i've just bought a second hand cold cut saw, so i may never have to part in the lathe again… it's one of those that spins the blade at 85 rpm's and pumps coolant over the blade when it is turning, a nice upgrade to my abrasive wheel type cut off saw,

And hopefully much cleaner than the evolution rage type i was thinking of getting, the ones that use a tct blade spinning at a few thousand rpm's (can't believe the little ones that cost about £100 spins the185mm blade at 4500 rpm!)

Unfortunately if i were to use a hacksaw to cut the 2 inch piece of steel round bar, i'd not be able to do anything for a week whilst my joints recovered (arthritis) hence my reliance on power tools,

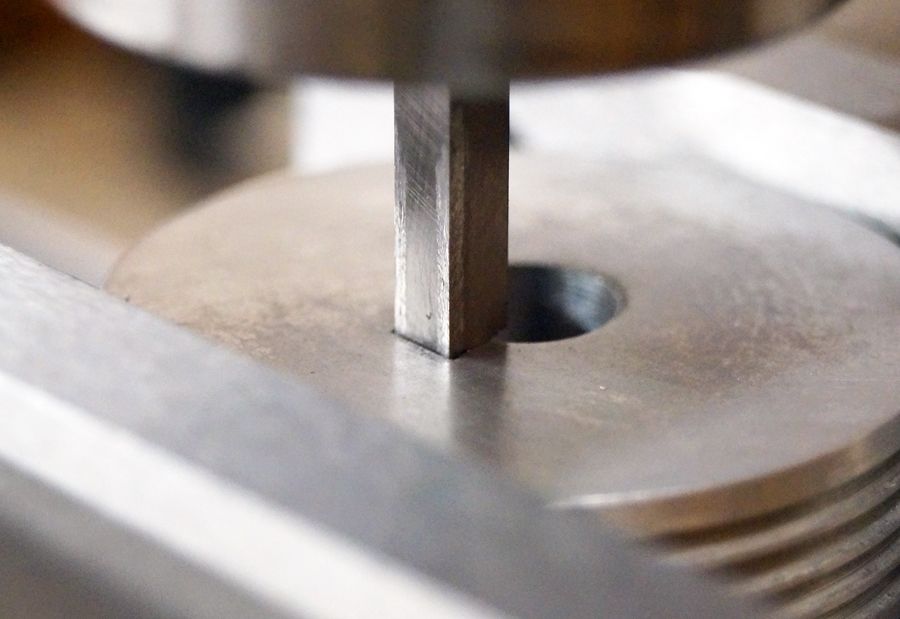

But i still will part little things on the lathe… i just bought that nice new parting tool after all, just not steel, as i now know thats outside the capacity of this little toy lathe i have.

I did notice the compound slide was going to be an issue, so before i started parting i locked the gibs tight, but of course i couldnt do that to the cross slide and carriage… but i have recently (as in a few weeks ago) stripped and re-fitted all the moving parts of the lathe, so i have the gibs and that crappy excuse of a carriage adjuster as tight as i can have them whilst still allow them to move.

I do want to make tapered gibs for this lathe one day, but not having a milling machine or even a milling slide, i might struggle with manual tools to cut them, wish there were ready made tapered gibs i could buy and fit, but aparantly for the carriage one that needs some other mods, but anything's got to be better than the way it's held on atm.

I think it really was the interupted pressure on the parting tool that was at fault, i had one hand turning the cross slide handle, the other hand with a small brush slathering cutting oil in the grove it was cutting… which at the same time the brush was positioned just over the blade to stop the shower of hot chips going on my hand that was turning the handle (well shower of filings was more what i was getting, only when it dug in did i get some nice chips from it..and we know how that ended 😀

A power cross slide is something i often wish i had, i can remember years ago using a small battery drill with a hex key in the chuck and powering the compound with it when making a taper, but that was on delrin, which is what i'd mostly been playing with on this lathe, or alli bar, this was really the first bit or real metal i did anything with in it.

I've owned the lathe since 2011, but hardly used it, 5 of those years it spent in storage when i lived in a crappy house with not even a shed, so i've really not learnt much in the almost 10 years i've had it

Gazz.