Posted by Phil Whitley on 20/05/2018 19:18:37:

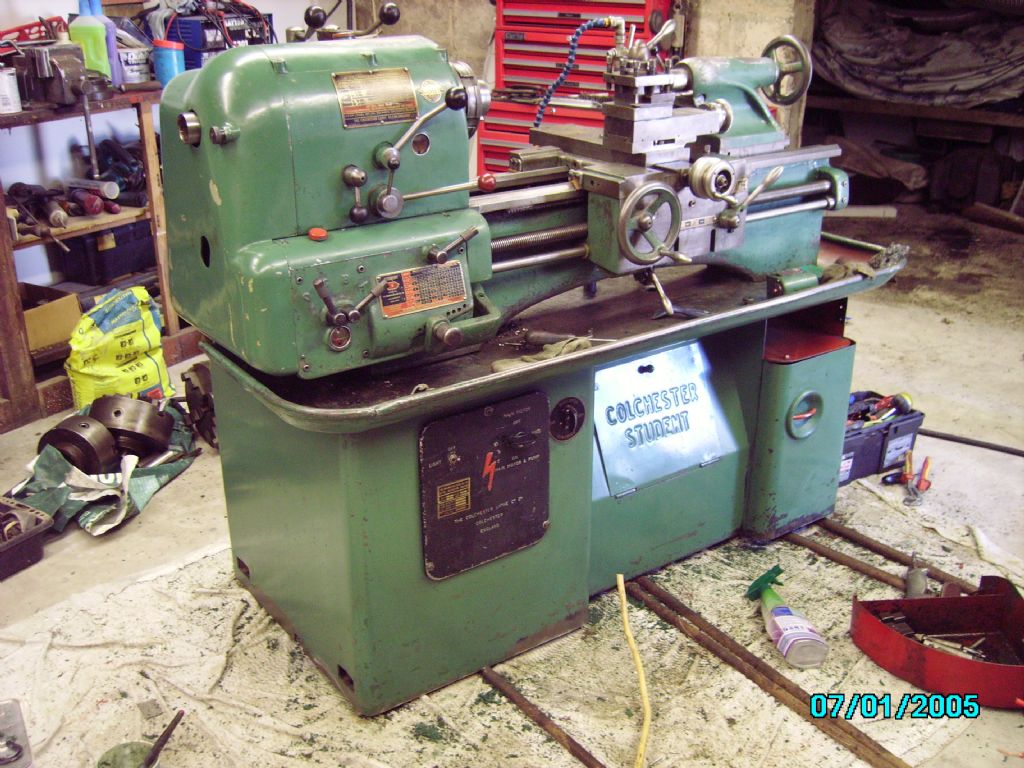

Forgot half of what I was going to say! Degreasing is of utmost importance, wash the paintwork down with a universal thinner (well ventilated areas only) and then get some of those little sponges with wet and dry abrasive on them and rub down with hot soapy water. the idea is to get back to the original paint surface. I would not try to remove all the paint, as you will also remove all the casting filler, and you will never get as good a surface as the factory did, unless you are willing to put in hours of painstaking work!! Having said that, the two hand positions (tailstock top and neadstock top) will probably have no paint on them anyway. Clean the holes and chips in the paint back to bare metal, then prime and stopper them with cellulose car stopper (put a teaspoon or so of thinners in the stopper every time you use it, to keep it soft), you will probably need two coats of stopper as the first will sink a bit and then blank out the repairs with primer, flat the whole thing, and top coat it. There is no need to prime everywhere, where you have good solid paint, just flat it and give it another top coat or two. How far do you want to go? originally they used an etch primer on the bare metal, as I did, and then stoppered on top of that, but every coat of stopper needs an overnight dry before you can flat it. You could use body filler, this sets hard quickly, but it is harder to flat too! I sprayed my lathe easily with 1L of paint, and have about 1/3 L of thinned paint left for the small bits like handwheels and thread counter.As you see from the pic, I didnt paint the saddle or apron. If you get a stanley blade, and tap it very carefully under the brass plates adjacent to the drivescrews, followed by a scraper , you will find that with a bit of care you can get the screws out, and the plates off, which save a lot of tricky masking. If you do go for masking, clean the edge of the plate. mask round the edge, then fold the masking onto the plate so that the edge of the plate is masked, BUT if you do this, you must very carefully remove the masking while the paint is still tacky, or you will damage the paint when you demask. I masked the plates on the neadstock, but took the plate off the screw cutting gearbox cover, and TBH, it was so easy to get off, if I did it again, I would take them all off!

Phil

I will re-read this again, thanks for the advice.

I wasn't aware that Colchester would have applied filler to the casting though perhaps I shouldn't be surprised.

Which paint did you use? I see Paragon suggest not using a primer as they claim their paint will adhere to clean bare ferrous surface.

The lather is dismantled in so far there is still the bedway, tray and cabinet so I can paint items like the apron etc off the lathe.

As I said to the other poster I was considering painting with a roller and brush, and now wondering if I ought to consider spraying.

Many thanks again for your time and assistance.

the artfull-codger.