I dont see where it says what the mini lathe gears' module number is, but if you contact Ketan at ArcEurotrade i am sure he can quote you chapter and verse on that stuff.

I would still try to figure out how to use the 20dp gears that you have. Is the gear on the main spindle 20dp? if so, and the last gear in the tumbler group is the same number of teeth, you have a 1:1 ratio, and may be able to mesh a 20dp gear with the inner gear of the compound pair and carry on in 20dp from there.

Or, you may have to make up a compound gear to go on that tumbler output stud with a gear that matches the main mandrel gear compounded with a 20 tooth 20dp gear. Your list of extra gears, I understand, includes a 30T and a 20T so if you mount these on a stud, pinned together and use them to replace the current compound tumbler output pair, you should be able to cut your thread with the 50T on the leadscrew and couple of idlers in between.

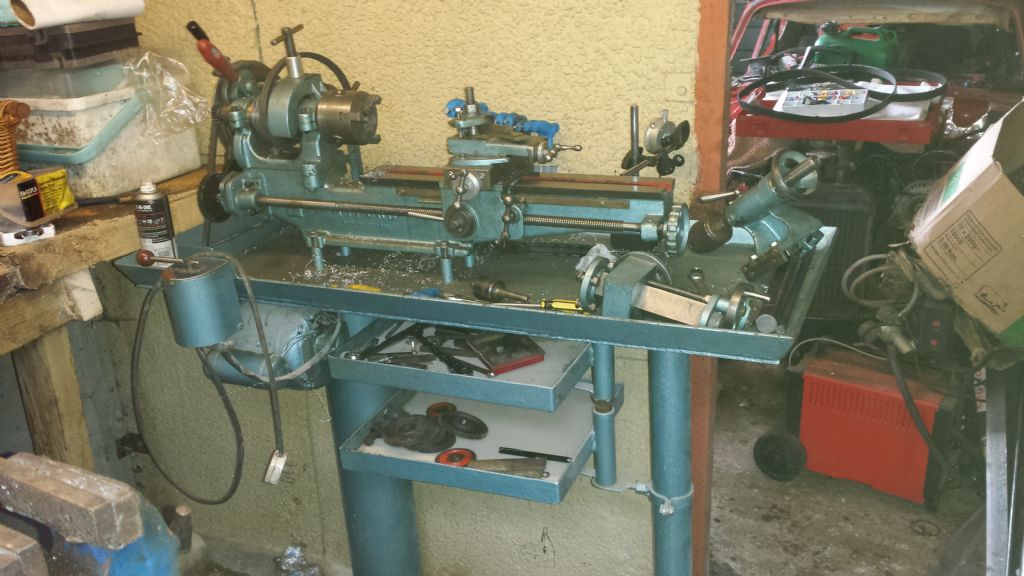

The more I look at that tumbler combined belt tensioner, the more intriguing it gets. It looks quite possible that the old engineer had the belt tension handle right there next to the reverse tumbler so the belt tensioner could be used as a clutch to disengage drive before shifting the tumbler from forward feed direction to reverse, then re-engage the belt. Much quicker than stopping the motor, changing tumbler and restarting etc.

And if your 20t 20dp will not fit over the diameter of the main spindle, your lathe may have been fitted with a larger than standard spindle, with larger bearings and a larger hole down the middle. All very advantageous.

Jet engines eh? A look into the making of jet engines may reveal more about what goes on that rather special vertical slide. Machining turbine blades is rather specialized and maybe this was the gizmo used.

Edited By Hopper on 27/05/2016 09:58:58

Edited By Hopper on 27/05/2016 09:59:59

John Fielding.