So impressed was I with that lashup I've knocked up a dedicated hacksaw

It needed to be narrower to fit into the work envelope of the machine but the duty cycle of a small shaper is 24/7 and you can simply walk away and do summat else, returning every 5-10 mins

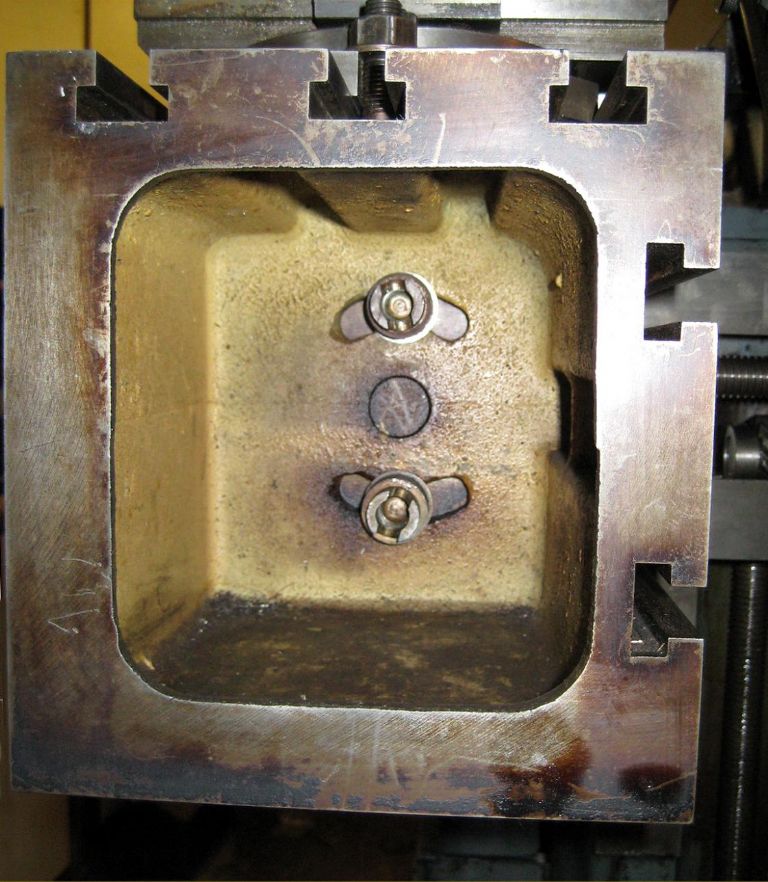

A 10 mm roundbar has a 12mm squarebar at each end. On the end on the squarebar is the gubbins for the blade which is simply me copying a proper hacksaw, everything has been welded together

I broke 2 new blades testing for the best cutting direction, 2 beautiful eclipse blades! I thought that the draw stroke would be better than the push stroke but no, the push stroke worked best, the CRITICAL bit is that the blade just lifts at the end of the push stroke (via the clapper) and lifts the blade slightly for the backstroke. You can see how the saw hangs downwards from right to left

You can watch this "lift" increase as the blade cuts through the workpiece and you screw down the topslide to work your way through a bigger job

Eclipse blades are incredibly strong and durable, you can see how the 10mm roundbar has become bowed by the amount of pressure one can handle as I tightened the blade up

Only a light weight is needed, as can be seen from the molegrips hanging from the end. The shaper is on the next speed up from "slowest" which is plenty fast enough for my liking, a wee dod of oil on the cut at the start keeps things smoother for the session

Cut accuracy is only medium, I would say that you would need a system of enclosing and gripping the blade in a vice type cover at each end to stop it flexing while it works, mounting pins alone are not sufficient

Does a great job of cutting stuff up tho

Edited By Ady1 on 21/03/2015 11:53:38

Ady1.

Ady1.