The saga continues…..

Today I had a first look proper at the motor swap.

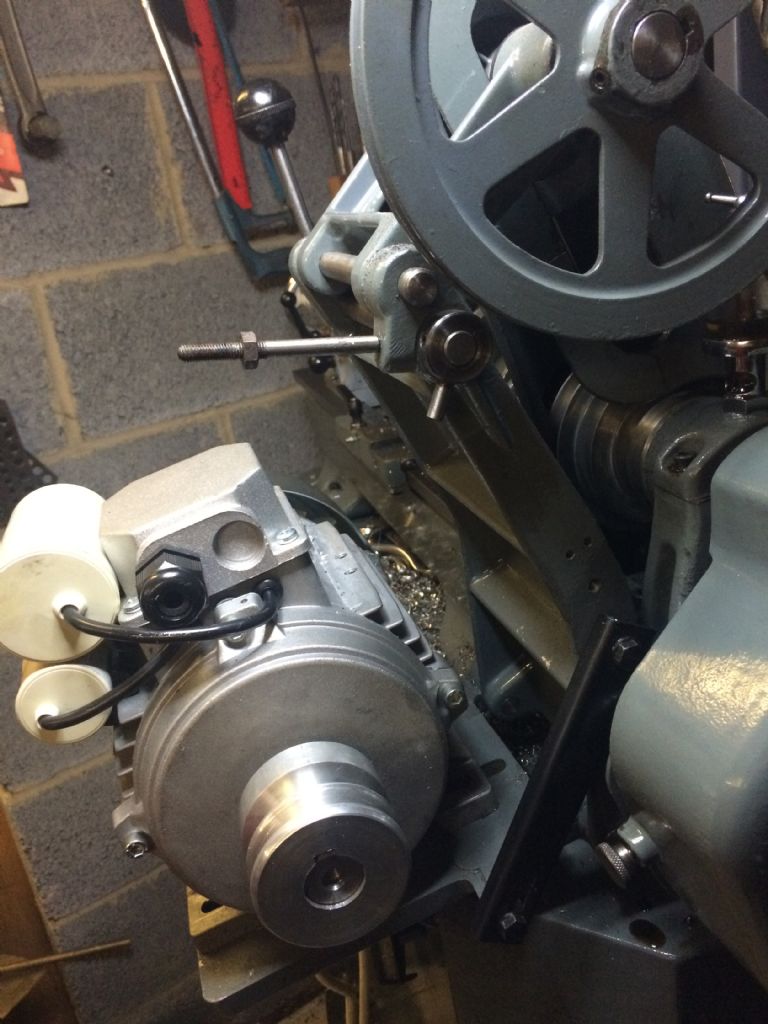

So the belt guard came off, and the old motor that looks like it belongs on my old mums twin tub, and the first thing to notice to everyone's great amusement I hope is that whilst the spindle shaft to layshaft belts are indeed A section V belt, the motor to lay-shaft pulley are not. They are SPZ size, a narrow belt (mine is 900mm long).

This is a little bit of an issue as my home crafted pulley is cut for the slightly bigger A size. I wondered why Myford did that, instead of using two the same, then I remembered they went bust in 2011.

Remember my pulley was left wide on purpose? Well it now has a second V groove, SPZ width. I also trimmed the overall width to get a good belt alignment with a straight edge and a number one eyeball.

The motor is temporarily on the motor hanger, with two bolts (I could only find two long enough today, Sunday, as the original motor mount was tin and the new one is thicker cast aluminium). The original 900mm belt is now of course too short, so I have ordered one each at 987mm and 1000mm as I think either will do but at only £4 each from Bearing Station on-line I'd like to have the choice. Once again I play the waiting game with the postman….

Meanwhile I now have a Super 7 tail-stock, which seems very nice and self ejects. I will need to check alignment when the motor job is done. I put a shiny new hand wheel on it as the original had lost a lot of plating, so it looks good too. I also now have my own set of adjustable reamers so I don't need to borrow one again. The motor is capacitor start and capacitor run as you can see.

Well till the belts come, that's it. Going to Alexandra Palace on Saturday, beautiful wife says that she'd like to go with me, probably to keep a check on any spending. If you are going, you can't miss me, I'm the middle aged bloke with a bit too much weight and glasses.

Edited By Richard Prentice on 11/01/2015 16:42:13

Richard Prentice.