Posted by Wolfie on 23/01/2012 18:51:53:

OK well finally got round to having a go at this. Not assisted by the fact that the parts are so small and difficult to hold……………………..

3rd time I might have managed it but I’m not trying to force it off, should I??………………..

And how do I clean off all that black clag?

Hi Wolfie,

Yes you should try to pull it off, if you can do it by hand then it will not stand up to the forces involved when the engine is running.

To clean off the ‘black clag’ – if it is glassy it is molten flux. Easiest is to use mechanical means (the corner of an old file) at first then pickle in acid. If just oxide, clean off with emery.

By ‘pickle’ I mean soak in acid solution, I use citric acid, safe, quick and cheap. Get the crystals from your pharmacist or grocer and make them up into a reasonable strong solution. Be aware that if you have iron or steel with copper alloys (eg brass) there will be a minor reaction and there will be future deposits of copper on brass.

1) – For successful soldering both parts need to be scrupulously clean and well fluxed before assembly.

2) – Do not overheat otherwise the flux will be ‘aged’ and not work.

3) – Put a scrap of solder in place before heating, when the flux ‘boils’, have a length of soft iron wire (florists wire) to push it back into place before it reaches melting point.

4) – Make sure that both parts are heated equally,

5) – if successful the solder will run into the joint by capillary action, it is a great feeling when it does.

Also, do not use too large a torch for such small parts, a ‘cooks torch’ will be sufficient for such a small job. Remember, solder will follow the heat.

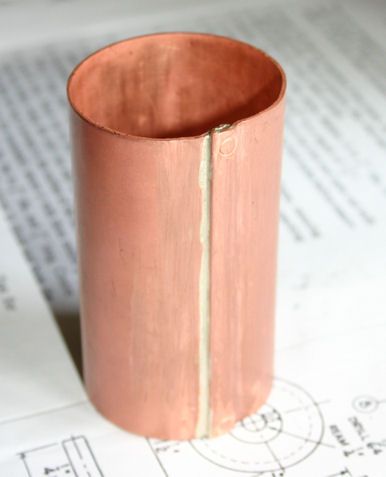

This fabricated boiler tube was pickled in citric acid after soldering, dunked when still warm, not hot – 20 to 30 mins –

Edited By Terryd on 24/01/2012 22:03:53

John Rutzen.

(students!). Some things are almost impossible to acheive without using this technique such as making a hinged lid using chenier tubing. Applying solder to this in any other way usually results in flooding and a solid mass no loner a hinge.

(students!). Some things are almost impossible to acheive without using this technique such as making a hinged lid using chenier tubing. Applying solder to this in any other way usually results in flooding and a solid mass no loner a hinge.