Hi, Geof was searching for similar problem I have with chinese lathe, here is my story.

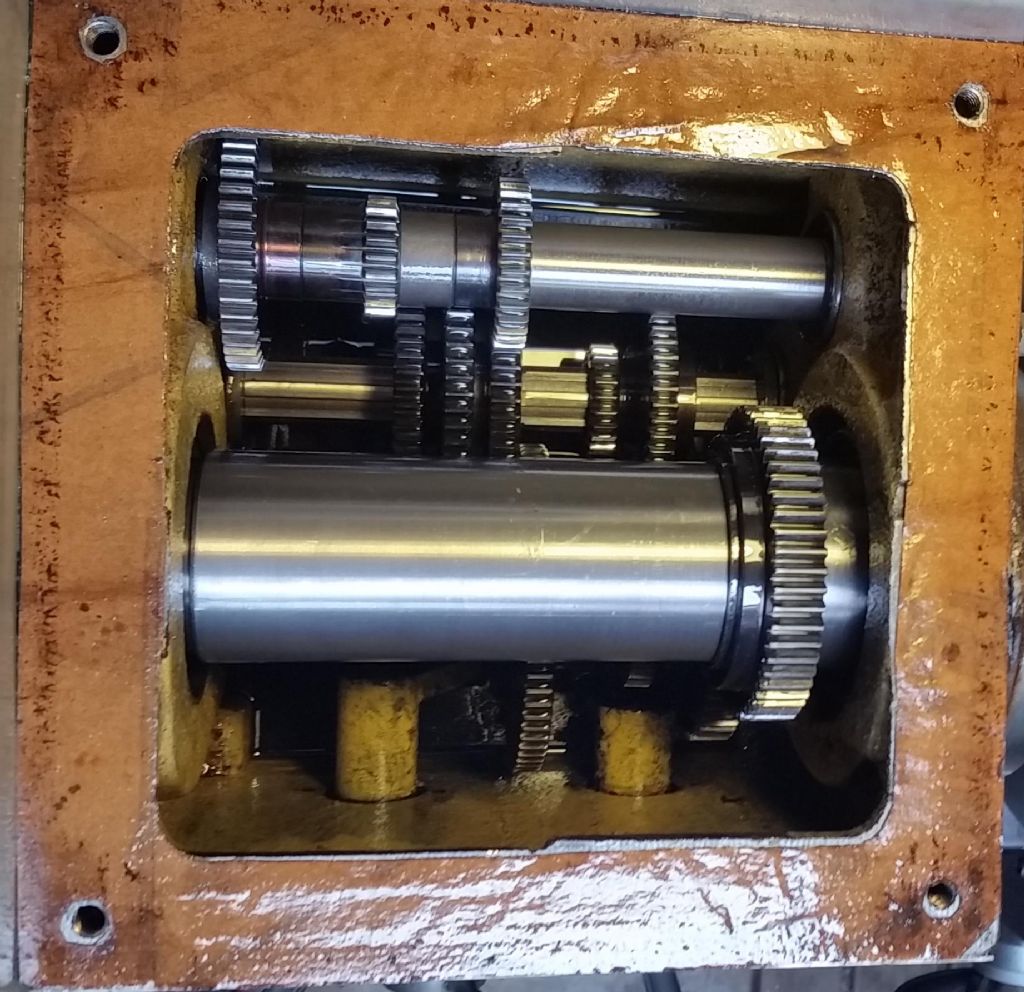

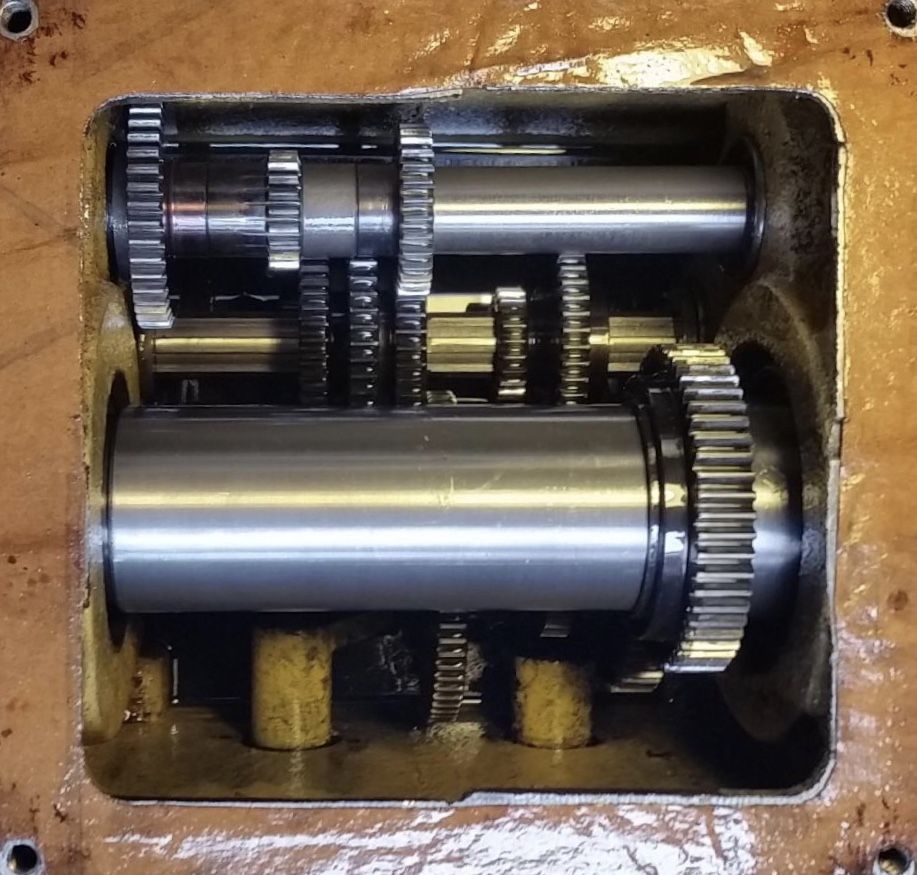

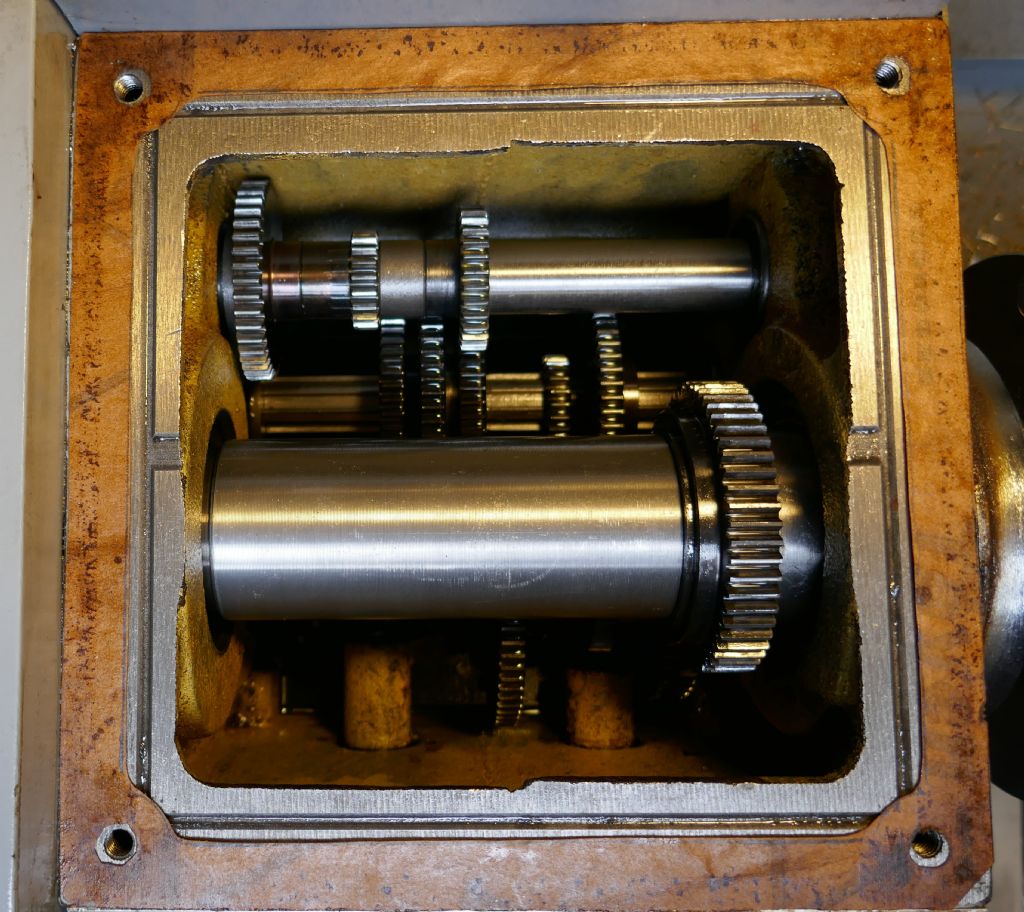

Gearhed Lathe:160mm Chuck 330mm swing.

Problem-1: I am sure spindle bearing not getting oil they deserve.

Problem-2: I would say its noisy in higher gears.

I did the following Before)

Before)

1-I sucked out oil, put in diff 90 oil. Within 10 minutes it was out again. Motor not strong enough to pull it through that oil viscosity, and motor may burn out as well. I did this a year ago.

Last week:

2-I made a wooden frame, had a 6mm glass 21x22cm cut and fit & sealed on wood frame as a lid, this gave me great insight into what is going on, I could clearly see how and where it splahes depending on gear choice as weel as running in reverse(Big diff in each case).

3- I could see the spindle bearings with holes on top, not groves like yours, dont get oils fast enogh and well enough no doubt.

———Catch plates—–

4- I then went on the following endeavor with great success using the glass as giude to see.

5- I decided on a ISO 68 oil Fuchs freely availably for me 5L at Farm Strore. I mixed this with a dark blue marine grease wich in my opinion mixes well with this oil, not all greases mix well I tried, I like this. In my opinion this keeps the oil light and gives a softness to it wich I like. To test I pour it through a seringe 20mm(contraption=3 Seriges) to compare with ISO 68 and no difference….It flows to halfway, then drips, other oils like 30SAE behaves differently.

6-Ok so now I filled the gearbox higher, above glass to get a good throw on low speed gear (60 RPM).

—-New design………I am busy making "catchplates" from aliminium about 15mm wide.

7-I 1st made one to cross the top section with a bow in the middle, lets say 3 degrees to middle. This plate now catches the splashes, I grinded a groove in 3mm plate. You wont believe how the oil now flows towards the spindle bearing holes on bth sides. I even grinded short groves going sideays to direct overflows back in gearbox. This works perfect for all gears except the two lower speed gears, so I added more catch aliminium to catch from where the oil lands on glass, then drips down on catchplate and fow to spindle bearings. This worked, but not good and fast enough to my expectation, so I further improved this method on topside.

8-I then went further, seeing I can see everythinh happenning clearly. I went down in the greabox, fit a cross plate above a gear splashing, wanting to splash upwards. I construct this in such a way that it takes useseless splash from another gear below, let that oil flow left to this gear and shoot it upwards, not the catchplate catch it and I am very happy how fast the spindle gets oilflow in two lowest gears (60 & 90 rpm).

9-I am now going further, remeber I filled the gearbox a bit more oil, I would say 1/3rd. In higher gears motor stayed cool, I did not noticed drag, the gears are not wide to begin with, maybe that helped. This oil and grease combo is not "heavy", I liked that.

10-At moment I m busy with final design/idea to implement, and that is Drain-Reservoirs, to catch surplus oil in higher gears and "store" it, dripping away when the rush is over, keeping less oil in circulation momentararly, thats my theory in any case.

Note:Tomorrow I am going to extend "reservoir" on lower plate to store excess oil catched for upwards shooting gear. I will see if I can take a photo of the plot. So far I am very happy, and never thought I even do this.

Lathe is running quieter as well.

Chris Mate.

Before)

Before)