Sam

Back around 2005 or thereabouts I planned to make a tool & cutter grinder and did a fairly comprehensive literature survey to find something combining a decent range of capabilities with a reasonably short build time.

Ruling out the Quorn before even starting the list due to its notoriously long build time combined with some, in my eyes, seriously infelicitous design choices given its target market and likely duties.

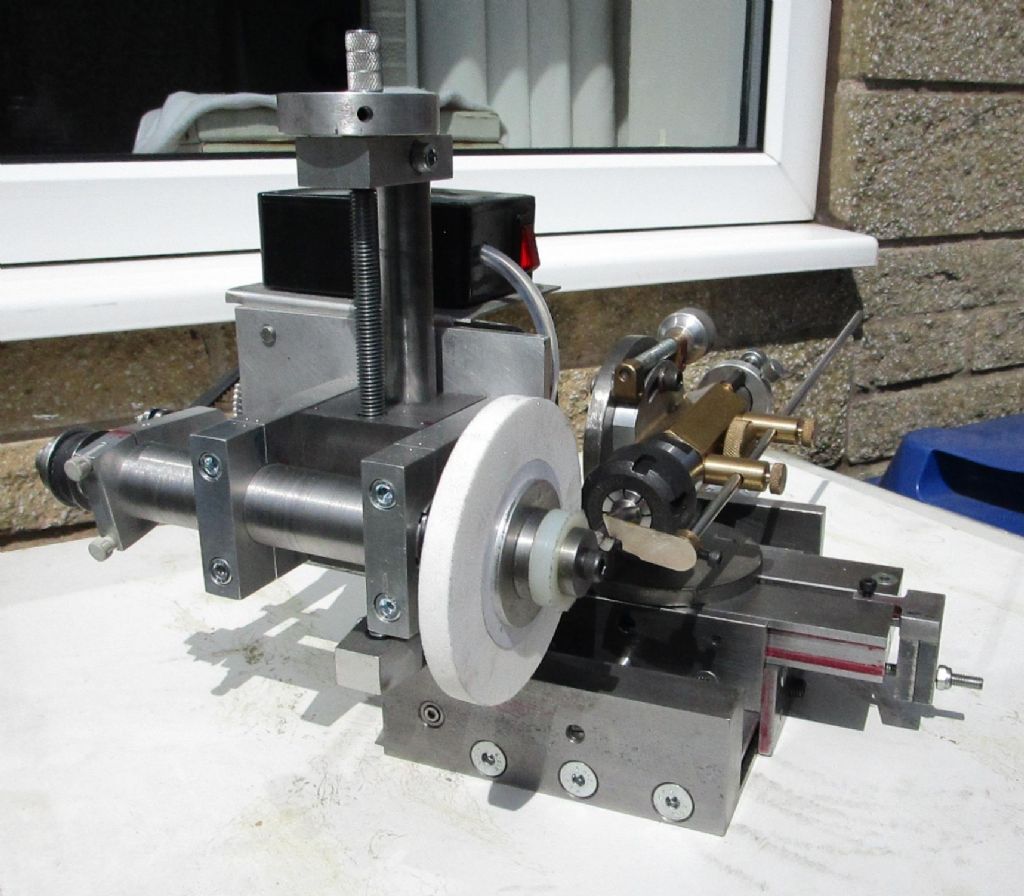

The Bonelle is a Quorn re-worked to be made form stock materials and is said to be a much faster build with some advantages in use. It carries the wheel head on a simple column with an elevating screw alongside, a much easier build than the Quorn column. Soemthing you could easily copy.

I considered the Stent and other casting kits but decided the cost of the castings was more than I was prepared to pay. The Stent also sprawls taking up a fair bit of bench space. I felt the Worden was too limited as were a variety of simple one trick pony end mill and similar sharpeners.

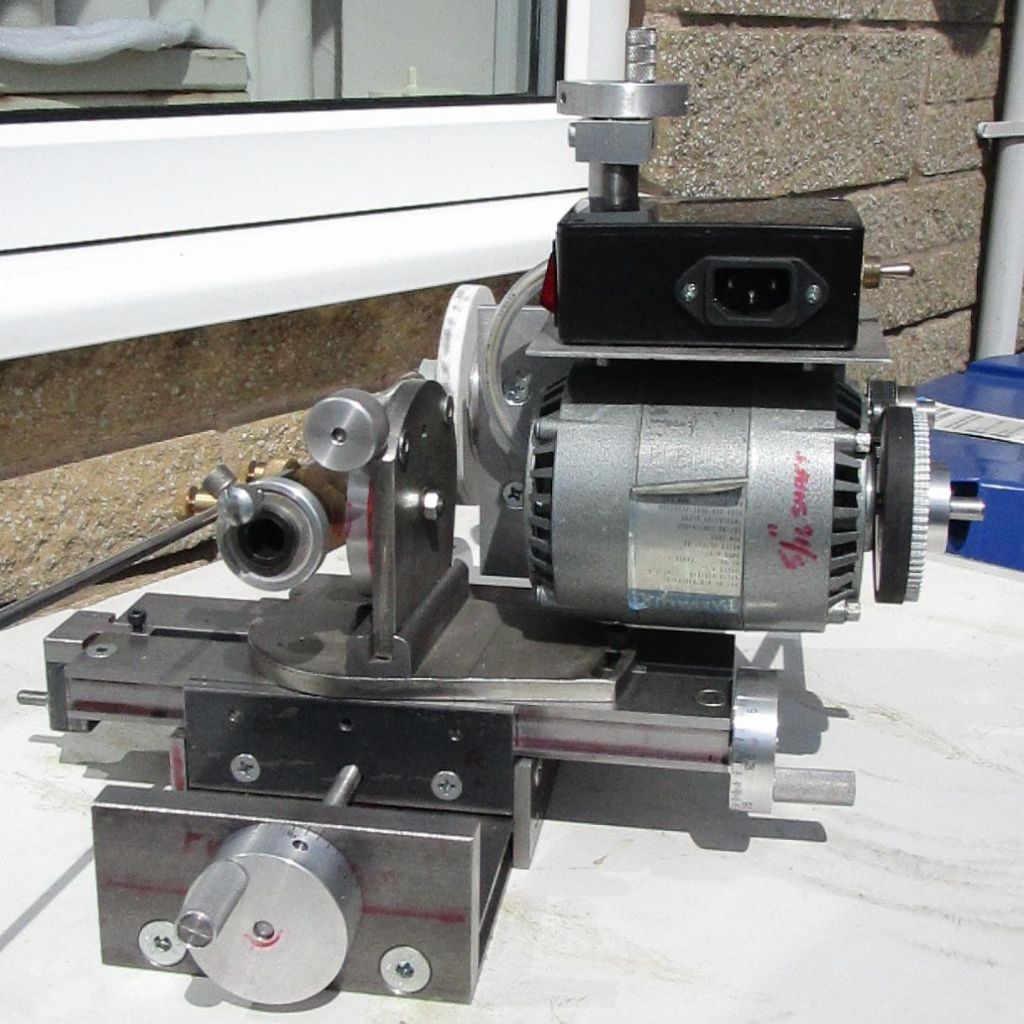

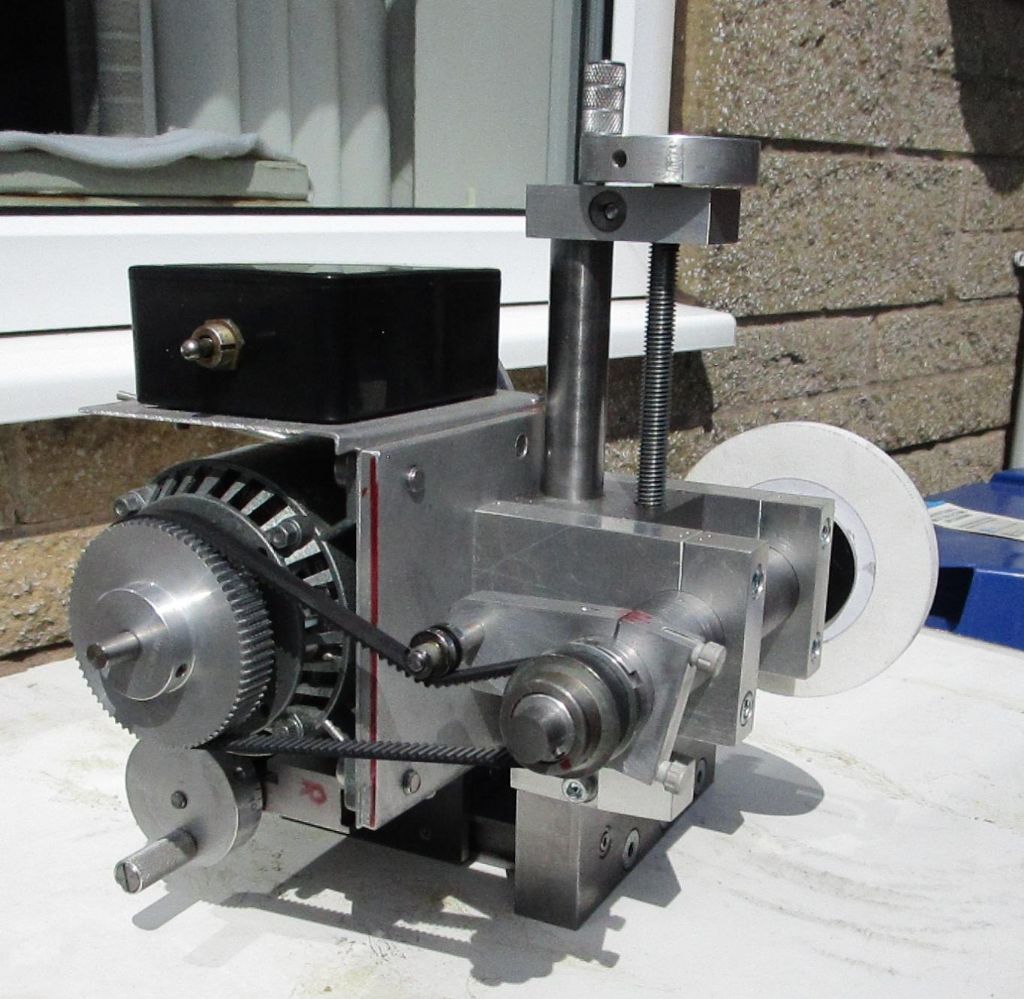

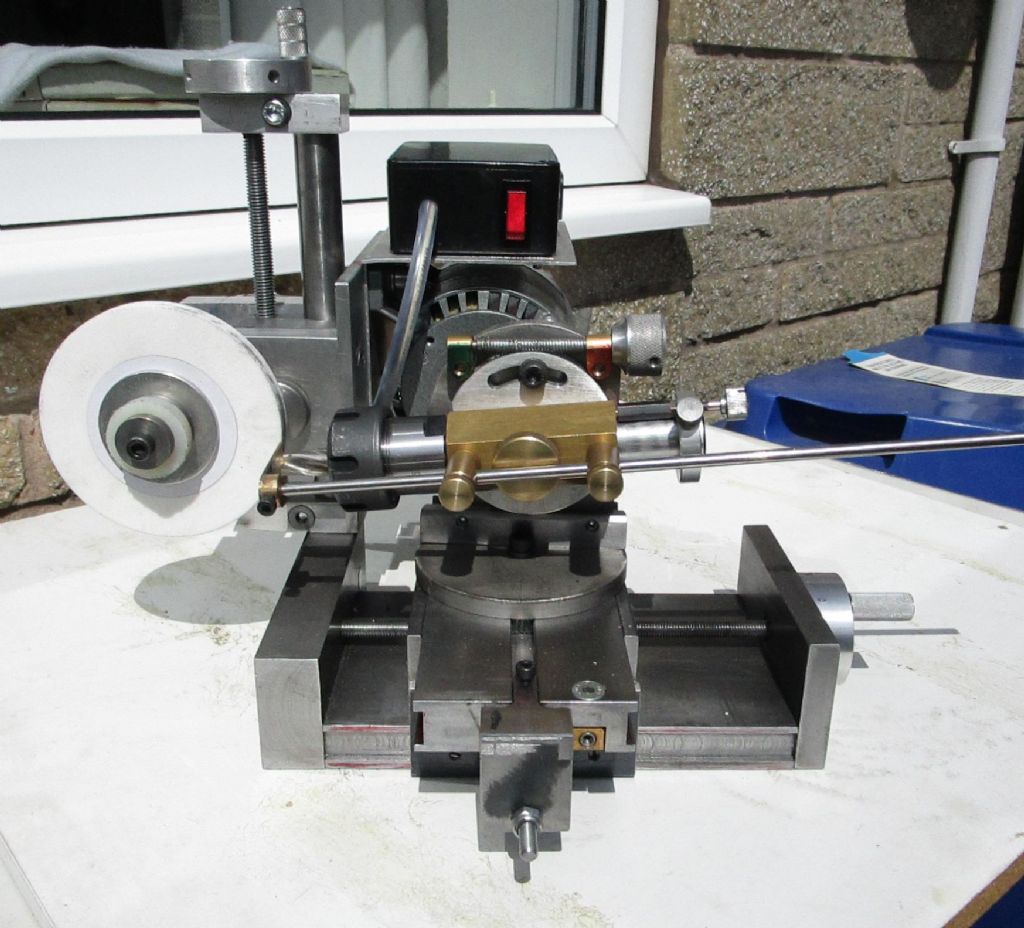

I eventually settled on a design by Derek Brooks published in the April / May and June/July issues of MEW for 1993 as offering a decent balance of build effort and capabilities. In particular it combines a simple column to carry the wheel head with an elegantly simple way of building the X-Y table and a decently simple set of work holders. Its capabilities are basically that of a small Clarkson albeit without the extra versatility given by the rotating table carrier on the real thing. Derek also provided a decent guide to using it.

As Sam already has his X-Y table he can save much effort and simply copy the other parts of the design. The X (long) axis feed needs to be converted to lever action. Derek used a chain which is simple and effective.

One thing I've never understood about published designs is why no one seems to have copied the Clarkson layout. The simple see-saw motor and wheel-head support used on the Clarkson makes it far easier to achieve decent mechanical stability than the usual column. If a self contained wheel head (small bench grinder) is desired a single sided pivot arm makes a straightforward change. Much to be said for the Clarkson rotating table mount which makes a lot of set-ups easier than rotating a wheel head around a column. The rotating table mout is of course made essential by the Clarksons fixed wheel head carrier.

In the end a Clarkson appeared at a "wallet came out smoking" price so I never built a T & C grinder.

Clive

noel shelley.