Hi expert Myford types, I am very new to Myford ownership, and am probably the worlds least good metal turner. I live near Nottingham, and don't know anyone else with one. I mostly use my lathe to make nuts and bolts and spacers etc for my motorbikes. I've had a very short bed non screwcutting lathe for some 20 years or more of unknown make or origin, but it has a 3mt tailstock and a 4" chuck. I think the polite term for me is self taught, badly.

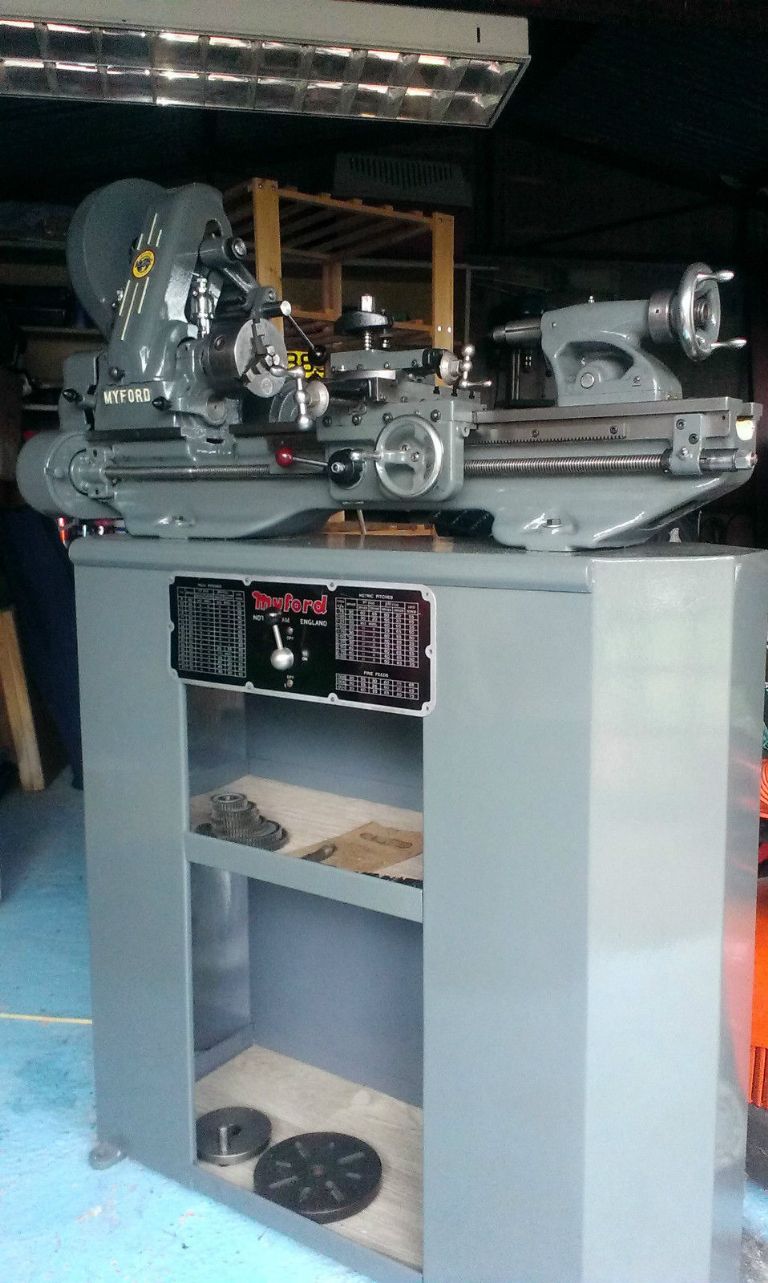

I now also have (kept the old lathe too) a 1955 M7 that seems in pretty good condition that I want to ask about. Mine has a Dewhurst type switch, that does forward-off-forward ie no backwards. It also has V belts, running from a single phase 1/2 HP motor with a 2" motor pulley, giving exactly 500 rpm as max speed at the chuck. The oilers on the spindle are the see through Adams type, and seem to work fine unless I forget to close them when they will empty overnight.

Having been used the other lathe the Myford seems a bit underpowered, and although the belts don't slip, it's quite easy to stall the chuck on anything but a very small cut. Most of the things I make are stainless, and hardness seems to vary a fair bit. I am using indexable tools on a Myford quick release tool post. The moderately slow top speed makes a good fine finish hard to get in my humble opinion.

I'd like to up the motor HP and I now have a 1 1/2 HP (don't laugh I was going to put a 2HP on) Italian motor that is brand new, running at 1429 rpm and 4 pole so I am able to wire it to forward/reverse which I think would be handy. I have not fitted it yet. The output shaft of this motor is keyed (8mm) with a 24mm diameter. The original motor is 5/8" and therefore I propose to up the motor pulley to 2 1/2 inches to give a bit higher top speed, the bigger motor will produce rather more torque.

I've ordered a new 2 1/2" pulley but it is 3/4" bore so I will open it up to 24mm. I don't have a broaching set and they seem a bit dear for a single use at this time so I propose to use the grub screw provided and see how it feels.

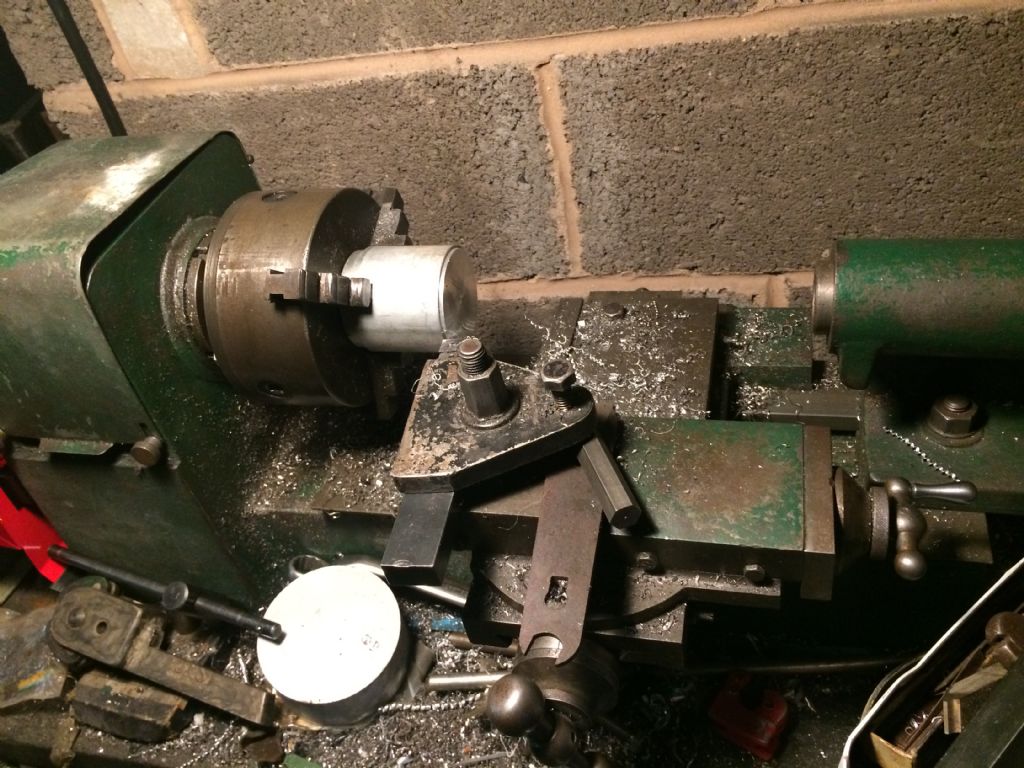

If I don't like the bored pulley I will make one from scratch from some 2 1/2" aluminium stock I have. I am quite brave and like a degree of experimentation so I have also ordered a 125mm 4 jaw self centering chuck as there are some items (like the 2 1/2" pulley blank) that won't fit in the standard 3" Myford PB chuck I have.

So if you have read this far without falling asleep, can anyone tell me if my proposals seem plausible, and let me know if there's anyone in my part of the world who has one of these lovely machines too? I am planning to have a day down at Chrystal Palace later this month for a look see.

Thank you

Richard Prentice.