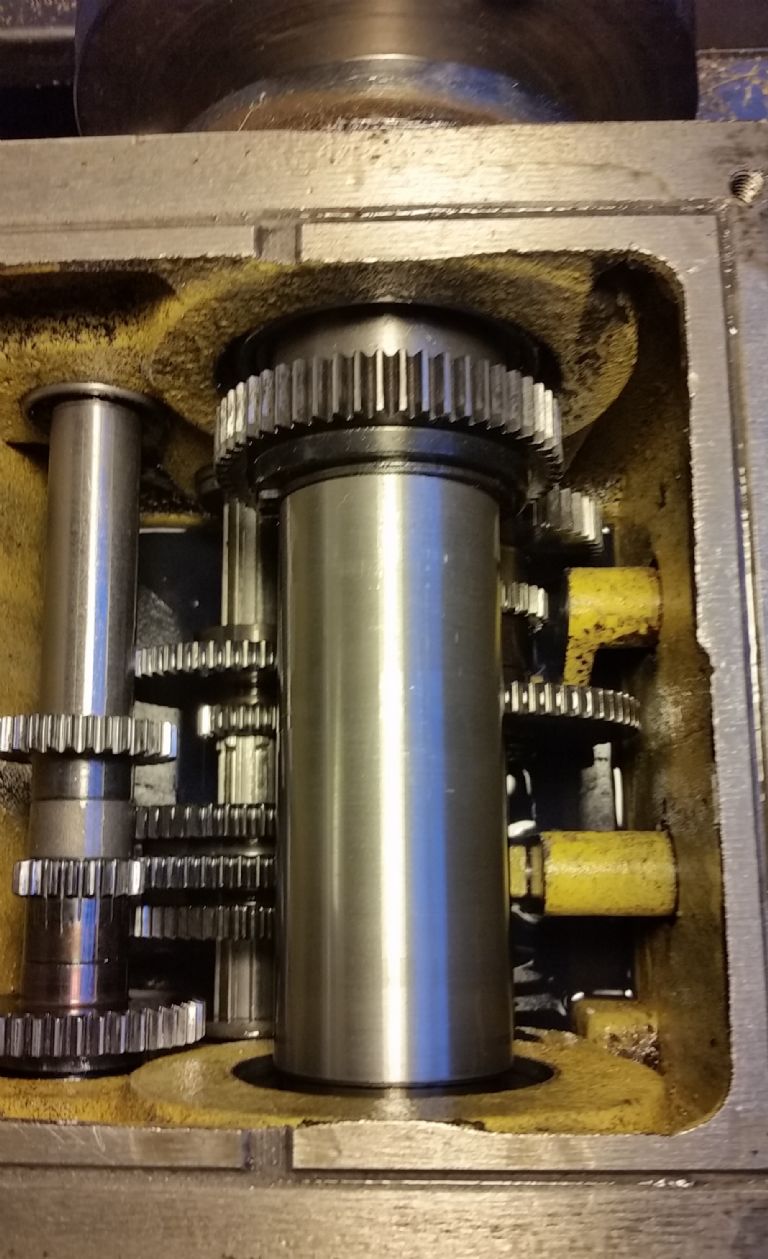

I bought a Myford 280 with a noisy gearbox, one of the interference fit gears had come loose and could slide left and right (correction, it could slide left, it shouldve been up against a shoulder on its right), I rebuilt the gearbox and there wasn't anything else wrong I could see (correction, something else was wrong, I don't recall what but you could "rub" gears together by pushing the selectors in certain directions, something wasn't aligned or secured or something). I used dab of special Loctite for very close fitting parts requiring a high bond while immersed in oil. It's smooth and has been whispering along for years now.

(The gear top left should have been against that shoulder)

I also recall the spindle bearings (Gamet Super Precision) required an end float of a 10th of thou off the top of my head (2um ish) and it was probably 5 times that although I couldn't see or feel anything moving! it was such a small number I'm sure even the 1000lbs of casting could flex that much if I pulled and pushed them!!

I think we need to know what lathe you've got, and if the noise is related to the input or output speed of the machine. I can see from that photo you have 3 ratios that you can transmit from the input shaft the layshaft under it but It's unclear to me what happens after that, I'm guessing another 3 position selector and perhaps a seperate backgear but I don't count enough gears or envisage enough throw on the selector for that to work, more info needed.

Where are you located, if you're local I could take a look/listen which counts for more than a thousand words!

Edited By Russ B on 05/02/2020 14:41:49

Chris Mate.