Dave, personally I'd go for the smaller ER25 collet chuck than the one Oldmart linked to, as it's just less cumbersome as well as being cheaper.

A less expensive one to that which I linked to earlier, is available from Chronos, but I've no idea of the quality; they also supply it in a kit with collets, if you don't have any already. This looks to be a one piece version with no machining to complete. Either would then fit onto an MT2 arbor with a pre cut Myford spindle nose. I have one of these as well as a parallel to Myford arbour. The latter might make tool sharpening easier too, should you ever obtain a tool cutter grinder.

If I was in your position, I wouldn't modify either the mill spindle, or your Clarkson Chuck. Since you've got a Myford, the ER chuck I linked to earlier would seem the best option, if finances allow.

Looking at your earlier photo, I'd say your spindle has both the Myford thread as well as the circular register behind/above it. Certainly that was the original design. I've even used a conventional, Myford fit, 3&4 jaw chuck on the mill to hold a large fly cutter.

I'd certainly look to getting one with a ball race closing nut, rather than a plain one, as shown in that link. Collets for the C Type do come up on ebay and at car boot sales/autojumbles. Note, they are not interchangeable with either the S Type or Osborn ones.

My chuck came with just imperial collets; so to start with, I made my own metric set, even those are 20TPI, so a 1/4", 3/8", and 1/2" imperial taps were used to cut the threads in the 6mm, 10mm and 12mm. I was struggling for something to use for a 16mm 20TPI, so in the short term I used a plain home made collet until a proper 16mm one turned up at a steam rally.

Apologies for the poor photos to follow, but they were just quick grab shots, as we're off out to Wetherspoons for a curry soon.

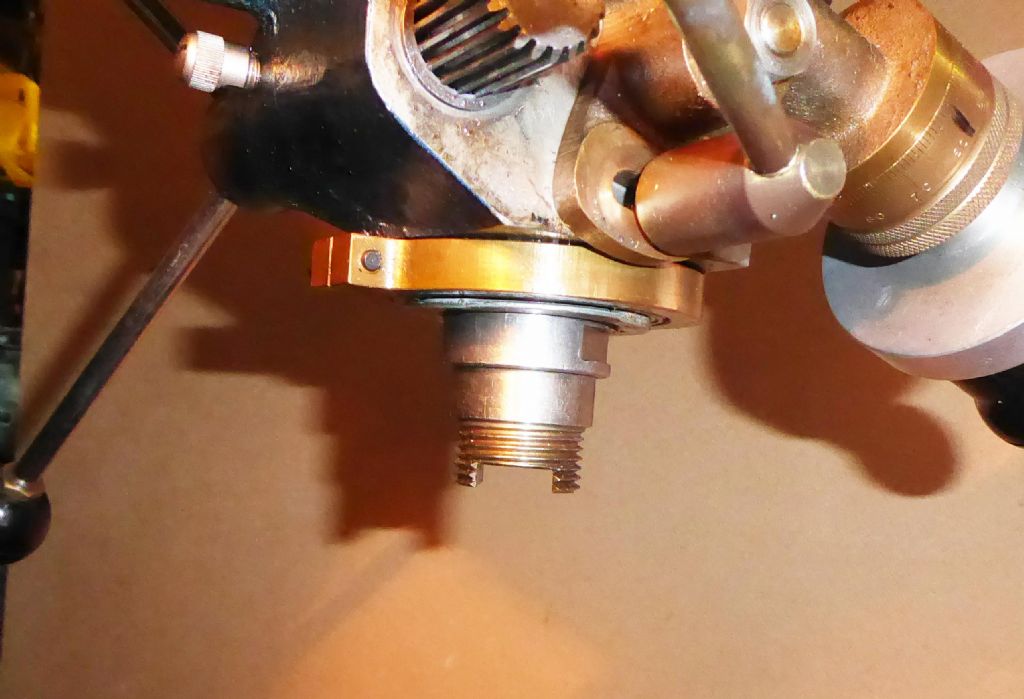

Here's my version of the Clarkson C type with the left handed nut at the top.

Note the little slug at the left hand end. It's 3/8" WW external to fit the drawbar hole in the taper, with a 6mm hole in it to fit the smaller draw bar in the DW mill spindle. I also have a 6mm/10mm one to allow the use of cheaper imported MT2 blanks, which come tapped M10, rather than 3/8.

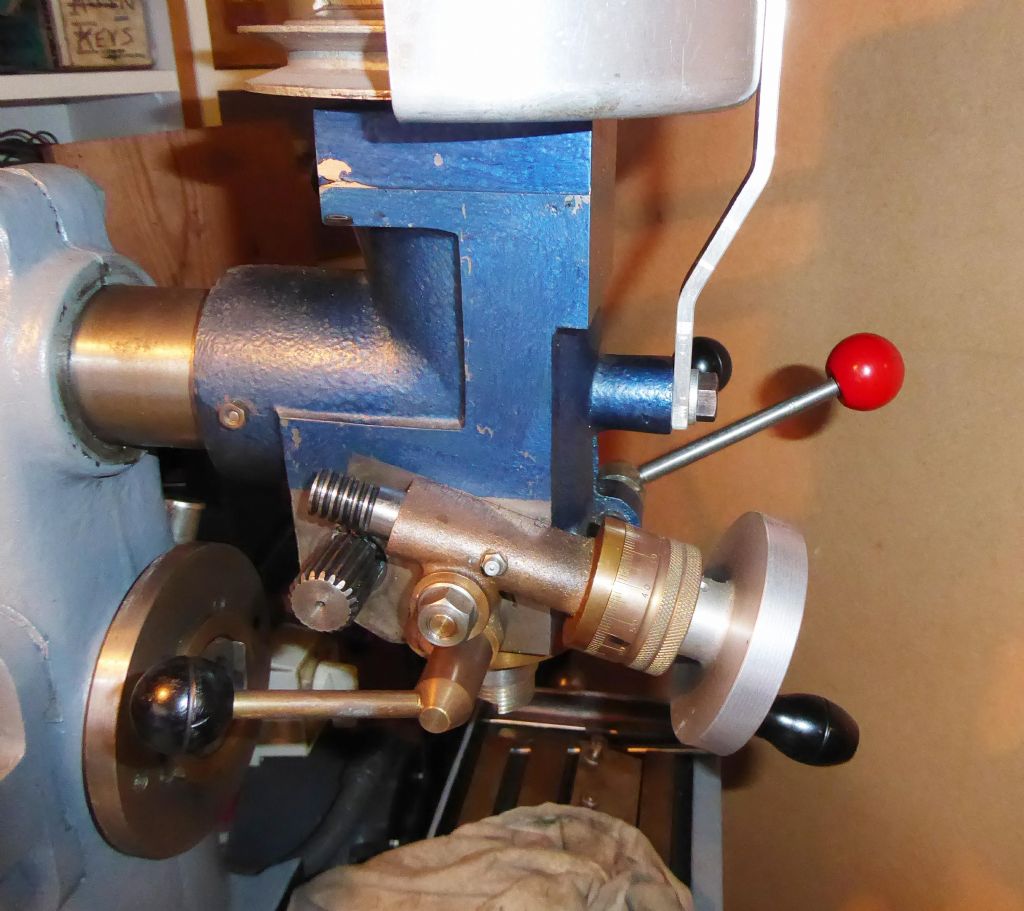

And fitted to my DW mill, with the nut removed as it's just a bit too thick for this application.;

Next for a height comparison, the same 10mm threaded Clarkson cutter in an MT2 ER25 holder.

Followed up with the ER25 collet holder on a Myford nose; in this case a Warco 720 Super 7 copy.

And on the mill

Just for comparison, the same mill in an MT2 Clarkson S Type, the release nut just fits on this one.

And an MT2 Osborn Titanic

The ER chucks and the Clarkson C Type will hold plain shank cutters without modification, The S Type and the Osborn need a little slug making to enable the chuck to tighten up the collet on the shank of the mill.

All will hold threaded end mills, but only the ER type will easily hold double ended ones.

Bill

Edited By peak4 on 24/10/2019 21:25:55

Nigel McBurney 1.

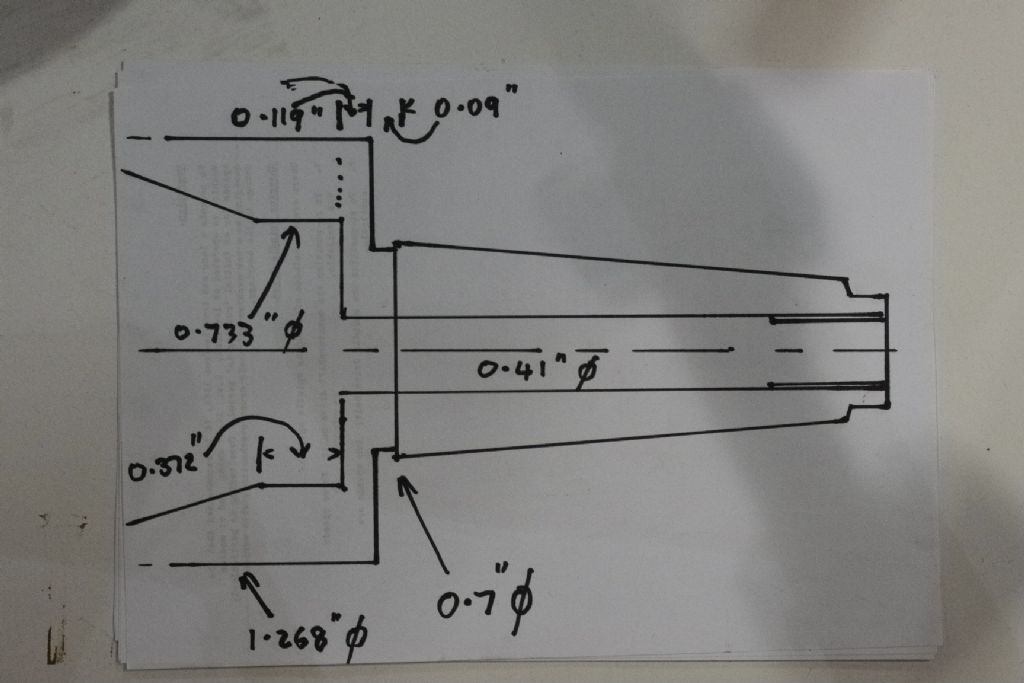

that fit the the flats on my chuck. This means that the female taper starts inside the quill beyond the length of those two 'dogs'. A standard MT2 ER chuck taper will be prevented from mating fully because the dogs will strike the back of a standard ER chuck. before the taper mates, requiring those flats to be added to the chuck.

that fit the the flats on my chuck. This means that the female taper starts inside the quill beyond the length of those two 'dogs'. A standard MT2 ER chuck taper will be prevented from mating fully because the dogs will strike the back of a standard ER chuck. before the taper mates, requiring those flats to be added to the chuck.