Thats a nice little milling machine, AEW Viceroy / Horizon. The motor in your pictures will convert to delta for a VFD just fine.

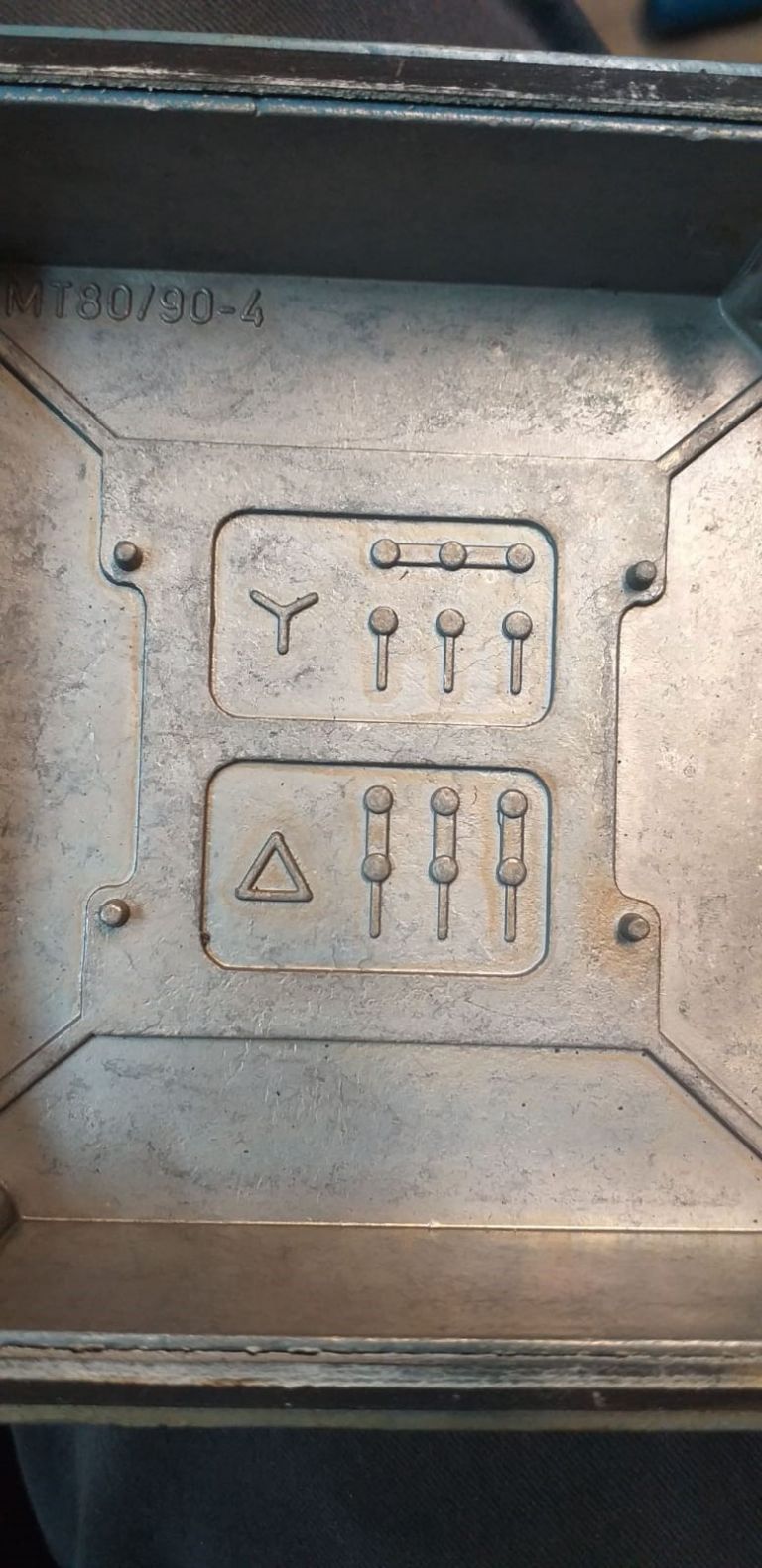

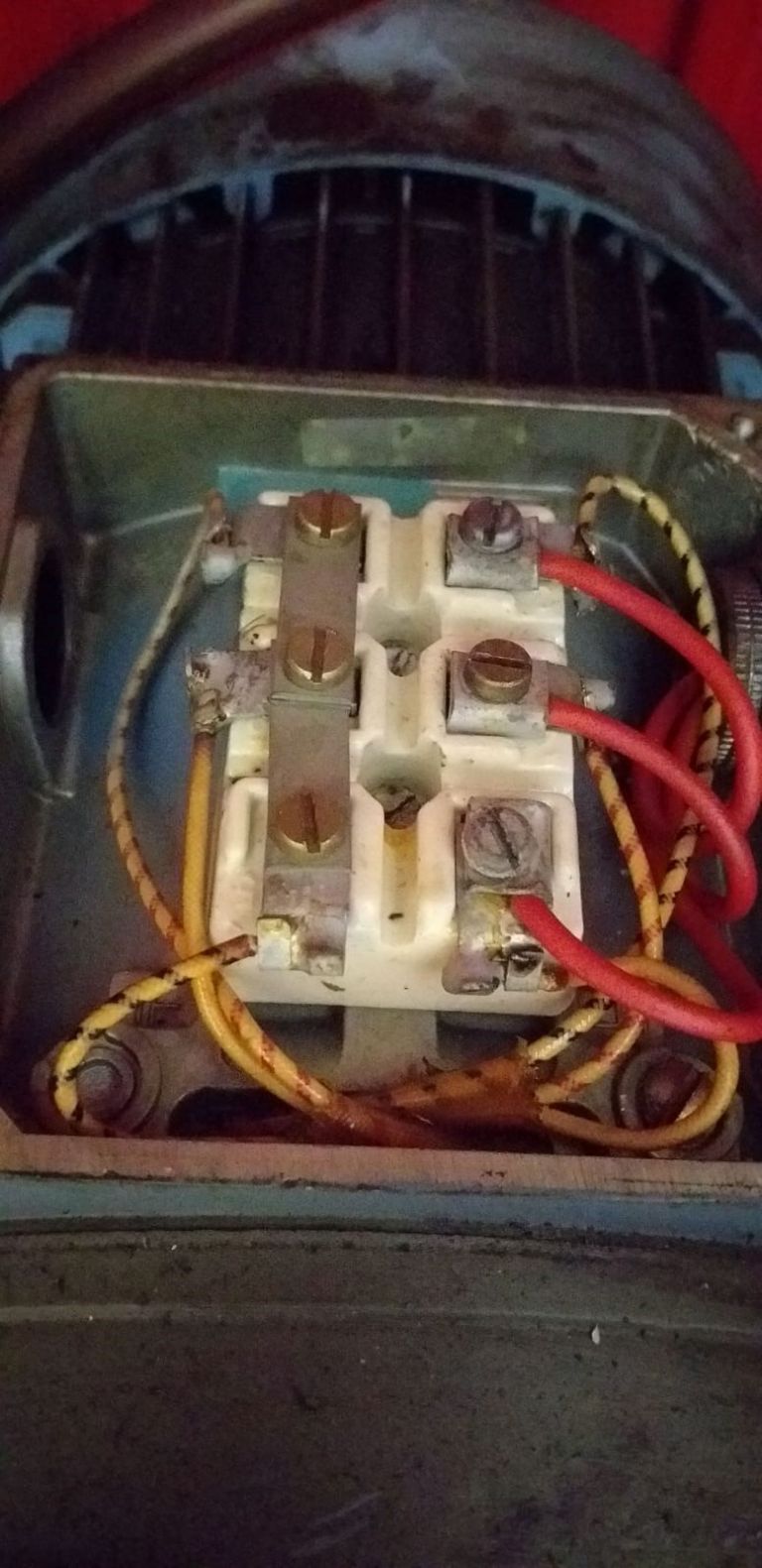

I see why a converter was used. Two motors. 2 hp on the spindle and 1/3 rd hp on the power feed I think.

Conventional wisdom is that VFD boxes should be used one per motor to avoid large power variations, switching issues and things likely to get their electronic knickers in a twist. More so with modern ones which tune themselves to the motor as an effective way of improving the speed range over which the power holds up well.

However I think it possible that my favourite, for simple installations, Eaton DE1 series can cope with two motors as they are supplied as a simple alternative to old style contactor controls and are more tolerant of "less than ideal" fitting. Its possible that the 2.2 kW version (£140) has the overload capability to handle the power feed motor being switched in with the main motor running otherwise you'd need the 1.5 kW version (£121) for the main motor and the 0.25 kW (£65) version for the power feed. Always assuming the feed motor can be connected delta too.

See **LINK** for the Eaton range.

I'd contact Inverter Drive Supermarket and ask what they suggest. I've no affiliation but have had good service myself and they have a stellar reputation for helping folks who don't know much about such things to make a good choice.

If going for two VFD boxes you may be able to do it more cheaply but best to avoid anything that doesn't have a proper English manual or UK native back up. IDS do wonderful easy set-up guides for some of the ones they sell.

Clive

Clive Foster.