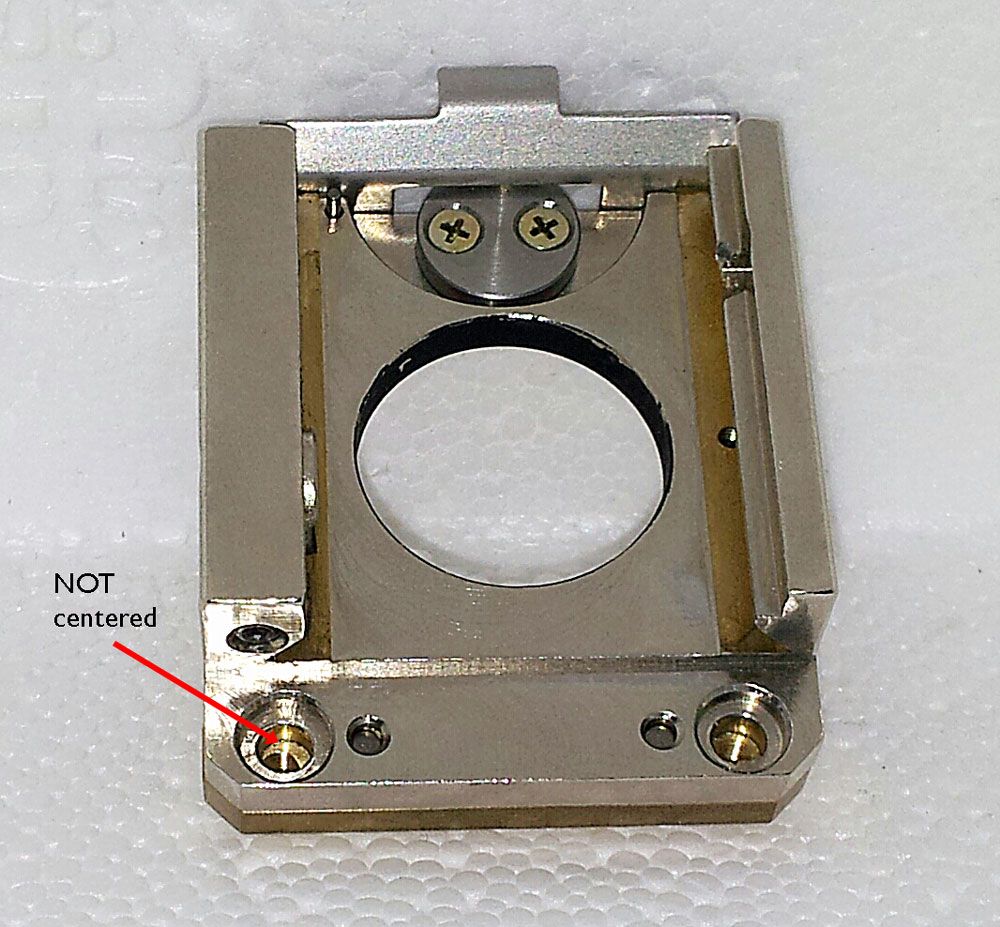

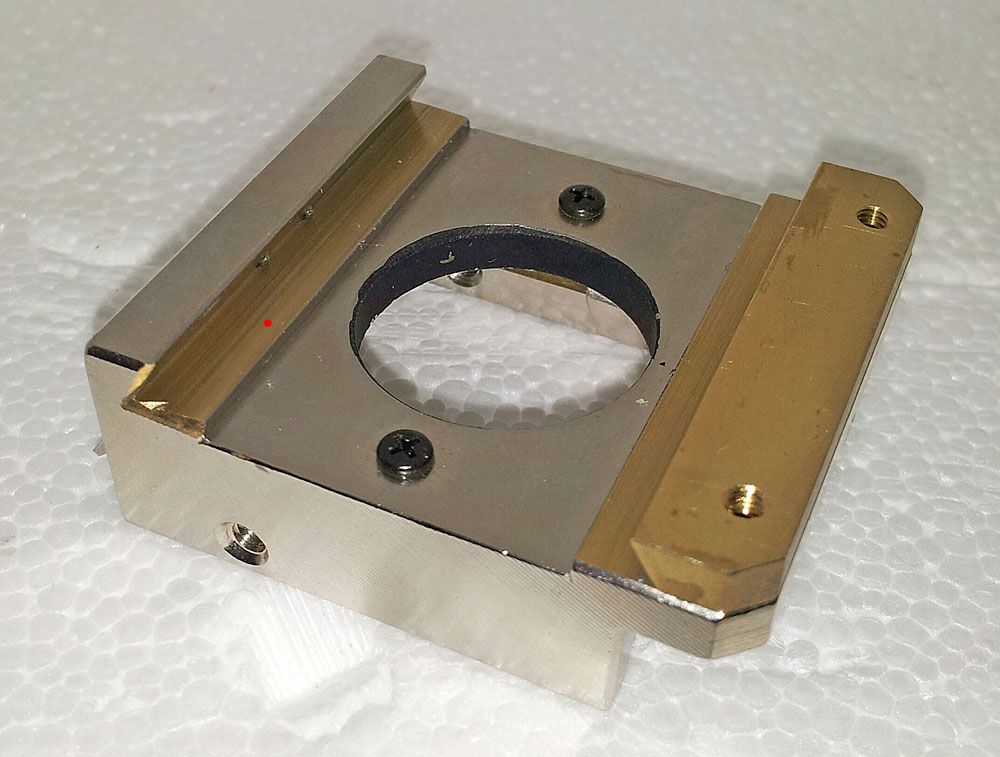

The male part is machined from thick solid.Overall these may help, or not. Item pics to come. I'm a teacher – class prep to do!

I have removed an end-stop screw to slide the carriers off one end. One part of the run is less stiff, for either carrier. One carrier is slightly tighter than the other.

It needs some pictures, but they do tend to encourage opinions about redesigning things!.

I have a set of JIS screwdrivers 2,1,0,00, though they elude my search at the moment. I will look for micro ones to buy. These screws do have very narrow "arms on the crosses".

The bronxe(?) parts appear to be pinned, as well as screwed, so I'm guessing they wouldn't "move across a bit".

"lubricants that increase their viscosity under shear" – that sounds right !

I'll look at RS etc.

I'll look at RS etc.Edited By Chris R 1 on 01/02/2019 11:57:34

1 February 2019 at 12:05 #394142Joseph Noci 1

Participant@josephnoci1Perhaps actually reading Chris R1's post carefully may help….

Chris R1 said – I have two of these. One was so stiff that I dismantled, cleaned out the remains of the old grease…. but it's not better. fine application of WD40, still no better. If anything it's worse.

Assuming he DID dismantle it and clean it I assume it is not a problem of 'I feel this is more about age, and the stickyness of rancid and probably dirty grease.'

Chris said clearly – The "ally" on the dovetail itself is too shiny to be anodized. In which case the dovetails are clean and not sticky with grease..

He also says "The bronxe(?) parts appear to be pinned, as well as screwed, so I'm guessing they wouldn't "move across a bit".

In which case, use my method…

I would NOT recommend heating the carriage, at least not to the aforementioned 180degC – any warpage or twist in the carriage and its destroyed. You have little control over that. The tolerances are very fine…And since the parts are pinned, there is little to be gained – remove screws, remove pins, try to reset the dovetail and screw down and drill new pin holes, which will hardly ever be in the correct place…

With regard to 'abrasives'… I did not suggest a bastard file or beach sand, only 1600 grit water paper with turps as lubricant, and 2 or 3 gentle passes…And you overate the issue of 'embedded abrasives' in this method – the pass is gentle and when well washed with turps or the like, a pass of Brasso on a wadd will clear all abrasives of note. In any case, if there are one or two particles 'embedded', they will only 'cut' as deep as they protrude and no more, ever again..they do not continue to abrade as they do not move in this application. I think we harp on this issue because it is compared to far more stringent lapping , perhaps in the lathe, of pistons and cylinders, where the process is more complex, with the lapping paste being a mix of loose particles, while the waterpaper is not. A few particles may come loose, but the action of the process is far more gentle than lapping in a lathe where we are forcing the particles to fit between the cylinder and the lap…

"+1 from me for NOT cutting metal" – Similarly , we are not 'cutting metal' but abrading away 1 or 2 thou in an easily controlled manner.

Chris, if you wipe the slides clean and apply a little thin oil, then work the slides back and forth say 10 times, then take a look at the rub marks, where do they present? are they evenly distributed? On the angled dovetail section as well as the flat section? If so, there is potentially no twist or warp and my proposal will fix it.

Chris R1, I would STILL rather go the abrasive route. I would not heat that slide to soften the screw glue..

Joe

Edited By Joseph Noci 1 on 01/02/2019 12:12:12

1 February 2019 at 17:43 #394209Howard Lewis

Participant@howardlewis46836Coming in late, with comments / suggestions.

If it is Nikon, the quality should be pretty good.

Avoid using any abrasives, grinding paste / emery etc with soft metals. Some abrasive particles will embed in the soft metal and it will then act as a lap every time that it is moved.

If you have, wash and clean VERY thoroughly, in the hope of removing the particles.

For a lubricant, do not use Coppaslip. Copper and Aluminium are a bad combination if there is any humidity (Electrolytic corrosion).

The WD40 will have removed the grease, which had probably dried out. and as the lighter fractions evaporated, there was no lubricant left, hence the stiffening. Ordinary mineral oil should be O K. Avoid active oils, such as Hypoids, or any containing sulphur, since they are designed to react with metals, although having Extreme Pressure additives.

Cleaning and relubricating should suffice, unless there is wear, but then the movement would be unlikely to be stiff, but loose and sloppy. If any galling is present, the movement will be rough and irregular. Any galling needs to be removed by very careful and judicious scraping. It is amazing how a little oil reduces friction.

If you want to have the "gibs" adjustable, is there room to replace the setscrews with studs and nuts and lock nuts? Fix the stud in the lower part, adjust with the nut, and lock with the second nut.

H T H

Howard

1 February 2019 at 19:49 #394236Joseph Noci 1

Participant@josephnoci1Howard,

Some abrasive particles will embed in the soft metal and it will then act as a lap every time that it is moved.

This is not correct – Please think carefully on this. When lapping on a lapping plate, or as I said before, lapping a cylinder/piston, the motions and action is VERY different. On a lapping plate, the lapped item is moved in X and Y, and often rotated at the same time. Similarly, an internal lap in a cylinder is moved in and out of the cylinder, while it rotates. Any embedded particles are thereby FORCED to contact the lapped surface repeated in different places.In addition ALL the lapping abrasive is loose and distributed.

This is not so with the particles entrapped on the surface of the water paper. Some particles will come loose, but as we are not FORCING the particles to fit between lapping surfaces under fair pressure, the chance of embedding is very low. However, should embedding of a few particles occur, there is not the same arbitrary lapping motion when the slide moves. Solitary particles will, if you wish, wear a single groove the depth equal to the size of the particle and NO MORE. since the motion is linear, no more new grooves or lapping will take place. It is not as though the surface of the slide is saturated with embedded particles!

Please get this right!

Joe

1 February 2019 at 21:50 #394261 Fowlers FuryParticipant@fowlersfury

Fowlers FuryParticipant@fowlersfuryYour other post might suggest the 'scope has been used in a path lab. Do you know its working history?

My experience of some path lab technicians was that they could get tissue fixative all over the stage of microscopes. Most fixatives are not oil soluble, so WD40 etc won't remove any dried residue. Herewith extract from current Leica fixative data sheet "Cytology Fixative combines a convenient fine-mist spray dispenser with a polyethylene glycol formulation to enable the rapid, high quality fixation of cytology cell spreads.Cytology Fixative covers cells with a tough, soluble film that protects cell morphology for microscopic examination. It is water and alcohol soluble".Of course if you know your 'scope has never been used in such conditions then the foregoing is totally irrelevant (like most of my postings !).

1 February 2019 at 22:19 #394265Howard Lewis

Participant@howardlewis46836Joseph,

Abrasive particles will wear if they are present. Either that or I've been misled for the last 60 years in manufacturing industry. How rapidly will depend on the pressure between the surfaces, even if lubrication is present.

Believe me, I have seen it happen.

We insisted on there being less than 5 mg (total) of debris in the oilways of an engine, for that reason.And we are taliking upto 9 litres swept volume.

Many times on this forum, there are warnings about the abrasive effect of cast iron dust and oil, as a lapping paste, on the bedways of machines; and cast iron contains graphite (a lubricant) as well as ferrites.

In this instance, there will be forces, since the two male and female dovetails are being held in contact.

Sadly, I remain unconvinced by your argument

Howard

2 February 2019 at 00:14 #394280 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Just for background info.

The pictures in this completed ebay listing might help people visualise what Chris is working with.

… then click on [ View original item ]

MichaelG.

.

Edit: I note your comment, Chris, and I do intend that ^^^ to be my sole contribution to this thread

"It needs some pictures, but they do tend to encourage opinions about redesigning things!"

Edited By Michael Gilligan on 02/02/2019 00:25:30

2 February 2019 at 02:48 #394285Chris R 1

Participant@chrisr1Ugh lost a load of text when I went to upload pics – too tired to put it all in again, it's 02:43.

I was wrong, It's not steel, it's all copper alloy. some plated -as someone suggested.

The screws are out care of graffiti remover which dissolves everything. Even formica worktops. But the bits are still together. Pins of some sort..

Surface with red dot is smoother than it looks.

Hope it's clear, sorry they're grotty pics. Could do better. I have some fine SiC paper – but I'm bothered that the slide is just about jamming for part of its length and free elsewhere. I used lighter fuel and WD 40 – pretty sure all the old grease is off it.

zzzzzzzzzzzzzzz

Edited By Chris R 1 on 02/02/2019 02:52:48

2 February 2019 at 03:01 #394286Chris Trice

Participant@christrice43267When you say it's jamming, does it tighten up or does it come to a hard stop as if something is impacting something else? Plenty of clearance above screw heads?

2 February 2019 at 07:00 #394288Joseph Noci 1

Participant@josephnoci1Posted by Howard Lewis on 01/02/2019 22:19:28:

We insisted on there being less than 5 mg (total) of debris in the oilways of an engine, for that reason.And we are taliking upto 9 litres swept volume.

Many times on this forum, there are warnings about the abrasive effect of cast iron dust and oil, as a lapping paste, on the bedways of machines; and cast iron contains graphite (a lubricant) as well as ferrites.

Sadly, I remain unconvinced by your argument

Howard

Above post edited leaving salient points..

I repeat, again, it is a matter of quantity. You indicate this yourself in the 5mg/9litres….a FEW solitary particles loosened from, again, the GENTLE application of the waterpaper is not comparable to machine bedways covered in cast iron dust…The latter circumstance will in any case always leave a multitude of particles behind as it will be almost impossible to remove all, unless the machine is dipped and swirled in solvent..And yet these machines with some embedded cast iron abrasive still last 20 years plus under much more heavy and active duty than an optical slide.

The gentle sanding motion is not the same a trapping particles between machine bedways and the heavy carriage or between a cylinder and close fitting internal lap. I have mentioned this a number of times..the applied pressure during the sanding process is so low that NO particle will be embedded – caught, maybe, but easily swept away with solvent and a firm rub down with brasso and a cloth.

Emphasising a point by exaggeration of heavy industry application does not help the reader…

Perhaps you could explain ( in a PM maybe – as this discussion is not really helping Chris R1), how an embedded particle keeps abrading the two surfaces? If the motion of the surfaces are linear, in ONE axis only, and since the particle is no different from a cutting tool edge, it can only cut what it is in contact with. Once that is cut, the material must either move to provide new, uncut material to the cutting edge, or the particle ( the cutter) must move to contact new material. It's the same as cutting a groove in a bar in the lathe, using, say, a parting tool. Once cut, the cutter can cut no more unless it or the material is moved to contact the cutting edge. And, again, to avoid exaggeration, we are talking off a 'cutting edge' ( the particle) of around 3microns ( 0.003mm) in mesh size. If that particle is embedded by half its depth, it means it will cut a SINGLE 'groove' in the opposing dovetail surface of around 0.0015mm deep.

Hardly worth loosing much sleep over..

Joe

2 February 2019 at 10:09 #394302Chris R 1

Participant@chrisr1Chris T – "binds". Some grease has arrived so I'l try that. I'll get the luggage scales out. Maybe even

use a microscope.

use a microscope.On the "particle of grit" debate, IME as an undergrad metallurgist, abrading metals on a series of wet papers is the way you get to a mirror finish (which you then etch with acid to show the structure). But if you didn't throroughly was all the old grit from previous papers away between grades, then you had an ugly score which meant you had to go back and do it again. Grit would rollaround, I don't remember any embedding. Some bearings (I remember "white metal" crankshaft shells as a case in point) were designed to be soft so they allowed embedding of hard particles so they wouldn't cause trouble.

I wouldn't care to predict what could happen in a specific situation, ever, though.2 February 2019 at 11:50 #394329Clive Foster

Participant@clivefoster55965Ah-Ha. The pictures of the complete assembly reveal all.

That unit would certainly have been assembled in a jig to keep both dovetail pieces absolutely parallel when the screws are tightened up. Jig would have had push adjustment screws, probably 3 or 5, to get the pressure and slide resistance just so before the screws were tightened up, carefully and bit by bit in sequence. Locating pin holes fitted next in self jigging process.

Fast, simple, reliable and very effective on the production line. With only two fixing screws your chances of getting it just so are slim to none. Fitting a third screw in the middle might make free hand assembly to "just so" standards possible. But I have worked on a system of that style with three screws. It was still aright PIA getting from "almost OK" to "dead nuts". That said I think the system I worked on was only intended to be pretty good not dead nuts.

No practical experience of setting / locating jigs in that sort of application but I have assembled things that pretty much worked in the same way as that sort of jig would and getting it right was pretty much a breeze.

For setting jig think square hole in thick plate received to clear the male dovetail with pusher screws to align the loose dovetail. Best made by careful machining with an accurately flat side sitting against the fixed dovetail but I've little doubt that something cruder with screws both sides could be got to work just fine.. Take 5 times a long tho'. You will need a smooth, fairly thick shim between the side of the loose dovetail and the pusher screws so the dovetail moves smoothly without friction or twist as the screws pull it into place. Pins go in after screws are tight. You may have to re-drill.

Regrettably its one of these things that takes three goes to get the technique just so and fine tune the equipment before it becomes fast and easy to do.

Clive.

2 February 2019 at 12:18 #394333Chris R 1

Participant@chrisr1Wouldn't it need springs

? It's tight in one part of the length and OK at another. My nagging question – how did that happen?

? It's tight in one part of the length and OK at another. My nagging question – how did that happen?If I tap a razor blade into the join to separate the bronzy side piece, do you think it will go back in the same position, as set by the pins?

I suppose the pins might be "riveted" to some extent. I mean plastically deformed such that they would 't work again if pulled out, unless hammered/pressed back. They aren't roll pins..

2 February 2019 at 12:56 #394347 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Hello Chris

I sent you a personal message this morning … as yet unread

MichaelG.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Beginners questions › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

quality 3 and 4 jaw chucks

Started by:

Steve Huckins

in: Workshop Tools and Tooling

Steve Huckins

in: Workshop Tools and Tooling

- 4

- 5

-

8 August 2025 at 09:49

Steve Huckins

Steve Huckins

-

Obscure Thread

Started by:

simondavies3 in: Hints And Tips for model engineers

- 4

- 7

-

8 August 2025 at 09:47

simondavies3

-

The strange phenomenon of Liquid Death

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 1

- 2

-

8 August 2025 at 09:35

Michael Gilligan

Michael Gilligan

-

Just How Many File Types Do We Need?

Started by:

Nigel Graham 2 in: The Tea Room

- 5

- 5

-

8 August 2025 at 08:39

John Haine

-

Boiler hydraulic test 4 hours

1

2

Started by:

endckr111 in: Stationary engines

- 13

- 34

-

7 August 2025 at 22:48

endckr111

-

MD65 leadscrew cross-slide stuck in nut

Started by:

leov

in: Manual machine tools

leov

in: Manual machine tools

- 9

- 20

-

7 August 2025 at 20:54

old mart

-

Fobco or a Clarke CMD 1225 milling capabilities? or other recommendations?

Started by:

jacobsmess in: Workshop Tools and Tooling

- 4

- 15

-

7 August 2025 at 20:46

jacobsmess

-

Arc Euro Trade Ltd.

1

2

3

Started by:

Ketan Swali in: General Questions

- 55

- 66

-

7 August 2025 at 20:07

andy198712

-

Model Turbines

1

2

…

24

25

Started by:

Turbine Guy in: Stationary engines

- 28

- 611

-

7 August 2025 at 16:44

Turbine Guy

-

Pragotron Slave Clock

Started by:

renardiere7 in: Clocks and Scientific Instruments

- 7

- 18

-

7 August 2025 at 16:28

renardiere7

-

Miniature parts maker in Leicester?

Started by:

wilson logan 1 in: Help and Assistance! (Offered or Wanted)

- 2

- 2

-

7 August 2025 at 16:11

Michael Gilligan

Michael Gilligan

-

Pratt Bernard Grip true issues

Started by:

teamricky in: Workshop Tools and Tooling

- 7

- 11

-

7 August 2025 at 16:04

teamricky

-

Will iron rivets expand to fill oversized hole?

Started by:

Arthur Jones 2 in: Locomotives

- 6

- 8

-

7 August 2025 at 14:41

parovoz

-

UK Steel Supplier? 125 x 125 x 50 BMS

1

2

Started by:

MarkS

in: General Questions

MarkS

in: General Questions

- 14

- 29

-

7 August 2025 at 14:03

Journeyman

-

DELL / StarTech [mechanical incompatibilty]

Started by:

Michael Gilligan

in: Electronics in the Workshop

Michael Gilligan

in: Electronics in the Workshop

- 3

- 11

-

7 August 2025 at 13:11

Michael Gilligan

Michael Gilligan

-

Rotary table Chuck mounting.

Started by:

John Gray 7 in: General Questions

- 8

- 10

-

7 August 2025 at 12:31

JasonB

JasonB

-

Boiler Design – issue 4765

1

2

…

10

11

Started by:

Charles Lamont in: Model Engineer & Workshop

- 29

- 260

-

7 August 2025 at 11:18

JasonB

JasonB

-

Baumann Buco 1311 clock

Started by:

Clock polisher in: General Questions

- 1

- 1

-

7 August 2025 at 11:10

Clock polisher

-

New member (a young’un)

Started by:

tomread12 in: Introduce Yourself – New members start here!

- 7

- 8

-

7 August 2025 at 10:39

parovoz

-

Pre-Setting 4-Jaw Chucks Hack for Quick Centering

Started by:

dbwjbp in: Workshop Techniques

- 11

- 12

-

7 August 2025 at 10:06

noel shelley

-

Bandsaw vs Powered Hacksaw vs Chop Saw?

Started by:

MarkS

in: General Questions

MarkS

in: General Questions

- 18

- 23

-

6 August 2025 at 21:53

grubscrew

-

Fobco Star (Universal) Milling capabilities? or a Clarke CMD 1225?

Started by:

jacobsmess in: Workshop Tools and Tooling

- 1

- 1

-

6 August 2025 at 21:26

jacobsmess

-

Save your Swarf!

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 9

- 9

-

6 August 2025 at 21:12

Grizzly bear

-

Depth of cut cowells me90

1

2

Started by:

kinross1 in: Manual machine tools

- 14

- 39

-

6 August 2025 at 18:39

Richard B

-

Help recommend a milling machine?

1

2

Started by:

richard1989 in: Beginners questions

- 21

- 33

-

6 August 2025 at 13:50

Pete

-

quality 3 and 4 jaw chucks

-

Latest Issue

Newsletter Sign-up

Latest Replies

- quality 3 and 4 jaw chucks

- Obscure Thread

- The strange phenomenon of Liquid Death

- Just How Many File Types Do We Need?

- Boiler hydraulic test 4 hours

- MD65 leadscrew cross-slide stuck in nut

- Fobco or a Clarke CMD 1225 milling capabilities? or other recommendations?

- Arc Euro Trade Ltd.

- Model Turbines

- Pragotron Slave Clock